Airless sprayers use a high-pressure pump to atomize paint without compressed air, making them ideal for large surfaces like exteriors and fences, offering quick, smooth coverage. Air spray guns rely on compressed air to create fine droplets, perfect for detailed work such as furniture or trim. While airless sprayers are faster and produce a more uniform finish, spray guns provide greater precision. To discover which tool suits your project best, explore the key differences further.

Key Takeaways

- Airless sprayers deliver faster, more uniform coverage suitable for large surfaces, while spray guns excel in detailed, precision work.

- Airless systems produce less overspray and airborne particles, making them more environmentally friendly compared to spray guns.

- Spray guns allow greater control over spray pattern and are ideal for fine finishes and intricate projects.

- Airless sprayers are generally larger, heavier, and less portable but offer higher efficiency for big jobs; spray guns are lightweight and portable.

- Maintenance for airless sprayers is more complex, involving disassembly and cleaning of multiple parts, whereas spray guns have simpler cleaning routines.

Defining Airless Sprayers and Air Spray Guns

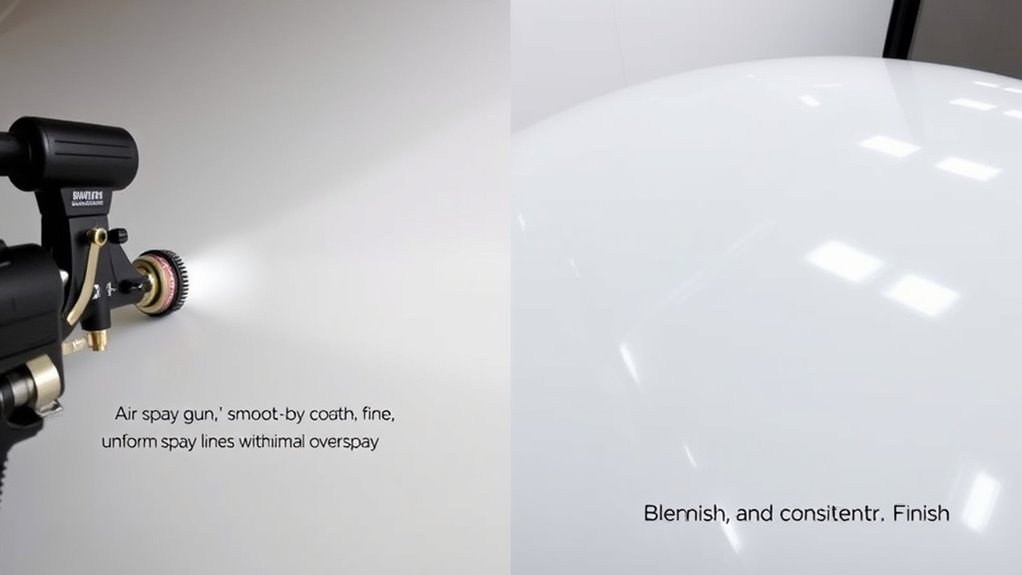

Airless sprayers and air spray guns are two common tools used for applying paint and coatings, but they operate quite differently. An airless sprayer works by forcing paint through a high-pressure pump, atomizing the paint without using compressed air. In contrast, an air spray gun uses compressed air to break the paint into fine droplets. When it comes to paint mixing, airless sprayers typically handle thicker materials directly, while spray guns often require more precise paint thinning. The spray nozzle design also varies: airless sprayers have a simple, wide nozzle for larger coverage, whereas air spray guns feature smaller, adjustable nozzles for detailed work. Understanding these differences helps you choose the right tool for your project needs. Additionally, air quality features such as HEPA filtration and UV light technology in air purifiers ensure cleaner indoor environments, which can be beneficial during painting projects. Selecting the appropriate tool can also depend on factors like application type, which influences the level of detail and coverage required for your project. Knowing the applications of each tool can further assist in selecting the best equipment for specific projects, especially considering the performance and efficiency differences highlighted in expert reviews.

Key Features and Operating Mechanisms

Understanding the key features and operating mechanisms of these tools is essential for choosing the right one for your project. With airless sprayers, the sprayer nozzle design is vital, as it determines spray pattern and atomization quality. These nozzles are typically designed for high pressure, providing a consistent, even coating. Paint flow regulation in airless sprayers is controlled by a pressure control valve, allowing you to adjust the flow rate for different surfaces and materials. Conversely, air spray guns rely on compressed air to atomize paint, with their nozzles customizing spray patterns and sizes. Proper paint flow regulation in spray guns is achieved through adjustable knobs, giving you precise control. Understanding these features helps you select the tool that best matches your project’s demands for efficiency and finish quality. Additionally, the industry transformations driven by automation and innovation emphasize the importance of selecting the right equipment to stay competitive. Incorporating advanced technology in spray equipment can further enhance application precision and reduce waste, aligning with modern industry standards. For instance, modern airless sprayers often feature digital controls that allow for more accurate adjustments and monitoring during operation. Moreover, understanding the maintenance requirements of each tool is crucial for ensuring longevity and optimal performance. Staying updated on emerging trends in spray technology can help you adapt to evolving project needs and improve overall results.

Suitability for Different Types of Projects

Choosing between airless sprayers and air spray guns depends largely on the scale and detail of your project. For large surfaces like exteriors or fences, airless sprayers excel because they deliver fast, uniform coverage with minimal surface preparation. They’re ideal for projects where speed and efficiency matter most. Conversely, air spray guns are better suited for detailed work, such as furniture or trim, where precision and control are essential. They often require more surface preparation to achieve a smooth finish. Additionally, consider environmental impact: airless sprayers typically produce less overspray, reducing waste, while air spray guns can generate more airborne particles. An understanding of appropriate equipment can also help in selecting the right tools for different projects, as certain techniques may be more effective depending on the surface and finish desired. Your choice ultimately hinges on project size, detail level, and environmental considerations. For example, understanding spray technique can significantly influence the quality of your finish and efficiency. Moreover, being aware of emission control practices can help minimize environmental impact during spraying.

Application Speed and Coverage Efficiency

When it comes to application speed and coverage efficiency, airless sprayers generally outperform air spray guns, especially on large surfaces. They deliver a higher application speed, allowing you to cover more area in less time. Their design provides uniform coverage, reducing overspray and ensuring a smoother finish. Here’s what makes them stand out:

- Faster coverage, saving you time on big projects

- Consistent spray pattern enhances coverage efficiency

- Less need for multiple coats due to even application

- Reduced operator fatigue thanks to efficient flow rates

- Sprayer Pressure can be adjusted to optimize spray settings for different painting projects. Additionally, understanding performance upgrades can help improve the overall efficiency and capability of your equipment, similar to how tuning modifications enhance vehicle performance. Incorporating energy monitoring features in your sprayers can further optimize their operation, reducing waste and improving results. Proper maintenance also plays a vital role in maintaining peak performance and extending the lifespan of your sprayers.

Level of Finish and Surface Quality

While airless sprayers excel in covering large areas quickly, their ability to produce a smooth, high-quality finish often surpasses that of air spray guns. You’ll notice that airless sprayers tend to provide better surface smoothness, resulting in a more professional appearance. This is because they deliver a consistent, even coat with fewer overspray issues, reducing the likelihood of texture imperfections. The finish quality from an airless sprayer is typically more uniform, which means less sanding or touch-up work afterward. Additionally, spray pattern control plays a crucial role in achieving optimal surface smoothness and detail. Proper equipment settings and technique are essential for maximizing finish quality, as even minor adjustments can significantly impact the final result. For example, adjusting the pressure levels can influence atomization and spray pattern consistency. Overall, if you prioritize a superior finish, especially on large or detailed surfaces, airless sprayers generally offer a noticeable advantage. Moreover, understanding surface preparation can greatly influence the final outcome, ensuring the best possible results.

Ease of Use and User-Friendliness

Airless sprayers are generally straightforward to operate once you get the hang of them, making them a popular choice for large-scale projects. Their ergonomic design offers better comfort during prolonged use, reducing fatigue. The user interface is simple, often featuring intuitive controls that are easy to learn. To enhance your experience, consider these points:

Airless sprayers are easy to use and comfortable, making large projects less tiring.

- Adjust the spray pressure easily with minimal effort.

- Maintain a comfortable grip with ergonomic handles.

- Quickly switch between spray patterns via user-friendly controls.

- Experience less strain thanks to well-designed ergonomics, which improve comfort over long periods.

Maintenance and Cleaning Requirements

Cleaning your equipment can vary in complexity depending on whether you’re using an airless sprayer or an air spray gun. You’ll find that some models require more frequent maintenance, while others need less attention to stay in top shape. Understanding these differences helps you plan your cleaning routine effectively.

Cleaning Procedures Complexity

Maintaining your spray equipment requires attention to detail, as the cleaning process can vary considerably between airless sprayers and air spray guns. The complexity of cleaning procedures impacts your maintenance routines and overall efficiency. Airless sprayers often have more parts to disassemble and require thorough flushing to prevent clogs, making their cleaning more involved. In contrast, air spray guns generally involve simpler cleaning steps, like wiping and flushing. To keep your equipment in top shape, consider these points:

- Disassemble components carefully after each use

- Use appropriate cleaning solutions for different materials

- Regularly inspect and clean filters and nozzles

- Follow manufacturer guidelines for maintenance routines

Understanding these differences helps you maintain performance and prolong equipment lifespan.

Maintenance Frequency Differences

The frequency with which you need to perform maintenance and cleaning varies considerably between airless sprayers and air spray guns. Airless sprayers often require less frequent cleaning, which helps extend tool longevity and lengthen replacement intervals. You might clean an airless sprayer after every few uses, depending on the material and project size, reducing downtime. In contrast, air spray guns tend to need more frequent cleaning, sometimes daily, especially when switching colors or materials. Regular maintenance on air spray guns prevents clogging and wear, ensuring consistent performance. Although airless sprayers generally demand less frequent upkeep, neglecting routine maintenance can still shorten their lifespan. Overall, understanding these differences helps you optimize tool longevity and plan maintenance schedules effectively.

Cost Considerations and Budgeting

When comparing airless sprayers and air spray guns, understanding the cost implications is essential for effective budgeting. Your budget planning should consider initial investments and ongoing expenses. Here are four key points:

- Pricing strategies vary, with airless sprayers often costing more upfront but saving on labor over time.

- Maintenance costs differ; airless models might require more parts replacement, impacting long-term expenses.

- Consumables like tips and filters add to the ongoing costs, especially for high-frequency use.

- Efficiency impacts overall budget; faster coverage with airless sprayers can reduce labor costs, balancing out higher initial prices.

Portability and Storage Factors

When choosing between airless sprayers and air spray guns, consider how portable they are for your projects. You’ll want to look at their size and weight to see which is easier to carry around or transport. Don’t forget to verify their storage needs to ensure they fit comfortably in your workspace or storage area.

Size and Weight

Since portability and storage are essential factors, understanding the size and weight differences between airless sprayers and air spray guns can help you choose the right tool for your needs. Air spray guns are typically lightweight, with a compact design that makes them easy to handle and store. In contrast, airless sprayers tend to be larger and heavier due to their motor and pump components.

Here are some key points:

- Air spray guns are highly portable, ideal for quick, small projects.

- Airless sprayers, though bulkier, provide a more powerful and consistent spray.

- The compact design of spray guns simplifies storage in small spaces.

- The weight differences may impact fatigue during extended use, favoring spray guns for short tasks and sprayers for larger jobs.

Ease of Transportation

Ease of transportation plays a significant role in choosing between airless sprayers and air spray guns, especially if you frequently move between job sites or work in tight spaces. Air spray guns offer notable transportation convenience due to their lightweight and compact design, making them easy to carry and store. Their portability benefits allow you to quickly set up and pack down, saving time on the go. In contrast, airless sprayers tend to be bulkier and heavier, which can complicate transport and limit mobility. If your work requires frequent movement or working in confined areas, air spray guns provide a clear advantage. Their easy portability guarantees you can efficiently shift between jobs without hassle, giving you more flexibility and reducing setup time.

Storage Requirements

Storage requirements are a key factor to contemplate because they directly impact how easily you can keep and transport your equipment. Airless sprayers generally have larger container sizes, requiring more storage space and making them less portable. In contrast, air spray guns are compact, fitting into smaller storage areas and easier to carry around. When considering storage:

- Check if your workspace has enough room for larger equipment or containers.

- Factor in the size of the containers needed for each sprayer type.

- Consider whether the equipment can be stored vertically or needs special shelving.

- Think about the ease of access for frequent use.

Choosing the Right Tool for Your Needs

Choosing the right spraying tool depends on your specific project needs, budget, and experience level. If you’re working on detailed surfaces, brush techniques might be more suitable, but for larger areas, a sprayer is more efficient. Consider paint viscosity; thicker paints often require airless sprayers to deliver consistent coverage without clogging. Air spray guns provide a fine finish ideal for small jobs or intricate work, but they demand more skill and maintenance. If you’re new to spraying, an airless sprayer offers ease of use and speed. Conversely, if you need precision and control, especially with thinner paints, air spray guns excel. Assess your project size, desired finish, and your comfort with each tool before making a choice.

Frequently Asked Questions

Which Tool Is Better for Detailed or Intricate Painting Jobs?

For detailed or intricate painting jobs, brush precision often outperforms spray detail. You can control fine lines and delicate areas better with a brush, ensuring accuracy. While air spray guns provide smooth coverage, they might lack the finesse needed for intricate work. Airless sprayers are generally better for large surfaces, so if you want precision, a quality brush or air spray gun is your best choice for detailed projects.

How Do Airless Sprayers Handle Thick or Textured Paints?

Did you know that airless sprayers can handle thick or textured paints up to 50% better than traditional spray guns? You’ll find they excel in texture application because their high pressure easily pushes paint with varied consistency. This means you don’t need to thin your paint as much, saving time. Their powerful output guarantees even coverage on textured surfaces, making them ideal for bold, textured finishes.

Are Air Spray Guns More Environmentally Friendly Than Airless Sprayers?

You might wonder if air spray guns are more environmentally friendly than airless sprayers. Generally, air spray guns have a higher environmental impact due to increased overspray and paint waste, which also affects waste reduction efforts. Airless sprayers tend to be more efficient, minimizing paint waste and reducing VOC emissions. Choosing an airless sprayer can help you lower your environmental footprint by supporting waste reduction and lessening harmful emissions.

Can Both Tools Be Used for Outdoor Painting Projects?

Imagine transforming your outdoor space with ease—you can use either tool for outdoor painting projects. Airless sprayers cover large areas quickly, making them ideal for broad surfaces, while air spray guns excel in detailed brush techniques, perfect for intricate trim or decorative touches. Proper paint preparation guarantees smooth application, regardless of your choice. Both tools are versatile, so choose based on your project’s size and detail needs for a flawless finish.

What Safety Precautions Should I Consider for Each Tool?

When using either tool, you should prioritize safety. Always wear personal protective equipment like masks, goggles, and gloves to prevent exposure to fumes and overspray. Guarantee electrical safety by inspecting cords and plugs for damage before use. Keep the work area well-ventilated, and follow manufacturer instructions carefully. Proper maintenance and handling reduce risks, so stay alert and cautious to protect yourself during outdoor painting projects.

Conclusion

Choosing between airless sprayers and air spray guns boils down to knowing your project’s needs. If you want to get the job done quickly and efficiently, you might be tempted to bite off more than you can chew with a powerful tool. However, understanding each option’s strengths and limitations guarantees you don’t bite the hand that feeds you. Make an informed choice, and you’ll have the right tool in your corner every time.