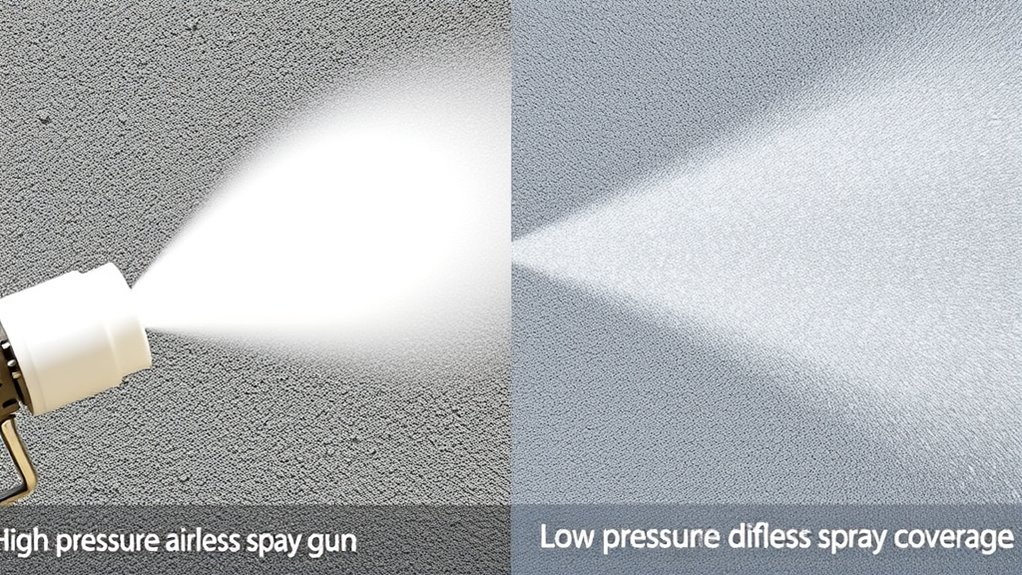

High-pressure airless sprayers are best suited for large exterior projects where you need fast coverage and thick coatings, thanks to their powerful spray and wide coverage. Low-pressure units give you more control, making them ideal for detailed interior tasks, furniture, and delicate surfaces with less overspray. To choose the right one, consider your project size and level of detail. Keep going to discover when each type makes the most sense for your work.

Key Takeaways

- High-pressure sprayers are best for large surfaces, thick coatings, and exterior projects, offering faster coverage and deeper penetration.

- Low-pressure sprayers excel in detailed, indoor work, providing better control, less overspray, and a cleaner finish.

- High-pressure systems produce a smooth, even spray suitable for rough surfaces but generate more overspray and noise.

- Low-pressure units are easier to handle, require less setup, and are ideal for small projects, furniture, and precise applications.

- Matching spray pressure to project scope ensures optimal results, efficiency, and ease of use for both large and detailed tasks.

Have you ever wondered how the pressure settings in airless paint sprayers impact your project? The pressure level you choose can make a significant difference in the quality of your finish, the speed of application, and even the ease of use. High-pressure sprayers deliver a powerful force that propels paint at a greater velocity, making them ideal for large surfaces or jobs that demand quick coverage. They can push thicker coatings and achieve a smooth, even spray on exterior walls, fences, or expansive ceilings. However, with this power comes increased overspray and paint bounce-back, which means you’ll need to be more precise to avoid waste and overspray. High-pressure systems are also typically louder and more demanding on the equipment, requiring sturdy machinery and careful handling to prevent fatigue or mishaps. Additionally, they often require more extensive setup and cleaning routines due to the higher pressure levels involved.

High-pressure sprayers offer quick coverage but require precision to manage overspray and noise.

On the other hand, low-pressure airless sprayers operate at a reduced PSI, which translates to a gentler spray and better control over the application process. If you’re working on detailed interior projects or finishing furniture and cabinetry, a low-pressure setup can give you the finesse you need. These sprayers produce less overspray, reducing mess and saving you paint. They also tend to be quieter, making them more suitable for indoor environments or areas where noise is a concern. Because the pressure is lower, you often find that they’re easier to handle, especially for DIY enthusiasts or those new to airless painting. The trade-off is that low-pressure systems may struggle with thicker paints or very large surfaces, requiring multiple coats or thinning of the paint to achieve an even finish.

Choosing between high and low pressure depends on your project’s scope and specific needs. High-pressure sprayers excel in large, rough jobs where speed and thicker coatings matter most. They cut down on time but demand more skill to control overspray and achieve a quality finish. Conversely, low-pressure units shine in detailed, smaller projects where precision and minimal overspray are critical. They offer greater control and less mess, but might not be suitable for extensive exterior applications or thick coatings without modifications. It’s also worth noting that understanding the benefits of skin hydration and nourishment provided by specific tools can influence your overall results and satisfaction.

Understanding where each pressure setting excels helps you make smarter choices. If you’re tackling a sprawling exterior wall or a fence, a high-pressure sprayer will probably serve you better. For intricate interior work or furniture refinishing, a low-pressure sprayer gives you more control and a cleaner finish. By matching the pressure to your project’s demands, you can improve your results, save time, and minimize frustration. Ultimately, knowing when to use high or low pressure helps you work smarter, not harder.

Frequently Asked Questions

How Does Pressure Affect Paint Finish Quality?

Higher pressure can create a smoother, more even paint finish because it atomizes the paint better, reducing overspray and drips. However, too much pressure might cause paint to splatter or bounce, ruining the finish. Lower pressure offers more control, ideal for delicate surfaces or detailed work, but can result in a less uniform coat if not adjusted properly. Finding the right balance guarantees a professional, high-quality finish.

Which System Is Better for Detailed or Intricate Work?

Studies show that 65% of painters prefer low-pressure systems for detailed work. You’ll find that a low-pressure airless sprayer offers more control, reducing overspray and allowing for finer detail. This system minimizes paint atomization, giving you smoother finishes on intricate surfaces. If precision matters, the low-pressure setup is your best choice, enabling you to work carefully while maintaining consistent, high-quality results on complex projects.

What Safety Precautions Are Needed for High-Pressure Systems?

When working with high-pressure systems, you need to wear protective gear like goggles, gloves, and a mask to prevent injuries from spray and debris. Always check hoses and fittings for leaks, and make certain the equipment is properly maintained. Keep your work area clear, and never point the spray gun at yourself or others. Turn off the system before cleaning or adjusting to prevent accidental discharge and injuries.

How Does Equipment Maintenance Differ Between Systems?

You need to regularly inspect and clean the equipment, replacing worn-out parts promptly. High-pressure systems require more frequent checks on hoses, seals, and valves to prevent leaks or bursts. For low-pressure systems, focus on maintaining proper fluid flow and checking for blockages. Always follow manufacturer guidelines, verify safety devices are working, and keep a detailed maintenance log to prevent failures and extend your equipment’s lifespan.

Can Both Systems Be Used for Outdoor and Indoor Projects?

Yes, you can use both systems for outdoor and indoor projects. High-pressure airless sprayers are great for large outdoor surfaces because they deliver thicker coats quickly. Low-pressure systems are ideal for indoor projects, offering finer control and reducing overspray. You just need to choose the right system based on your project’s size and detail level. Both are versatile, so select according to your specific needs to achieve the best results.

Conclusion

Ultimately, choosing between high-pressure and low-pressure airless depends on your project needs. High pressure offers faster coverage and better atomization, perfect for tough surfaces. Low pressure provides a softer finish and less overspray, ideal for delicate tasks. Remember, “A chain is only as strong as its weakest link,” so select the right pressure for your job’s success. By understanding each, you’ll guarantee your paint job is both efficient and flawless.