Airless line stripers are designed specifically for pavement markings, using high-pressure pumps to spray paint precisely without compressed air. Unlike standard paint sprayers meant for furniture or walls, they produce durable, sharp lines for parking lots, crosswalks, and safety markings. Their construction resists wear and offers adjustable spray widths for accuracy. If you want to understand how these differences affect their performance and applications, you’ll find more useful details ahead.

Key Takeaways

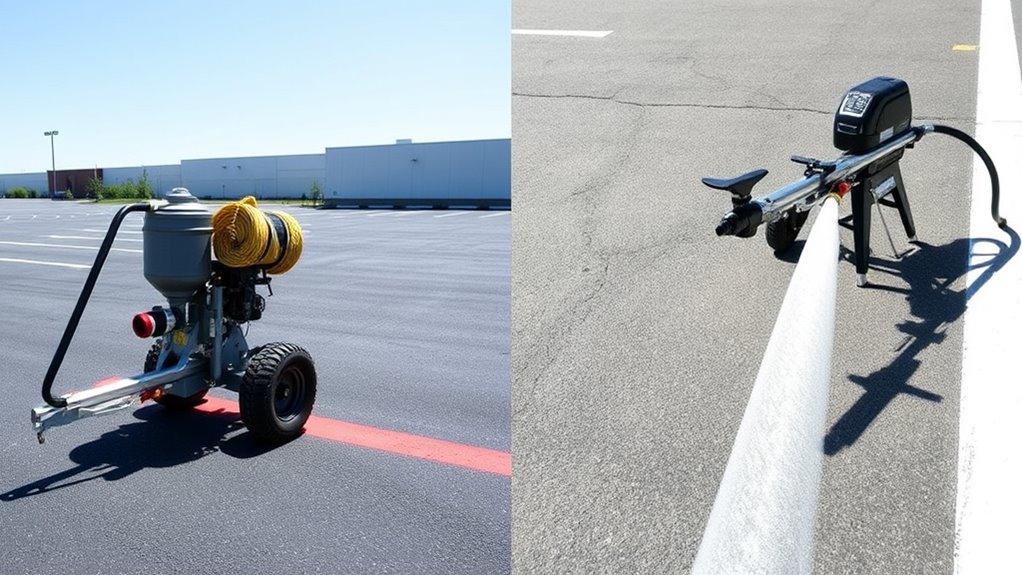

- Parking lot sprayers are designed for large-scale, high-volume application, while paint sprayers often target smaller or detailed projects.

- Airless line stripers use specialized nozzles and adjustable spray widths for precise pavement markings, unlike general paint sprayers.

- Parking lot sprayers operate at higher pressures to produce consistent, sharp lines suitable for safety and regulatory standards.

- Line stripers are built with durable, corrosion-resistant materials for outdoor, heavy-traffic environments, unlike many indoor or lightweight paint sprayers.

- They typically feature large-capacity tanks and advanced controls for efficiency over extensive areas, differentiating them from smaller, portable paint sprayers.

Design and Construction of the Equipment

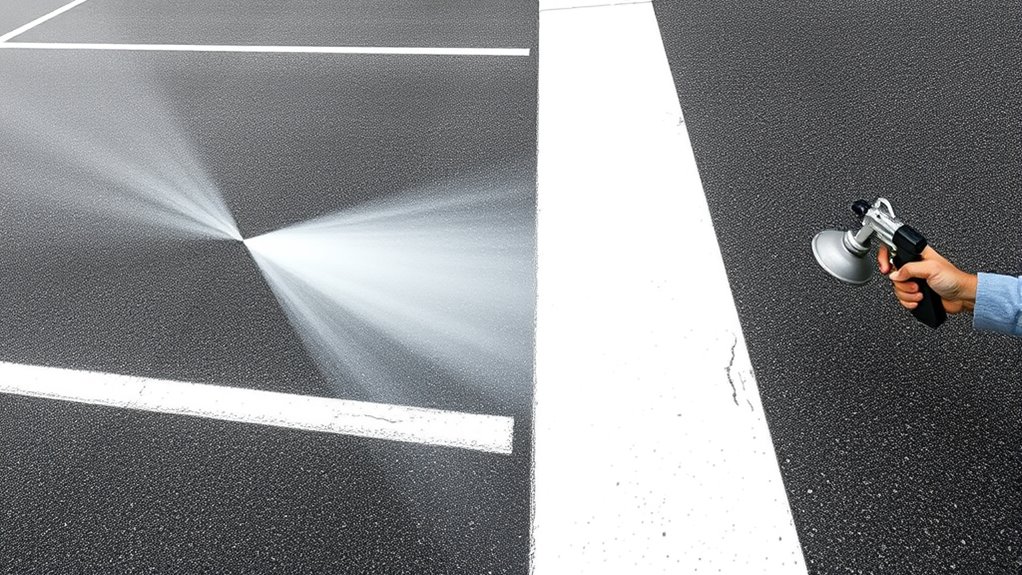

The design and construction of airless line stripers focus on creating efficient, durable equipment that delivers precise lines with minimal effort. A key component is the pump mechanism, which generates high pressure to force paint through the system consistently. This ensures even flow and sharp lines regardless of surface or conditions. The nozzle design; it’s tailored to produce a clean, uniform spray pattern, reducing overspray and paint waste. The nozzles are often adjustable, allowing you to control line width easily. Materials used in construction are sturdy, resisting wear and corrosion from frequent use. Overall, these design features work together to provide reliable, accurate results, making your line striping process faster and more consistent. High performance components are essential to maintain accuracy and efficiency over time.

Application Techniques and Methods

To achieve clean, sharp lines with airless line stripers, mastering proper application techniques is essential. Start by maintaining consistent pressure and a steady pace to ensure even paint distribution. Focus on color matching; choose high-quality paints that match your existing markings for a seamless look. Be mindful of the environmental impact by using eco-friendly paints and minimizing overspray. Proper nozzle selection and spray angle improve accuracy. Keep equipment clean to prevent clogs. Here’s a quick reference:

| Technique | Purpose | Tips |

|---|---|---|

| Consistent Speed | Sharp edges and smooth lines | Practice steady movement |

| Correct Nozzle Size | Precise line width | Use manufacturer recommendations |

| Overlap Passes | Avoid gaps and uneven edges | Slightly overlap previous lines |

| Proper Paint Mix | Color matching and flow control | Stir thoroughly before application |

Maintaining proper technique not only enhances the quality of the lines but also reduces paint waste and environmental impact. Effective techniques ensure professional results and reduce environmental impact.

Coverage Area and Speed

Maximizing coverage area and controlling speed are key to efficient line striping. To do this, you need to consider paint viscosity, which affects how much paint is applied per pass and how smoothly it flows through the spray tip. A paint with the right viscosity produces a consistent spray pattern, ensuring even coverage without drips or gaps. Adjusting your speed helps balance coverage and quality; moving too fast might lead to thin lines, while going too slow wastes time and material. By finding the ideal combination of paint viscosity and spray pattern, you can increase your coverage area without sacrificing line clarity. Proper control of speed and paint flow ensures a professional finish and efficient use of your equipment. Additionally, understanding industry trends can help you stay updated on new equipment and techniques that improve efficiency.

Precision and Line Quality

Achieving precise lines with a professional appearance depends on more than just coverage and speed; it requires careful control over spray technique and equipment adjustments. With airless line stripers, consistent pressure and steady hand movements are key to creating clean, sharp lines that enhance your branding strategies. Proper nozzle selection and spray angle help prevent overspray and uneven edges, ensuring your markings look professional and durable. Additionally, the precision of your spray impacts the environmental impact by reducing waste and limiting overspray. By fine-tuning your equipment and technique, you’ll produce high-quality lines that reinforce your brand’s image while supporting eco-friendly practices. Clear, well-defined lines not only improve safety but also demonstrate your commitment to quality and environmental responsibility. Optimal spray control is essential for achieving the best results in line striping projects.

Types of Paint and Materials Used

Choosing the right type of paint and materials is vital for making sure your line striping projects are durable and professional-looking. You need to consider the paint chemical properties to guarantee they’re compatible with your airless sprayer and surface. Traffic paint, thermoplastic, and water-based latex are common options, each with different chemical compositions suited for specific applications. Material compatibility is essential; using incompatible paints can cause clogs, inconsistent lines, or paint failure. Always check the manufacturer’s recommendations for your equipment and surfaces. Selecting the proper materials ensures smooth application, vibrant color, and long-lasting results. By paying attention to paint chemical formulations and compatibility, you’ll achieve cleaner lines and a more professional finish that withstands traffic and weather conditions. Additionally, understanding the paint compatibility with natural materials like wood, stone, or linen can help prevent surface damage and ensure longevity.

Maintenance and Durability

Regular maintenance is essential to guarantee your line striping remains durable and maintains a professional appearance over time. Keep your airless sprayer clean and check for clogs to prevent paint buildup that can affect performance. Properly maintaining your equipment also improves fuel efficiency, helping you save on operating costs. Additionally, regular tune-ups can reduce noise levels, making your work environment more comfortable and less disruptive. Lubricate moving parts and inspect hoses and seals to prevent leaks and breakdowns. Well-maintained equipment lasts longer, performs better, and ensures consistent results. Staying on top of maintenance not only extends the life of your sprayer but also maximizes efficiency, saving you time and money while delivering high-quality striping every time. Incorporating industry transformations into your maintenance routine can also help adapt to emerging technologies and stay competitive in your field.

Cost and Investment Considerations

Investing in an airless line striping system requires careful consideration of both upfront costs and ongoing expenses. You should do a thorough pricing comparison between purchasing equipment and renting. Buying may involve a significant initial investment but offers long-term savings if you plan regular striping jobs. Rental costs, on the other hand, can be more manageable for short-term projects or occasional use, reducing your immediate cash outlay. Keep in mind that rental fees often include maintenance and support, which can lower your operational costs. Additionally, consider the durability and lifespan of the equipment, as well as the potential for repairs or replacements. Balancing these factors helps you make an informed decision that aligns with your budget and project demands. Moreover, understanding the risks involved in merchant services such as security vulnerabilities and regulatory compliance can help you safeguard your investment in equipment and ensure smooth transactions.

Suitable Projects and Use Cases

Airless line stripers are ideal for a variety of projects that demand quick, clean, and durable markings. If you need to create parking lot markings that meet line striping standards, an airless sprayer can deliver professional results efficiently. They excel in large-scale projects like parking lot lines, crosswalks, and fire lanes, providing sharp, consistent lines that withstand heavy traffic and weather. These sprayers are perfect when speed and precision matter, reducing project time compared to traditional brushes or air paint sprayers. Whether you’re updating existing markings or creating new layouts, an airless line striper ensures your work adheres to safety and regulatory standards. For contractors and property managers, they’re a reliable choice for high-quality, long-lasting markings. Recognizing the importance of angel number symbolism can also inspire confidence in your project planning and execution.

Frequently Asked Questions

How Do Environmental Conditions Affect Sprayer Performance?

Environmental conditions can considerably impact sprayer performance. Humidity impact affects how paint or sealant dries, so high humidity may cause longer drying times or uneven application. Temperature considerations are essential; if it’s too cold, the material may not flow properly, while excessive heat can cause rapid drying and clogs. You need to monitor both humidity and temperature to guarantee smooth, consistent results and prevent spray issues.

What Safety Precautions Are Necessary During Operation?

Imagine working with a powerful sprayer, where safety is your shield. You need to wear personal protective gear like gloves, goggles, and masks to guard against fumes and splatters. Always keep an emergency shutdown accessible in case of unexpected issues. Staying vigilant and prepared minimizes risks, ensuring you operate the equipment safely while protecting yourself from potential hazards. Safety isn’t just a rule; it’s your top priority.

How Do Maintenance Routines Differ Between Parking Lot and Paint Sprayers?

You need to focus on different maintenance routines based on the equipment. For parking lot sprayers, regularly check and calibrate the equipment to guarantee consistent line quality, and ensure operator training emphasizes proper calibration procedures. In contrast, paint sprayers require more frequent cleaning and inspection of filters and seals. Both demand routine maintenance, but parking lot sprayers emphasize calibration and operator expertise, while paint sprayers prioritize cleaning and replacing worn parts.

Can Equipment Be Customized for Specific Project Requirements?

You can definitely customize equipment for specific project requirements, thanks to various customization options. Equipment adaptability allows you to tailor sprayers to different surfaces, materials, and spray patterns. By choosing the right nozzles, pressure settings, and accessories, you guarantee ideal performance for your job. This flexibility helps you achieve precise results, reduces waste, and improves efficiency, making your equipment a perfect fit for each unique project.

What Are the Latest Technological Advancements in Airless Line Stripers?

You’ll find that the latest airless line striper advancements boost performance with improved sprayer ergonomics, making operation more comfortable and reducing fatigue. New color matching techniques guarantee precise, consistent lines, saving time and reducing errors. These innovations help you work more efficiently and deliver professional results, whether you’re lining parking lots or creating intricate designs. Staying updated on these advancements allows you to choose equipment that enhances productivity and quality in your projects.

Conclusion

Choosing between parking lot sprayers and paint sprayers is like selecting the right brush for your masterpiece—you want tools that fit your needs perfectly. By understanding their differences in design, application, and cost, you can make an informed decision that guarantees your lines are sharp and durable. When you pick the right equipment, you’re not just marking pavement—you’re painting a picture that lasts. So, gear up and make your markings stand out like a beacon on a dark night.