To properly lubricate the moving parts in your airless sprayer, select a light-weight oil or lubricant recommended by the manufacturer for spray guns and pumps. Focus on pivot points, trigger mechanisms, and pump seals, applying just enough to reduce friction without causing build-up. Regularly inspect for squeaks or resistance, and reapply as needed. Following these steps helps keep your equipment running smoothly—stay tuned for more tips on maintaining ideal performance.

Key Takeaways

- Use lubricants specifically designed for spray guns and pumps, such as light-weight oils or synthetic lubricants.

- Focus lubrication on pivot points, trigger mechanisms, and pump seals to reduce friction and wear.

- Follow the manufacturer’s recommended lubrication schedule based on usage and operating conditions.

- Apply lubricants carefully to avoid excess that can attract dirt and cause clogs or damage.

- Regularly inspect for signs of friction or squeaking and reapply lubricant as part of routine maintenance.

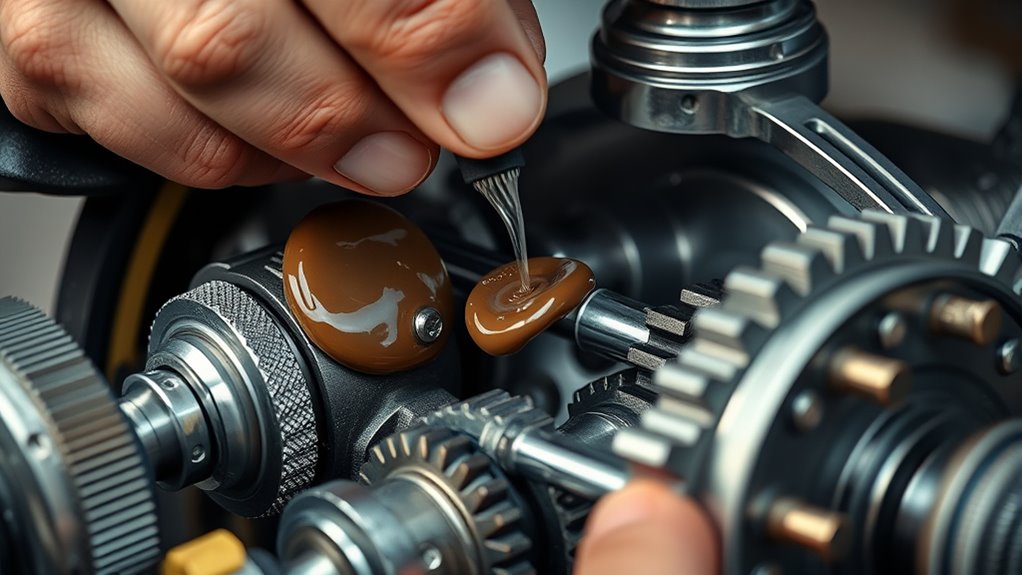

Proper lubrication of moving parts in airless sprayers is essential to guarantee smooth operation and extend the equipment’s lifespan. When you keep your sprayer well-lubricated, it reduces friction, prevents wear, and minimizes the risk of breakdowns. To achieve this, you need to pay attention to lubrication frequency, which determines how often you should apply lubricant based on usage and operating conditions. Regularly checking your equipment and maintaining a consistent lubrication schedule helps ensure all moving parts stay properly coated. Typically, if you’re using your sprayer daily or in demanding environments, you might need to lubricate more frequently—perhaps after every few hours of operation. Conversely, for occasional use, a weekly or bi-weekly check might suffice. The key is to observe signs of friction or squeaking and respond promptly.

Choosing the right types of lubricants plays a crucial role in maintaining your airless sprayer. Not all lubricants are suitable for this kind of equipment, so it’s important to select products designed specifically for spray guns and pumps. Generally, lightweight oils or lubricants labeled for pneumatic tools work well because they provide the necessary lubrication without attracting dirt or debris. You might also consider synthetic lubricants, which tend to last longer and perform better under high pressure and temperature conditions. Avoid using heavy greases or general-purpose oils that aren’t formulated for delicate moving parts, as they can cause build-up or damage. When applying the lubricant, make sure to target the pivot points, trigger mechanisms, and pump seals—areas where friction is most likely to cause wear. Additionally, using proper lubrication techniques can further enhance the longevity of your equipment.

Establishing a routine for lubrication not only keeps your sprayer running smoothly but also extends its overall working life. Before each use, take a few moments to inspect the device and apply fresh lubricant where needed. If you notice any squeaking or increased resistance during operation, it’s a sign that lubrication is overdue. Remember, proper lubrication isn’t a one-time task; it’s an ongoing process that requires your attention. Use only recommended lubricants, follow the manufacturer’s instructions carefully, and avoid over-lubricating, as excess oil can attract dirt and clog the system. By maintaining a consistent lubrication schedule and choosing the correct types of lubricants, you’ll keep your airless sprayer performing efficiently, saving you time and costly repairs in the long run.

Frequently Asked Questions

How Often Should I Check the Lubrication Levels?

You should check the lubrication levels daily as part of your regular maintenance routines, especially if you’re using the sprayer frequently. Following proper lubrication schedules helps prevent wear and tear on moving parts. Always inspect the lubrication points before each job, and reapply lubricant as needed. Staying consistent with these checks guarantees your airless sprayer runs smoothly, reducing downtime and extending its lifespan.

Can I Use Any Type of Oil for Lubrication?

Is your airless sprayer’s moving parts crying out for help? Don’t just grab any oil—think of oil types as a perfect dance partner, each with its own rhythm. You need lubrication compatibility to guarantee smooth performance. Using the wrong oil can cause damage, so stick to manufacturer-recommended lubricants. With the right oil, your sprayer will glide like a well-choreographed performance, lasting longer and working better.

What Are Signs of Insufficient Lubrication?

You’ll notice signs of insufficient lubrication, like squeaking or grinding noises, increased friction, or overheating of parts. Regularly following your maintenance schedule and using the correct lubrication types, such as specific oils recommended for your sprayer, helps prevent these issues. If you ignore lubrication needs, parts may wear out faster, leading to costly repairs. Always monitor your equipment and re-lubricate as per the manufacturer’s guidelines to keep it running smoothly.

Is Lubrication Necessary After Every Use?

Just like a well-tuned orchestra, your airless sprayer needs regular care. You should lubricate after every use to guarantee smooth operation, especially if it’s been exposed to dirt or moisture. Focus on lubrication frequency and choose the right oil, preferably one recommended by the manufacturer. This keeps parts moving seamlessly, prevents wear, and prolongs your sprayer’s life, much like a maestro maintaining harmony in a symphony.

How Do I Access Lubrication Points Safely?

To access lubrication points safely, first turn off and unplug your sprayer, then wear safety gloves and glasses. Follow safety precautions by reviewing the user manual for specific lubrication points. Use appropriate lubrication tools, like a grease gun or brush, to apply lubricant precisely. Carefully clean around the lubrication areas to prevent debris from contaminating the components. Always guarantee the machine is stable before working on it to avoid accidents.

Conclusion

Now that you know how to properly lubricate your airless sprayer’s moving parts, you might think your job’s done. But here’s the twist—neglecting this step could lead to unexpected downtime when you least expect it. Keep the lubrication routine consistent, and you’ll avoid surprises. Are you ready to master this simple yet essential task? The next time you spray, remember—proper lubrication could be the difference between smooth operation and a costly breakdown.