When comparing diaphragm and piston pumps, you’ll find diaphragm pumps are simpler, more leak-free, and ideal for handling corrosive or sensitive fluids with lower maintenance costs. Piston pumps deliver higher pressure and flow rates, making them suitable for demanding applications like high-pressure cleaning or fuel injection. Each offers distinct advantages based on your needs, so understanding their differences can help you choose the right fit. Keep exploring to discover which pump best matches your specific requirements.

Key Takeaways

- Diaphragm pumps use flexible diaphragms for sealing, ideal for corrosive and abrasive fluids, while piston pumps use reciprocating pistons for high-pressure applications.

- Diaphragm pumps are simpler, easier to maintain, and operate quietly, whereas piston pumps typically offer higher pressure and flow rates.

- Material compatibility and corrosion resistance are critical for diaphragm pumps handling sensitive or hazardous fluids; piston pumps excel in durability under high pressure.

- Diaphragm pumps are suitable for sterile, chemical, and food processing, while piston pumps are preferred in automotive and industrial high-pressure systems.

- Operating principles differ: diaphragm movement creates fluid flow through flexible sealing, while piston reciprocation generates pressure through mechanical force.

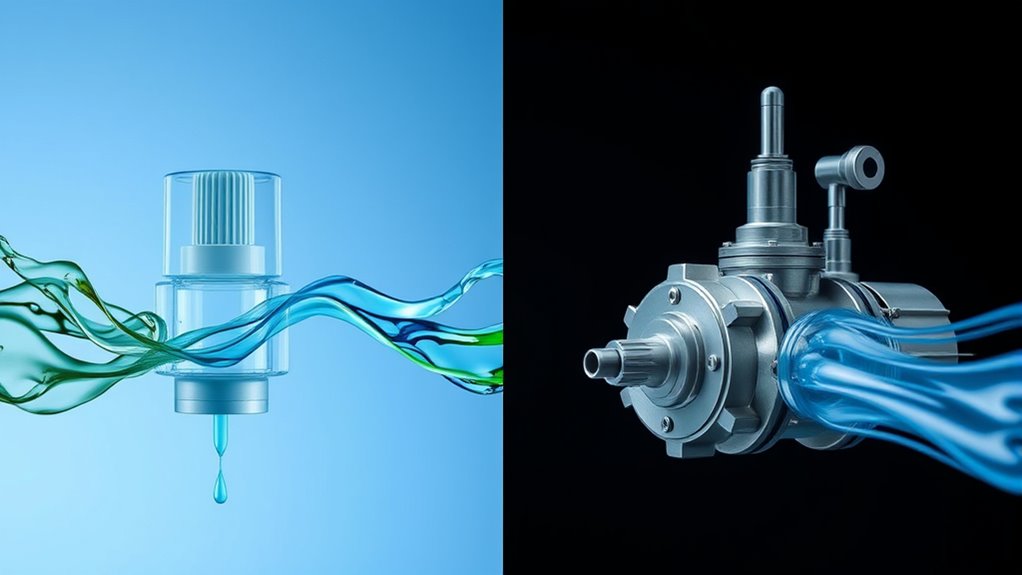

Basic Design and Operating Principles

Diaphragm and piston pumps differ markedly in their basic design and operating principles, which directly impact their performance and applications. You’ll notice that diaphragm pumps feature a design simplicity that makes them easy to maintain and operate. Their operating mechanism uses a flexible diaphragm that moves back and forth, creating a sealed chamber that draws in and expels fluid. Piston pumps, on the other hand, rely on a reciprocating piston within a cylinder. This piston’s movement—driven by a crankshaft or similar mechanism—generates pressure and flow. The operating mechanism in piston pumps involves precise, mechanical motion, often resulting in higher pressure capabilities. Overall, the fundamental differences in design simplicity and operating mechanisms shape how these pumps are used and their efficiency in various applications. Additionally, piston pumps are often preferred in high-pressure applications, where their ability to generate greater force is essential. The choice between the two also depends on factors like maintenance requirements and operational environment. Understanding performance characteristics helps in selecting the appropriate pump type for specific needs. Furthermore, the material compatibility and fluid handling capacity are critical considerations when choosing between these pump types. For example, diaphragm pumps are often better suited for handling corrosive or abrasive fluids due to their design.

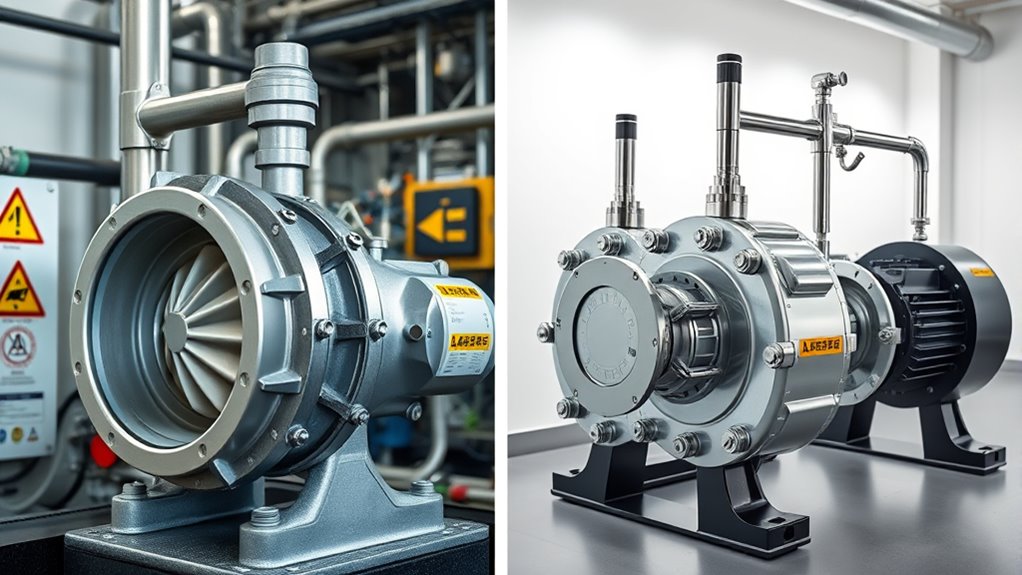

Applications and Industry Usage

You’ll find diaphragm and piston pumps in many industries, each suited for specific needs. Chemical processing often depends on these pumps to handle corrosive or hazardous materials safely. In the food and beverage sector, they guarantee hygiene and precise fluid transfer for quality control. Additionally, these pumps are frequently utilized in medical and pharmaceutical applications due to their ability to maintain sterile conditions and prevent cross-contamination using specialized materials. Understanding the personality traits of operators can also influence the effectiveness and safety of pump operation in these sensitive environments. Moreover, adopting technological innovations can optimize pump performance and maintenance practices. The selection between diaphragm and piston pumps depends heavily on the specific industry requirements and operational conditions.

Industry-Specific Applications

Because different industries have unique requirements for fluid handling, selecting the right pump technology can considerably impact efficiency and reliability. In biotech applications, diaphragm pumps are favored for their ability to handle sensitive, sterile fluids without contamination, making them ideal for laboratory and pharmaceutical processes. They are also valued for their corrosion resistance, which ensures longevity when working with aggressive chemicals. Additionally, diaphragm pumps often feature self-priming capabilities, enabling reliable operation even when starting with air or low fluid levels. Furthermore, their compact design allows for easier integration into various laboratory setups and constrained spaces. The versatility of diaphragm pumps makes them suitable for a variety of applications, from delicate fluid transfer to high-volume processing. Automotive systems often rely on piston pumps for their durability and high-pressure capabilities, essential for fuel injection, cooling, and lubrication. Diaphragm pumps excel when precise dosing and leak-free operation are needed, especially with corrosive or viscous fluids. Conversely, piston pumps are preferred where high flow rates and pressure are critical, such as in manufacturing and assembly lines. Understanding these industry-specific needs helps you choose the most suitable pump type, ensuring seamless operation and long-term performance. Additionally, the maintenance requirements of each pump type can influence operational costs and downtime, so selecting a design aligned with industry standards is crucial.

Chemical Processing Uses

In chemical processing, selecting the right pump technology is crucial for handling corrosive, viscous, or reactive fluids safely and efficiently. Diaphragm pumps are favored for their low pump noise and excellent chemical resistance, making them ideal for sensitive or hazardous environments. Piston pumps, on the other hand, often feature a smaller installation size, which can be advantageous in limited spaces. Both pump types provide precise flow control indispensable for complex chemical reactions. Your choice depends on your specific needs: diaphragm pumps excel in applications requiring leak-free operation and durability, while piston pumps offer high pressure and flow rates in compact setups. Considering these factors ensures safe, efficient processing, reducing maintenance and operational costs over time.

Food and Beverage Industry

In the food and beverage industry, selecting the right pump technology is essential to guarantee product quality, safety, and hygiene. Pump efficiency directly impacts production speed and energy costs, so choosing a pump that maximizes output while minimizing waste is crucial. Diaphragm pumps excel here because they provide consistent flow with minimal pulsation, ensuring product integrity. Piston pumps, while efficient, may generate higher noise levels, which can affect working conditions and overall plant operation. Noise levels matter in maintaining a comfortable environment and preventing contamination. When comparing the two, consider how pump efficiency and noise levels influence your process. Opting for a pump that balances these factors will help you meet industry standards and keep production running smoothly. Additionally, understanding the importance of maximizing space and organization can help optimize your plant layout and workflow for better efficiency. Proper pump selection also involves evaluating pump maintenance requirements, which can impact overall operational costs and downtime.

Material Compatibility and Corrosion Resistance

You need to ensure how pump materials withstand harsh conditions and resist corrosion over time. Choosing components that are compatible with your fluids ensures durability and reduces maintenance costs. Understanding these aspects helps you select a pump that performs reliably in your specific application. Incorporating industry trends can also guide you toward more innovative and resilient material choices. Additionally, considering practical support options can aid in maintenance and long-term operation. Recognizing the importance of material compatibility and corrosion resistance is essential for optimizing pump performance in challenging environments. Staying informed about material testing methods can further enhance your ability to select appropriate materials for your pump needs. Moreover, staying updated on corrosion-resistant coatings can significantly extend the lifespan of pump components in corrosive environments.

Pump Material Durability

Choosing the right pump material is essential because it directly impacts the pump’s durability and performance over time. You need materials that withstand wear, chemical exposure, and environmental factors, guaranteeing longevity. When selecting materials, consider biocompatibility issues if the pump contacts sensitive substances or environments, preventing contamination or adverse reactions. Additionally, the material’s aesthetic design can influence your choice, especially in applications where appearance matters. Durable materials like stainless steel or certain plastics resist cracking, corrosion, and fatigue, maintaining integrity under continuous use. Piston pumps often use more robust materials to handle higher pressures, while diaphragm pumps focus on flexible, chemically resistant materials. It’s important to also consider the material durability and how it aligns with the specific application requirements for optimal performance. Moreover, considering Aromatherapy oils compatibility is crucial since some oils can be corrosive or degrade certain materials over time. Overall, prioritizing material durability ensures your pump remains reliable, efficient, and safe throughout its lifespan.

Corrosion-Resistant Components

Selecting components that resist corrosion is critical to guaranteeing your pump maintains ideal performance over time. Using biocompatible materials helps prevent chemical reactions that could degrade parts, especially in sensitive applications. These materials enhance corrosion resistance, prolonging component lifespan and reducing maintenance needs. Corrosion-resistant components also contribute to noise reduction by maintaining tight seals and stable operation. When choosing between diaphragm and piston pumps, consider how their materials interact with your fluid and environment. Opting for corrosion-resistant parts ensures your pump operates reliably, minimizes downtime, and maintains efficiency. Proper material selection is essential for long-term performance, especially in demanding or corrosive conditions. Ultimately, investing in corrosion-resistant, biocompatible components safeguards your equipment and ensures smooth, quiet operation.

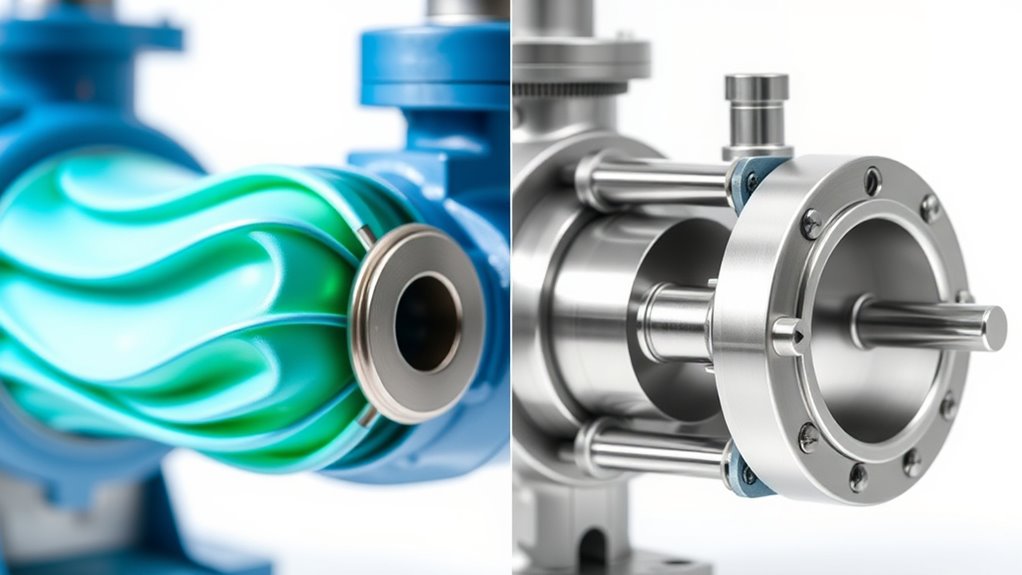

Compatibility With Fluids

Material compatibility between pump components and the fluids they handle plays a vital role in maintaining ideal performance. If the fluid has high viscosity, you’ll need materials that can withstand the increased pressure and shear forces without degrading. Similarly, fluids with corrosive properties require corrosion-resistant materials, regardless of pump size. Diaphragm pumps often use flexible, chemically resistant diaphragms suitable for aggressive fluids, while piston pumps may require metal or specialized coatings. Choosing the right materials ensures longevity and prevents failures. Keep in mind that fluid viscosity influences material choice, as thicker fluids may cause more wear on certain components. Proper compatibility minimizes maintenance, avoids leaks, and guarantees consistent operation, regardless of the fluid’s properties.

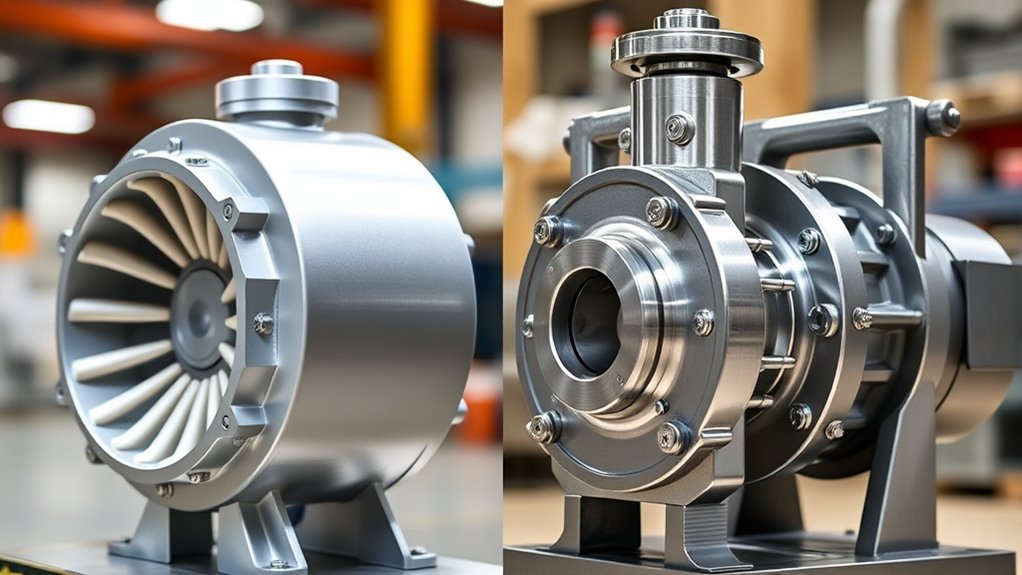

Pressure and Flow Capabilities

Are you wondering how diaphragm and piston pumps compare when it comes to pressure and flow capabilities? Generally, piston pumps excel in delivering higher pressure and greater flow rates, making them suitable for demanding applications. Diaphragm pumps, however, offer better pressure consistency and flow stability, especially with fluctuating demands. Consider these key points:

- Piston pumps handle peak pressures efficiently but may experience pressure fluctuations.

- Diaphragm pumps maintain steady pressure, ideal for sensitive processes.

- Flow rates in piston pumps tend to be higher but can vary under load.

- Diaphragm pumps provide consistent flow, reducing pulsation and improving process control.

Understanding these differences helps you select the right pump based on your pressure and flow needs.

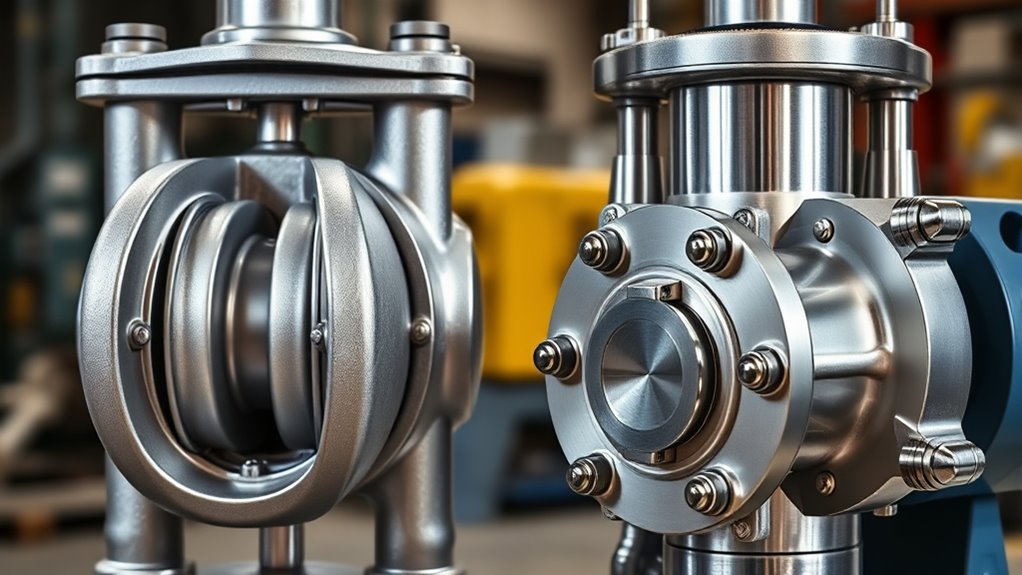

Sealing and Leak Prevention

Because sealing integrity is crucial for preventing leaks and ensuring reliable operation, understanding how diaphragm and piston pumps handle sealing is essential. Diaphragm pumps use flexible membranes with sealing techniques that create a tight barrier, minimizing leak points. This design offers excellent leak prevention methods, especially in handling abrasive or corrosive fluids. Piston pumps rely on piston seals and packing glands, which must withstand high pressure and motion. Proper sealing techniques, such as applying appropriate gasket materials and maintaining tight clearances, are critical to prevent leaks. Both pump types incorporate leak prevention methods tailored to their mechanisms. While diaphragm pumps typically provide better leak resistance due to their sealed chambers, piston pumps require regular inspection of seals to ensure continued integrity. Your choice depends on your specific application’s sealing demands.

Maintenance and Durability

When it comes to maintenance and durability, you’ll notice that diaphragm pumps generally resist wear better and require less frequent upkeep. Piston pumps, on the other hand, may need more attention over time but can offer longer-lasting performance with proper care. Understanding these differences helps you choose the right pump for reliable, long-term operation.

Wear Resistance Differences

While both diaphragm and piston pumps are designed for durability, their wear resistance varies substantially due to their different operational mechanisms. Your pump’s lifespan depends heavily on factors like abrasion resistance and surface hardness. Diaphragm pumps typically offer better abrasion resistance because of their flexible diaphragm, which absorbs impacts. Piston pumps, with their rigid components, rely on high surface hardness to resist wear from constant movement. Key differences include:

- Diaphragm materials often have superior abrasion resistance

- Piston surfaces are hardened for durability

- Diaphragms experience less surface wear overall

- Piston wear depends on the hardness and lubrication

Understanding these differences helps you select a pump suited for demanding applications where wear resistance prolongs service life.

Ease of Maintenance

Maintaining diaphragm pumps is generally simpler than servicing piston pumps, thanks to their fewer moving parts and straightforward design. You’ll find fewer components to lubricate, reducing maintenance time. Piston pumps often have higher noise levels, making regular inspections more noticeable but also more necessary. Here’s a quick comparison:

| Aspect | Diaphragm Pump | Piston Pump |

|---|---|---|

| Lubrication requirements | Minimal, self-lubricating | Frequent, requires lubrication |

| Noise levels | Lower, quieter | Higher, noisier |

| Ease of maintenance | Simple, quick access | More complex, parts harder to reach |

| Durability | Generally durable | Can be more prone to wear |

This simplicity means less downtime and easier troubleshooting, saving you time and effort.

Long-term Durability

Diaphragm pumps often outperform piston pumps in long-term durability due to their simpler construction and fewer moving parts. This means less wear and tear over time, reducing maintenance needs and extending operational life. You’ll notice they typically generate less pump noise, which is beneficial in noise-sensitive environments. Additionally, diaphragm pumps usually have lower installation complexity, making them easier to set up and maintain long-term. Piston pumps, with their more complex mechanisms, are prone to more frequent failures and increased downtime. Consider these points for durability:

- Fewer moving parts reduce wear

- Less pump noise over time

- Easier to maintain due to simpler design

- Lower installation complexity enhances reliability

Cost Factors and Initial Investment

When comparing diaphragm and piston pump technologies, the initial investment and cost factors play a essential role in your decision-making process. Diaphragm pumps typically have a lower initial cost, making them attractive for startups or budget-conscious projects. Piston pumps, however, often require a higher upfront investment due to their complex design and materials. Operational expenses also differ; diaphragm pumps usually have lower maintenance costs and simpler parts, reducing long-term expenses. Piston pumps may incur higher costs over time because of more frequent repairs and parts replacement. Consider your budget carefully—if initial cost is a priority, diaphragm pumps could be more suitable. But for applications demanding higher precision and durability, the higher initial investment in piston pumps might be justified by lower operational expenses over their lifespan.

Precise Dosing and Fluid Handling

Choosing the right pump technology substantially impacts how accurately and reliably you can dose fluids. For biological fluid transfer, precision is essential to maintain sample integrity and consistency. Diaphragm pumps excel in delivering consistent doses, thanks to their pneumatic actuation, which offers fine control. Piston pumps can also provide accurate fluid handling but may require more maintenance for complex dosing tasks. Consider these factors:

Diaphragm pumps offer precise, reliable dosing ideal for sensitive biological fluids.

- Consistent flow rates for biological fluids

- Precise control over small doses

- Reliability in repetitive operations

- Compatibility with various fluid viscosities

Both technologies support precise dosing, but diaphragm pumps often deliver smoother, more controlled transfer, especially in sensitive applications. Your choice depends on the required accuracy, fluid properties, and operational demands.

Safety and Environmental Considerations

While selecting a pump technology, safety and environmental impacts should be top priorities, especially in sensitive applications. Diaphragm pumps are generally safer because they minimize the risk of chemical leaks, thanks to their sealed design that prevents fluid contact with moving parts. Piston pumps, on the other hand, can pose higher risks if seals fail or maintenance isn’t properly maintained, leading to potential chemical leaks. Both pump types can impact the environment if leaks occur, but diaphragm pumps often have a smaller environmental footprint due to reduced leak potential. Choosing a pump with reliable sealing and leak detection features helps protect workers and reduces environmental impact. Prioritizing safety and environmental considerations ensures compliance and minimizes risks in your operations.

Choosing the Right Pump for Your Needs

Selecting the right pump depends on evaluating your specific application needs, including the type of fluid, flow rate, pressure requirements, and operating environment. Consider how pump noise might impact your workspace, especially in quiet settings. Energy efficiency is also critical, as it affects operational costs and sustainability. For instance, diaphragm pumps often operate more quietly and with lower energy use, making them suitable for sensitive environments. Piston pumps, while powerful, tend to generate more noise and consume more energy, but they excel in high-pressure applications. To choose wisely, assess these factors carefully:

- Pump noise levels

- Energy efficiency

- Fluid compatibility

- Pressure and flow demands

Frequently Asked Questions

How Do Diaphragm and Piston Pumps Compare in Energy Efficiency?

When considering energy consumption, the efficiency comparison reveals that diaphragm pumps often use less energy for handling fluids with high viscosity or containing solids, as they operate with less slip and fewer leaks. Piston pumps, however, may deliver higher efficiency in high-pressure applications but typically consume more energy due to their more complex mechanisms. Your choice depends on your application’s specific needs for energy efficiency and operational demands.

Are There Specific Industries Where One Pump Type Is Preferred?

In chemical processing and pharmaceutical manufacturing, choosing the right pump depends on your needs. For precise, sterile, and contamination-free transfer, diaphragm pumps are often preferred due to their gentle handling and compatibility with corrosive fluids. Piston pumps, on the other hand, excel in high-pressure applications requiring robust, efficient performance. Your industry’s specific requirements will guide you toward the most suitable pump type for ideal operation.

What Are the Typical Maintenance Intervals for Each Pump?

You should follow the maintenance schedules for each pump type to guarantee peak performance. Diaphragm pumps typically need inspections every 3 to 6 months, focusing on checking for wear and tear. Piston pumps may require more frequent maintenance, around every 1 to 3 months, especially for lubrication requirements. Regular lubrication and timely part replacements help prevent breakdowns and extend the lifespan of both pump types.

How Do Diaphragm and Piston Pumps Handle Abrasive Fluids?

Handling abrasive fluids can feel intimidating, but choosing the right pump makes all the difference. Diaphragm pumps excel in abrasive fluid handling, thanks to their flexible, durable materials that promote pump material compatibility. Piston pumps can also handle abrasives if equipped with wear-resistant components. Ultimately, selecting a pump designed for your specific abrasive fluid, with proper maintenance, guarantees reliable operation and prolongs equipment life.

Can These Pumps Be Easily Integrated With Automation Systems?

You can easily integrate diaphragm and piston pumps with automation systems, thanks to their control compatibility. Many models feature digital interfaces and adaptable controls, making it simple to connect with existing systems. Additionally, retrofit options are available, allowing you to upgrade your current pumps without complete replacements. This flexibility guarantees smooth automation integration, improving efficiency and process control without significant disruptions or costs.

Conclusion

Choosing between a diaphragm and piston pump is like selecting the right key for a lock—you need the perfect fit. Your decision shapes the flow of your operation, symbolizing control, reliability, and efficiency. Trust your needs to guide you, opening seamless performance and safeguarding your process. Ultimately, the right pump isn’t just machinery; it’s the key to revealing your project’s full potential. Make your choice wisely, and let your system flow smoothly.