Lubricating the moving parts of your airless paint sprayer is essential for peak performance and longevity. You should use specific lubricants, like Fusion Quick-Shot Gun Grease, to maintain o-rings and seals. Make it a daily routine to grease these components and guarantee effective grease distribution by purging air from the system. Always clean the manifold sealing faces before applying grease to prevent buildup and operational issues. By consistently following a lubrication protocol, you can minimize unexpected downtime and maintain efficiency. There are even more techniques and tips that'll enhance your maintenance regimen for better performance.

Key Takeaways

- Incorporate daily lubrication using Fusion Quick-Shot Gun Grease for moving parts and o-rings to ensure optimal performance.

- Clean fluid manifold sealing faces with a compatible solvent before applying grease to avoid contamination.

- Purge air from the system to ensure effective grease circulation during lubrication.

- Regularly lubricate threads and seals during rebuilds to maintain functionality and prevent leaks.

- Tailor lubrication techniques to specific gun models for enhanced longevity and efficiency.

Importance of Regular Lubrication

Regular lubrication is vital for keeping your airless paint sprayer running smoothly. By applying the right gun lube regularly, you minimize maintenance costs and unexpected downtime. When you grease the moving parts and seals properly, you greatly prolong the lifespan of your spray equipment, preventing premature repairs and failures.

Regular maintenance and cleaning tips are important for guaranteeing ideal performance and longevity of your sprayer, as mentioned in maintenance and cleaning tips.

You should make it a habit to apply lubricants like Fusion Quick-Shot Gun Grease daily. This practice helps maintain the integrity of o-rings and seals, ensuring that everything operates at peak efficiency. Neglecting lubrication, on the other hand, can lead to overspray buildup, making disassembly difficult and increasing the risk of operational issues.

Always opt for manufacturer-specific lubricants, such as TSL or Titan Piston Lube, to assure compatibility with your equipment. Using unsuitable oils can cause damage that may not be immediately apparent but could lead to costly repairs down the line.

Selecting the Right Grease

When it comes to selecting the right grease for your airless paint sprayer, understanding the various types is essential.

Choosing a lubricant that caters to the specific needs of your equipment can greatly enhance its performance, much like the importance of HVAC maintenance in guaranteeing a comfortable environment.

You'll want to apply the right lubrication techniques and confirm compatibility with your equipment to avoid any damage.

Let's explore these vital points to keep your sprayer in top shape.

Grease Types Overview

Selecting the right grease for your airless paint sprayer is essential for maintaining ideal performance and prolonging its lifespan. Understanding the different grease types can help you make informed choices. Regular maintenance, much like general air purifier usage, is critical to guarantee optimal functionality.

One popular option is Fusion Lubrication Gun Grease, which is lithium-based and designed specifically for lubricating moving parts and o-rings. This type of grease guarantees optimal performance and longevity of your spray gun.

On the other hand, Fusion Quick-Shot Gun Grease is petroleum-based and recommended for end-of-day maintenance. It offers high adhesion and water-resistant properties, making it suitable for all types of spray guns.

However, it's essential to avoid using petroleum or vegetable-based lubricants in certain cartridges, as they can lead to tool failure and decreased performance. Regular greasing with the appropriate type of grease not only minimizes maintenance costs but also reduces unexpected downtime, extending the lifespan of your equipment.

Properly lubricating o-rings, seals, and threads with the correct grease during rebuilds and daily maintenance is critical. By selecting the right grease types, you'll guarantee your airless paint sprayer operates reliably and efficiently.

Application Techniques

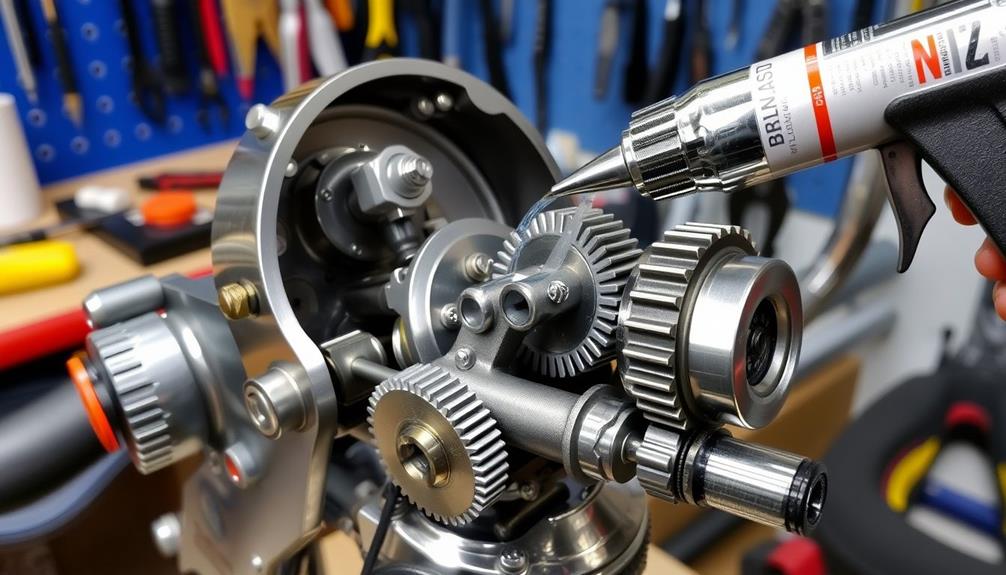

Understanding how to apply grease effectively is essential to keeping your airless paint sprayer in top shape. For regular maintenance, you should use Fusion Lubrication Gun Grease. This lithium-based grease is specifically formulated for peak performance in spray guns, particularly around the gun head and other moving parts.

Additionally, using the correct oil for your sprayer is vital, as it guarantees peak performance and longevity, while reducing wear and tear on internal components correct oil selection.

At the end of each day, apply Fusion Quick-Shot Gun Grease. This petroleum-based option offers high adhesion and water-resistant properties, making it suitable for all spray guns.

During your maintenance routine, avoid petroleum or vegetable-based lubricants for specific cartridges, as they can cause damage and reduce the lifespan of your equipment.

When lubricating, focus on important components like o-rings, seals, and threads. Confirming these parts are well-greased will help maintain the functionality and efficiency of your sprayer.

Don't forget to purge air through the gun to carry grease mist into internal components. This step guarantees thorough lubrication and prevents overspray buildup, enhancing the overall performance of your airless paint sprayer.

Compatibility Considerations

Your airless paint sprayer's performance hinges on using the right grease for its specific components. For superior results, you should use lithium-based Fusion Lubrication Gun Grease for lubricating moving parts and o-rings in your spray gun. This type of grease enhances both performance and longevity, keeping your equipment running smoothly.

Additionally, incorporating diversification of retirement portfolio into your financial strategy can be akin to confirming your tools are well-maintained; both approaches aim to minimize risks and maximize efficiency.

For end-of-day maintenance, Fusion Quick-Shot Gun Grease is an effective, petroleum-based option. However, be cautious: it's not suitable for cartridges that need a non-petroleum lubricant. Always check your manufacturer's manual to verify you're using a compatible solvent for your specific gun model.

Regularly greasing seals, threads, and moving parts with the appropriate grease prevents overspray buildup and makes disassembly easier during maintenance.

Avoid petroleum or vegetable-based lubricants entirely, as they can lead to tool failure and degrade your spray gun's functionality. By selecting the right grease and following these guidelines, you can guarantee that your airless paint sprayer operates at peak efficiency, prolonging its lifespan and improving your painting projects.

Step-by-Step Greasing Procedures

To keep your airless paint sprayer running smoothly, you'll want to establish a daily lubrication routine.

This includes applying grease specifically formulated for your gun to protect and maintain its moving parts.

Regular maintenance, similar to understanding home cleaning service costs, can save you money in the long run.

Daily Lubrication Routine

While maintaining your airless paint sprayer, incorporating a daily lubrication routine is essential for peak performance. Start by using Fusion Quick-Shot Gun Grease to keep the moving parts and o-rings in top shape. Follow these steps for effective greasing:

| Step | Action |

|---|---|

| 1. Purge Air | Remove air from the system to guarantee grease circulates effectively. |

| 2. Clean Manifold | Use a compatible solvent to clean the fluid manifold sealing faces. |

| 3. Apply Grease | Coat exposed surfaces, o-rings, seals, and threads with grease. |

Gun-Specific Greasing Techniques

Maintaining the longevity and performance of your airless paint sprayer involves specific greasing techniques tailored to each gun model.

Keeping your tools in top shape is vital, much like guaranteeing a serene atmosphere in a Modern Farmhouse Bedroom.

For the Fusion CS Gun, start by lubricating the o-rings and seals regularly. Apply Fusion Quick-Shot Gun Grease daily to guarantee peak performance.

The Fusion AP Gun follows similar greasing practices; daily grease application is important to keep moving parts functioning smoothly.

When it comes to the Fusion PC Gun, don't skip regular lubrication of o-rings and seals. Again, daily greasing is recommended to prevent wear and confirm that everything operates without a hitch.

The Probler P2 Gun requires the same protocols as the CS and AP models, emphasizing the necessity of daily lubrication for reliable functionality.

Gun-Specific Maintenance Tips

Taking care of your spray gun is important for peak performance and longevity. Each model has specific maintenance needs to keep it running smoothly. Here are some key tips for various spray guns:

| Spray Gun Model | Maintenance Tip | Frequency |

|---|---|---|

| Fusion CS, AP, PC | Lubricate o-rings and seals with Quick-Shot | Regularly |

| Probler P2 | Daily greasing with Quick-Shot is essential | Daily |

| Fusion MP | Apply Quick-Shot to moving parts to minimize costs | Daily |

| All Models | Lubricate threads and seals during rebuilds | When rebuilding |

| All Models | Clean sealing faces with solvent and grease them | Regularly |

Before you apply grease, always purge air from the system to guarantee the lubricant reaches all internal components. This step is crucial for maintaining effective operation. Additionally, protecting the fluid manifold sealing faces with grease helps guard against moisture, which is important for all gun models. Following these gun-specific maintenance tips will help extend the life and efficiency of your spray gun.

Cleaning Protocols for Longevity

Proper maintenance of your spray gun sets the stage for effective cleaning protocols, which are essential for ensuring longevity. Just like how garage door openers enhance home security with modern technology, a well-maintained airless paint sprayer will perform efficiently and effectively.

After each use, you should thoroughly clean your airless paint sprayer by removing heavy paint from the gun and cup. Follow this by applying 3 to 4 oz. of a compatible solvent for internal cleaning. Percolate the spray gun with low pressure—5 psi or less—and repeat the cleaning process until the solvent runs clear. This step is vital for eliminating all residual paint and debris.

Next, wipe the exterior of the spray gun with solvent and blow-dry it. Once dry, it's essential to apply lubricant to all moving parts, as this helps maintain performance and prevents wear.

Remember to avoid submerging the spray gun in cleaning solutions unless you're performing a complete overhaul, which can damage internal components. Regularly inspect the air cap, soaking it in a compatible cleaning solution. Use soft tools like wooden toothpicks to clean orifices without causing damage.

Performance Insights and User Feedback

User experiences highlight that diligent maintenance practices, including regular lubrication and thorough cleaning, greatly boost the performance of airless paint sprayers. Many users report that meticulous lubrication directly enhances their sprayer's efficiency, leading to smoother application and fewer operational issues.

For instance, initial trials with cabinet paint showed that proper lubrication allowed sprayers to function without needing to thin the paint, streamlining the painting process. Additionally, effective keyword and content strategy can provide insights into ideal maintenance practices, helping users maximize their equipment's performance.

Feedback consistently points out that neglecting recommended lubrication practices can lead to tool failure and decreased performance. This underscores the essential nature of maintenance. While users often express satisfaction with their sprayer's performance on small projects, they also note limitations during larger tasks, emphasizing the need to follow maintenance guidelines for best results.

Community insights reveal that consistent lubrication, especially of the throat seal and moving parts, is crucial for extending the sprayer's lifespan and ensuring reliable operation. By prioritizing lubrication, you can avoid common pitfalls and enjoy a more effective painting experience.

Ultimately, investing time in proper maintenance will pay off, allowing you to tackle any project with confidence and ease.

Safety Precautions During Maintenance

Before diving into maintenance tasks, it's important to prioritize safety to prevent accidents and injuries. Start by always disengaging the trigger lock and aiming the sprayer away from people. This simple step can prevent accidental discharges that could cause harm.

Additionally, ensuring that your workspace is well-lit and organized can help you avoid mishaps while working on the sprayer, as proper visibility reduces the risk of accidents. Remember that using a reliable home security system can also enhance your safety by deterring potential intruders while you focus on your maintenance tasks.

Next, inspect the hoses for any signs of damage. Even minor flaws can lead to dangerous high-pressure leaks, so don't skip this critical precaution.

While working, avoid increasing pressure unnecessarily; maintaining consistent pressure levels is important for safety.

Ensure all attachments are securely fastened before you perform any work on the sprayer. Loose attachments can result in leaks or accidents that put you at risk.

Troubleshooting Common Issues

Airless paint sprayers can sometimes throw you a curveball with issues like spitting or inconsistent spray patterns. When this happens, the first step is to check for clogs in the filter or any air supply issues. It's often best to address these minor problems before considering a complete disassembly of the sprayer.

Regularly lubricating all moving parts of your spray gun with the right lubricant helps prevent wear and keeps everything running smoothly.

If you notice your sprayer isn't building pressure, inspect the seals and packing for any signs of wear. These components are essential for proper operation, and neglecting them can lead to bigger issues down the line.

When troubleshooting, keep track of any problems and their occurrences; this can help identify patterns that might reveal underlying issues more effectively.

Also, verify that all cleaning solutions you use during maintenance are compatible with your sprayer's materials. Using incompatible products could cause damage and result in malfunctions.

Frequently Asked Questions

How to Lube an Airless Paint Sprayer?

To lube an airless paint sprayer, you'll want to apply TSL to the throat seal, use compatible lubricant on moving parts, and regularly grease o-rings and seals for best performance and longevity.

What Places Need to Be Lubricated on a Spray Gun?

Your spray gun's like a well-oiled machine; it needs lubrication in the o-rings, seals, piston throat, trigger mechanisms, and fluid manifold threads. Regular greasing keeps it running smoothly and extends its lifespan dramatically.

What Kind of Oil Do You Use in an Airless Sprayer?

You should use manufacturer-specific lubricants like TSL or Titan Piston Lube in your airless sprayer. Avoid motor oil, as it can damage your sprayer's performance. Always check the guidelines for the right lubricant.

How Do You Lubricate a Spray Gun?

A well-oiled machine runs smoothly. To lubricate your spray gun, apply a suitable lubricant to all moving parts after cleaning, ensuring everything's greased up, especially o-rings and seals, for peak performance and longevity.

Conclusion

So, there you have it—maintaining your airless paint sprayer isn't rocket science, but it sure can feel like it when you're knee-deep in grease. Just remember, a well-lubricated sprayer is like a happy puppy; it works better and doesn't leave a mess everywhere. If you ignore the maintenance, you might as well start a new hobby: wall art from splattered paint! Keep your sprayer in tip-top shape, and it'll thank you with smooth, flawless finishes.