To keep your filters and strainers performing at their best, regularly clean them to remove dirt, dust, and debris. Check for signs of clogging, tears, or corrosion, and follow manufacturer guidelines for cleaning methods such as rinsing or brushing. If cleaning isn’t enough, replace damaged parts to prevent system issues. Consistent maintenance prevents costly breakdowns and extends equipment life. Keep going to discover more tips for maintaining ideal system performance.

Key Takeaways

- Regularly inspect filters and strainers for debris buildup, damage, or corrosion to ensure optimal performance.

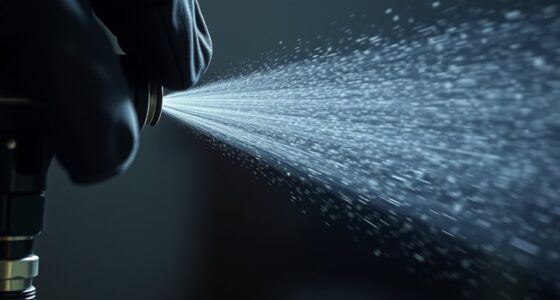

- Clean filters using manufacturer-approved methods such as rinsing with water or compressed air, avoiding damage to the media.

- Replace torn or heavily clogged filters promptly to maintain efficient fluid flow and system operation.

- Follow proper cleaning procedures by removing all dirt and debris without damaging the filter media, then dry thoroughly.

- Incorporate routine filter and strainer checks into scheduled maintenance to prevent system clogging and costly repairs.

Regularly cleaning filters and strainers is essential to guarantee your equipment runs efficiently and prevents costly breakdowns. When you perform routine filter maintenance, you help ensure that debris and contaminants don’t clog vital components, which can lead to reduced performance or even damage. Strainer inspection is a crucial part of this process; it allows you to identify any buildup or wear that could compromise the system’s operation. By staying on top of these tasks, you minimize downtime and extend the lifespan of your equipment.

Regular filter and strainer maintenance ensures system efficiency and longevity.

To start, you should establish a regular schedule for inspecting strainers. Depending on your system’s usage and the environment, this could mean weekly or monthly checks. During strainer inspection, look for signs of debris buildup, corrosion, or damage to the mesh or filtering material. If the strainer is clogged, flow rates will drop, and pressure may increase, indicating that cleaning is overdue. Clearing out accumulated debris guarantees your system maintains ideal fluid flow, which is indispensable for efficiency. When inspecting filters, pay particular attention to the condition of the filter media. Over time, filters can become clogged or develop tears that reduce their effectiveness. Replacing or cleaning the filters promptly keeps your equipment running smoothly and prevents unfiltered particles from circulating through the system.

Effective filter maintenance involves more than just cleaning; it’s about understanding when and how to do it properly. Many filters can be cleaned with water or compressed air, but some require replacement entirely. Always follow the manufacturer’s guidelines to avoid damaging the filter media. When cleaning filters, ensure you remove all dirt, dust, and debris without damaging the material. This process often involves rinsing or brushing, followed by thorough drying before reinstalling. For strainers, removal, rinsing, and inspecting the mesh are key steps. If you notice holes, tears, or corrosion, it’s time to replace the strainer to prevent future issues. Additionally, understanding the horsepower of electric dirt bikes can help you appreciate the importance of maintaining optimal system performance.

Keeping an eye on filter and strainer condition isn’t just about maintenance—it’s about proactive care. Regular inspections allow you to catch problems early, saving you money and reducing unplanned downtime. Incorporate these tasks into your routine, and you’ll maintain system efficiency and avoid unexpected failures. Remember, well-maintained filters and strainers are the backbone of reliable equipment operation, ensuring your system runs at peak performance every time.

Frequently Asked Questions

How Often Should Filters and Strainers Be Inspected?

You should inspect filters and strainers at least once a month, but the inspection frequency really depends on your maintenance schedule and the system’s usage. Regular inspections help catch clogs or damage early, preventing system downtime. If you notice debris buildup or reduced flow, increase inspection frequency. Consistently following your maintenance schedule ensures filters and strainers stay clean and perform at their best, extending their lifespan and maintaining system efficiency.

What Tools Are Recommended for Cleaning Filters?

You should use cleaning brushes to gently scrub filters and strainers, removing debris without damage. Pressure washers are excellent for rinsing out stubborn dirt and buildup quickly and thoroughly. Before cleaning, turn off the system and wear protective gear. Combining these tools guarantees your filters stay clean and functioning efficiently. Regular cleaning with brushes and pressure washers helps maintain ideal performance and extends the lifespan of your equipment.

Can Filters Be Cleaned While the System Is Operational?

You can often perform filter cleaning while the system is running, but it’s like gently tending a garden without disturbing the blooms. Some systems allow for filter cleaning without system downtime, keeping operations smooth and efficient. However, always check manufacturer guidelines first. Proper filter cleaning during operation minimizes disruption, but if there’s a risk, it’s better to schedule a brief system downtime to guarantee safety and thorough cleaning.

Are There Specific Cleaning Agents to Avoid?

You should avoid using abrasive cleaning agents and chemicals that could cause chemical incompatibilities with your filter or strainer materials. Harsh abrasives can damage delicate surfaces, reducing their effectiveness. Stick to gentle, compatible cleaning solutions recommended by the manufacturer. Always check the filter’s specifications to guarantee the cleaning agents won’t cause corrosion or deterioration, helping maintain peak performance and extending the lifespan of your system components.

How Do I Know When a Filter Needs Replacing?

You’ll know your filter needs replacing when it’s clearly overworked or showing signs of wear—like reduced flow or increased pressure. Ironically, the filter lifespan isn’t endless, despite your hopes. Replacement indicators include persistent clogs, visible damage, or if cleaning no longer restores performance. Don’t wait for total failure; proactive replacement guarantees peak system function and prevents costly breakdowns. Keep an eye on these signs for smooth operation.

Conclusion

Regularly cleaning your filters and strainers keeps your system running smoothly. For example, imagine a small manufacturing plant that ignored routine maintenance—clogged strainers caused costly downtime. By scheduling weekly cleanings, they improved efficiency and avoided surprises. Don’t wait for performance issues; stay proactive. A quick, consistent cleaning routine guarantees your equipment stays in top shape, saving you time and money in the long run. Keep those filters clear and your system working flawlessly.