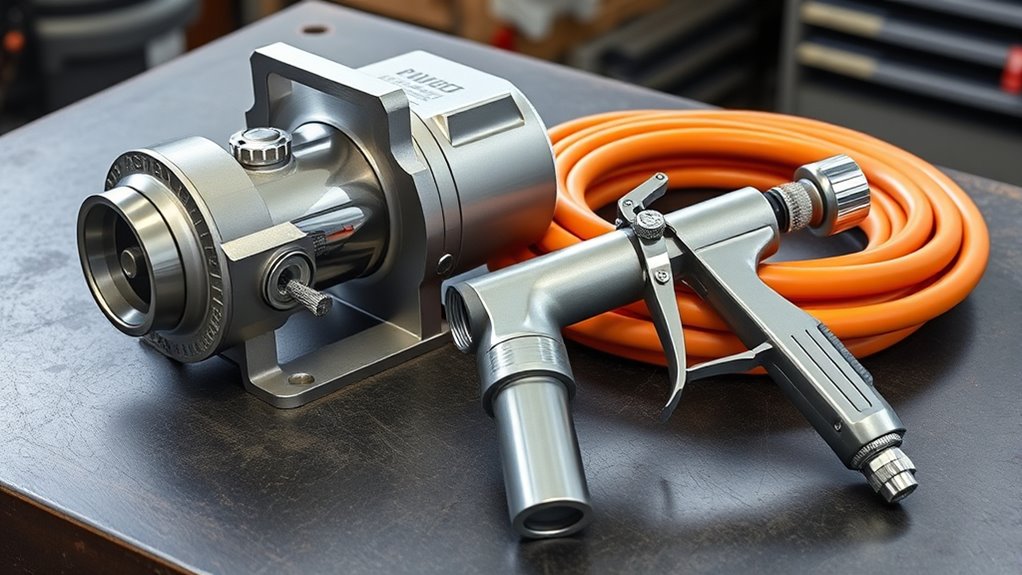

The key components of an airless sprayer system include the pump, which pressurizes the paint; the hose, connecting the pump to the spray gun and guaranteeing consistent flow; and the spray gun itself, atomizing the paint into fine droplets for a smooth finish. You also need to assess paint viscosity and proper system integration for ideal results. Keeping these parts working together ensures a flawless application, and exploring each element helps you master the system more effectively.

Key Takeaways

- Pump pressurizes paint for high-velocity delivery and consistent spray patterns.

- Hose serves as the durable conduit between the pump and spray gun, affecting flow and pressure.

- Spray gun atomizes paint, with nozzle size and shape controlling spray pattern and coverage.

- Paint must be compatible with system pressure and viscosity for optimal atomization and finish.

- Proper system integration and adjustments ensure even coverage and high-quality painting results.

An airless sprayer system is made up of several essential components that work together to deliver a smooth, even spray. One of the most critical parts is the pump, which pressurizes the paint and pushes it through the system at high velocity. The pump’s pressure settings directly influence the paint viscosity you can work with; thicker paints require higher pressure to atomize properly. If the pressure isn’t set correctly, the spray pattern can become uneven, resulting in drips or missed spots. You’ll want to adjust the pressure based on the type of coating and the desired finish, ensuring a consistent spray pattern that covers surfaces uniformly.

Next, the hose connects the pump to the spray gun, serving as the conduit that carries the pressurized paint. Its diameter and length impact the overall spray quality. A wider hose allows for a higher flow rate, which helps maintain a steady spray pattern, especially when working on large surfaces. Conversely, longer hoses can cause a slight pressure drop, so you might need to increase the pump’s pressure to compensate. The hose’s material must withstand high pressure and prevent paint clogging, ensuring your spray pattern remains consistent throughout the job.

A wider, durable hose maintains consistent spray quality and prevents clogging during large projects.

The spray gun is where the magic happens. It’s designed to atomize the paint, breaking it into tiny droplets for a smooth finish. The gun’s nozzle plays a vital role in shaping the spray pattern, determining whether it’s wide, narrow, or fan-shaped. Adjusting the nozzle size allows you to control the spray pattern to suit different surfaces and coverage needs. When working with paints of varying viscosity, you should select a nozzle that can handle the thickness without clogging, maintaining a steady, even spray. Proper handling of the spray gun helps you keep the spray pattern uniform, avoiding over-application or uneven coverage.

Finally, the paint itself must be compatible with your system’s pressure and nozzle specifications. Paint viscosity affects how well it atomizes and influences the spray pattern. Thicker paints may require thinning to flow smoothly through the system, ensuring a uniform spray. If the paint is too viscous, it can clog the nozzle and distort the spray pattern, leading to an inconsistent finish. Regularly checking and adjusting the viscosity ensures the system functions optimally, providing an even, professional-looking coating every time. Understanding how pressure and viscosity interact is crucial for achieving high-quality results.

All these components—pump, hose, spray gun, and paint—must work in harmony. Properly managing paint viscosity and understanding how it impacts the spray pattern is key to achieving high-quality results. When each part functions correctly and is adjusted to suit your specific project, you’ll enjoy a seamless spraying experience with a flawless, even finish.

Frequently Asked Questions

How Often Should I Clean My Airless Sprayer System?

You should clean your airless sprayer system after every use to guarantee peak performance and prevent clogs. Following a regular maintenance schedule, cleaning thoroughly after each project, will extend your equipment’s lifespan. If you’re switching between different paints or coatings, cleaning becomes even more critical. Neglecting cleaning can lead to paint buildup, reduced spray quality, and costly repairs, so make it a priority in your maintenance routine.

Can I Use My Airless Sprayer for Latex and Oil-Based Paints?

Using your airless sprayer for both latex and oil-based paints is possible, but you need to consider paint compatibility and sprayer adjustments. I once switched from latex to oil-based paints without cleaning thoroughly, and it clogged my nozzle. Make sure you clean your sprayer thoroughly between uses and adjust the pressure settings accordingly. Check your sprayer’s manual for specific recommendations on paint compatibility to get the best results.

What Safety Precautions Are Necessary When Operating an Airless Sprayer?

When operating an airless sprayer, you must prioritize safety. Wear protective gear like goggles, gloves, and a mask to prevent paint fumes and splatters. Make certain of proper ventilation safety by working in a well-ventilated area to avoid inhaling harmful fumes. Always read the manufacturer’s instructions, check for leaks, and keep the sprayer on a stable surface. Taking these precautions protects you and guarantees a smooth, safe painting experience.

How Do I Troubleshoot Pressure Issues in My Sprayer System?

When troubleshooting pressure issues, start by checking for pressure fluctuations and hose kinks. You can improve performance by ensuring the pressure regulator is set correctly, inspecting the hose for any bends or blockages, and cleaning the filters to prevent clogs. Also, verify that the pump is functioning properly and look for leaks. Addressing these areas helps maintain consistent pressure and smooth spraying.

Is There a Recommended Maintenance Schedule for Airless Sprayer Components?

You should follow a regular maintenance checklist to keep your airless sprayer in top shape. Inspect and clean components like the nozzle, filters, and hoses after each use. Replace parts as needed based on their component lifespan, typically every few years or when showing signs of wear. Regularly lubricate moving parts and check for leaks. This routine helps prevent issues and extends your sprayer’s performance and durability.

Conclusion

Now that you know the key components of an airless sprayer system, you’re like a skilled conductor ready to orchestrate a flawless painting symphony. Each part, from the pump to the spray tip, works together like a well-tuned instrument, creating a masterpiece with every stroke. With this knowledge in hand, you’ll wield your sprayer confidently, transforming dull surfaces into vibrant works of art—turning every project into a beautiful, seamless melody.