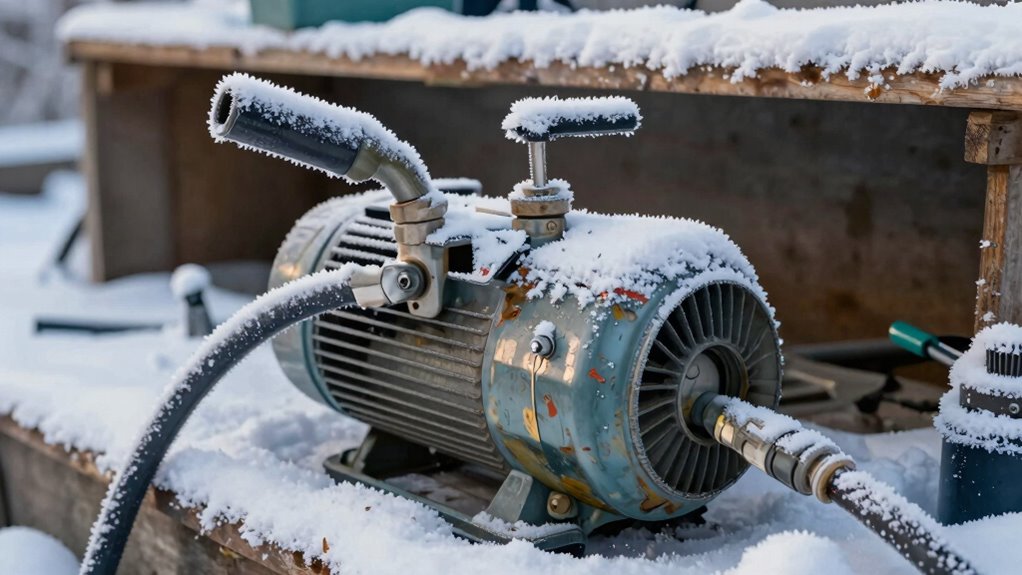

One common mistake that can ruin your airless pump during winter is neglecting proper insulation and sealing. If you leave gaps around doors, windows, or vents, cold air will seep in, causing temperature fluctuations that can freeze internal parts or crack hoses. Without adequate insulation, your equipment is vulnerable to moisture buildup, rust, and damage. Ensuring a well-insulated, sealed environment can prevent costly problems—keep going to discover more essential winter storage tips.

Key Takeaways

- Failing to insulate pipes and equipment, exposing them to freezing temperatures that cause cracks and internal damage.

- Not sealing gaps around doors, windows, or vents, allowing cold drafts and moisture buildup that corrode internal components.

- Using inadequate insulation materials or leaving areas uninsulated, leading to temperature fluctuations and equipment freezing.

- Neglecting to elevate pumps off the floor or cover them properly, increasing exposure to dampness and condensation damage.

- Ignoring regular inspection and maintenance of insulation and seals, which can lead to unnoticed deterioration and eventual equipment failure.

Winter storage can be tricky, and many people make simple mistakes that lead to costly damage come spring. One of the most common errors is neglecting proper insulation and sealing around your airless pump. If your storage area isn’t sufficiently insulated, your equipment is exposed to drastic temperature swings that can cause internal parts to freeze or become brittle. Without adequate insulation, cold air seeps in through walls, floors, or ceilings, creating a harsh environment that accelerates wear and tear. This oversight often results in cracked hoses, damaged seals, or even complete pump failure once temperatures drop below freezing.

Neglecting insulation and sealing risks freezing, cracking, and damaging your airless pump during winter.

Improper sealing compounds the problem. If you don’t seal gaps, cracks, or openings around windows, doors, or vents, cold drafts can infiltrate your storage space. These drafts not only lower the ambient temperature but also create uneven heating zones, which can cause condensation and moisture buildup inside your equipment. Moisture is especially damaging to airless pumps because it can corrode internal components, leading to rust and malfunction. Without proper sealing, you risk exposing your equipment to fluctuating humidity levels, which further accelerates deterioration and reduces the lifespan of your pump.

To avoid these mistakes, you should focus on creating a well-insulated environment. Use quality insulation materials like foam board, spray foam, or fiberglass batts to cover walls and floors. Ensure that all potential entry points for cold air are sealed tight with weatherstripping, caulk, or expanding foam. Pay special attention to areas around windows, doors, and vents, as these are common sources of drafts. Proper sealing isn’t just about keeping the cold out; it also helps maintain a stable temperature inside, protecting your equipment from thermal stress.

Additionally, installing a temperature monitoring system can help you keep an eye on environmental conditions and prevent unintentional exposure to damaging cold temperatures. Furthermore, you should consider elevating your airless pump off the floor, especially if the storage space is prone to dampness or poor insulation. Placing the equipment on pallets or shelves prevents contact with cold, damp surfaces that can accelerate corrosion. Also, covering your pump with a breathable tarp or cover can help protect it from dust and moisture without trapping condensation inside.

In essence, the key to safeguarding your airless pump during winter is paying attention to insulation and sealing. It’s a simple step that can save you a lot of money and frustration in the long run. A well-insulated, tightly sealed storage space creates a stable environment, preventing the damage caused by freezing temperatures and moisture. Don’t overlook these details—your equipment’s longevity depends on it.

Frequently Asked Questions

Can Airless Pumps Be Stored Outdoors During Winter?

You shouldn’t store airless pumps outdoors during winter. Outdoor storage exposes the pump to harsh weather and temperature fluctuations, which can damage its components. Make sure you keep it in a sheltered, temperature-controlled environment to prevent freezing or cracking. Always consider temperature considerations when storing your pump, and avoid leaving it outside in cold weather to extend its lifespan and maintain peak performance.

How Does Cold Weather Affect Pump Seals and Internal Components?

Cold weather causes thermal contraction in your airless pump’s seals and internal parts, making them brittle and more prone to cracking. This seal degradation can lead to leaks or pump failure. When storing your pump in low temperatures, avoid exposing it to harsh winter conditions, and consider insulating or storing it indoors. Proper winter storage prevents damage caused by thermal contraction, ensuring your pump stays functional and lasts longer.

Should I Drain All Paint From the Pump Before Winter?

Coincidentally, draining all paint from your pump before winter is a smart move. Leaving paint residue inside can lead to pump corrosion and blockages, ruining your equipment. By emptying the pump, you prevent paint from drying and causing internal damage. Plus, it’s easier to clean and store. So, yes, you should drain all paint thoroughly to safeguard your airless pump and ensure it’s ready for use when spring arrives.

What Are the Signs of Damage Caused by Winter Storage?

You’ll notice signs of damage from winter storage like winter corrosion on metal parts and seal deterioration, which can cause leaks or inconsistent spray patterns. Cracks or stiffness in seals indicate they’ve been compromised, and rust or corrosion spots on the pump suggest moisture has caused damage. If you see these issues, it’s a clear sign that your airless pump has suffered from improper winter storage and needs repair or replacement.

Is It Necessary to Lubricate the Pump Before Winter Storage?

Yes, lubricating your airless pump before winter storage is essential for proper pump maintenance. The lubrication importance lies in preventing parts from seizing or corroding during cold months. You should apply a suitable lubricant to moving components, ensuring they stay in good condition. This simple step helps avoid damage caused by freezing or corrosion, making sure your pump stays functional and ready for use when spring arrives.

Conclusion

If you ignore winter storage tips, you risk ruining your airless pump just like leaving a delicate plant out in a freezing storm. I once saw a painter’s pump shattered after a cold snap—proof that neglect can turn a simple tool into trash. Think of your pump as a trusted friend: give it proper winter care, or it might let you down when you need it most. Protect it now to avoid costly replacement later.