When comparing mobile and stationary airless systems, you’ll find that mobile units are designed for easy transport, making them ideal for small to medium projects with quick setup and greater flexibility. Stationary systems provide higher performance, precision, and are better suited for large, continuous jobs. Mobile options tend to be more budget-friendly upfront, while stationary systems often require a bigger investment but offer stability and quieter operation. Keep exploring to discover which system best fits your project needs.

Key Takeaways

- Mobile airless systems are lightweight, portable, and ideal for quick setup across various job sites, while stationary units prioritize stability and high performance for large projects.

- Mobile systems offer flexibility for small to medium tasks and are generally less expensive upfront, whereas stationary systems deliver superior spray accuracy suited for extensive, continuous work.

- Mobile units depend on batteries or portable power sources, requiring regular maintenance, while stationary systems use dedicated power supplies with easier upkeep.

- Stationary systems tend to operate quieter and with greater stability, making them suitable for noise-sensitive or large-scale environments.

- User preferences, project size, and mobility needs influence whether a mobile or stationary airless system is the best choice.

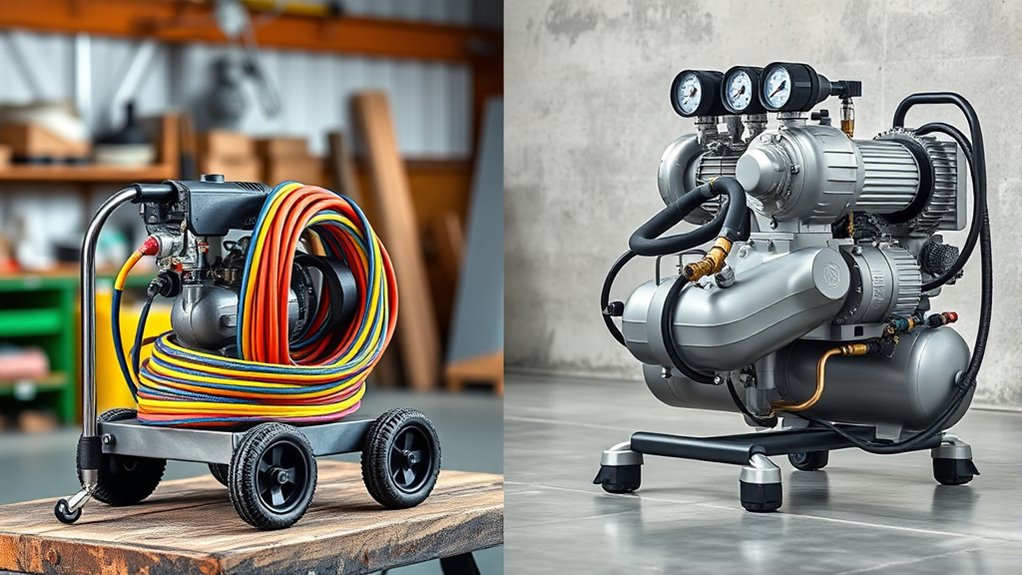

Design and Portability Features

When comparing mobile and stationary airless systems, design and portability are key factors that influence their suitability for different tasks. Mobile systems often feature ergonomic design, making them easier to handle during extended use. They come with portability features like lightweight frames, wheels, and compact sizes, allowing you to move them effortlessly around job sites. This flexibility means you can quickly reposition the equipment without much effort, saving time and reducing fatigue. Additionally, their ease of transportation makes them ideal for varied work environments and dynamic project requirements. The compact size of mobile systems enhances their ability to navigate tight spaces on job sites, further increasing their versatility. Moreover, mobile systems often incorporate energy-efficient components, which can help reduce operational costs over time. They can also be equipped with advanced features such as automatic shut-off to improve safety and efficiency during operation. Stationary systems, on the other hand, prioritize stability and often have larger, less portable designs. They’re typically fixed in one location, making them ideal for large-scale projects where mobility isn’t a priority. Your choice depends on your need for energy efficiency versus stability, with design playing a vital role in usability.

Performance and Application Scope

The performance capabilities of airless systems directly affect how well they handle various painting tasks and project sizes. Mobile systems excel in flexibility, ideal for small to medium projects, offering good spray precision and acceptable paint consistency. Additionally, understanding industry trends can help users select the most suitable system for their specific needs. For example, tuning techniques from the automotive sector can inspire innovations in system calibration to optimize performance. Furthermore, advancements in technology integration have led to smarter, more efficient systems that can adapt to different surfaces and conditions. Stationary systems deliver higher performance for large-scale jobs with superior spray accuracy and uniform paint flow.

Cost Considerations and Investment

Cost considerations play a crucial role in choosing between mobile and stationary airless systems, as initial investments and ongoing expenses vary markedly. Price differences can be significant, with stationary systems often requiring a higher initial investment due to their larger size and complexity. Mobile systems typically cost less upfront, making them more accessible for smaller projects or businesses with limited budgets. However, you should also consider long-term costs, such as transportation, setup, and potential downtime. Stationary systems, while more expensive initially, might offer better efficiency and lower operating costs over time. Additionally, processing methods like grinding and roasting cacao beans demonstrate the importance of efficient systems for quality output. Understanding the cost-benefit analysis of each system type can help you make a more informed decision. Moreover, evaluating the initial purchase price against potential maintenance expenses can prevent unexpected costs down the line. It is also important to assess the system durability and how often maintenance might be required, which can impact overall costs. Selecting a system with modular components can facilitate easier repairs and upgrades, ultimately saving money. Ultimately, your choice depends on your project scope, frequency of use, and available capital. Balancing upfront costs with long-term value is key to making a sound investment decision.

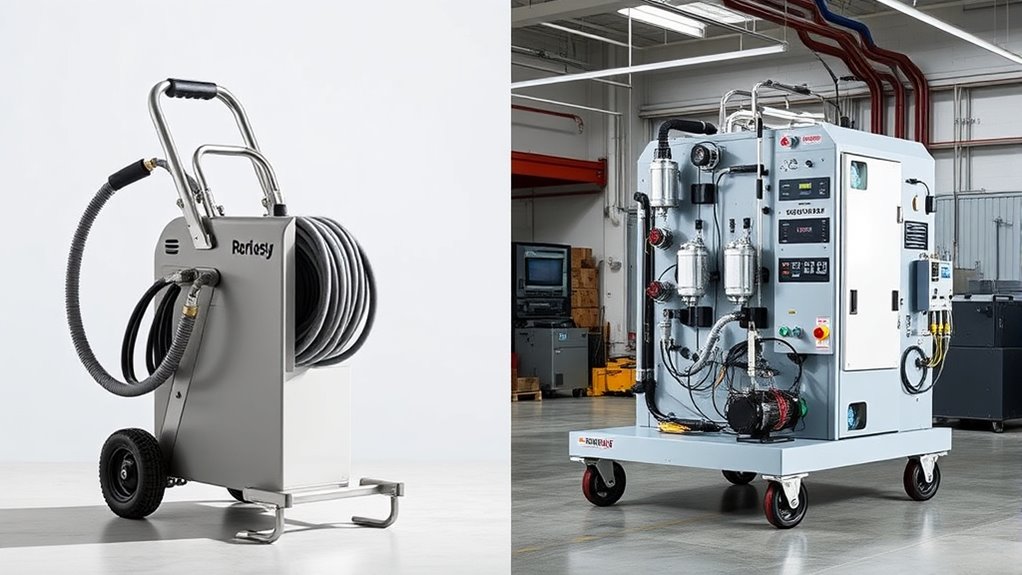

Maintenance and Operating Ease

While initial investment differences influence your choice, understanding how easy systems are to maintain and operate can substantially affect your long-term success. Mobile airless systems often rely on portable power sources like batteries, making setup quick and flexible, but they may require more frequent maintenance of batteries or chargers. Battery life is a critical factor to consider for mobile units, as it directly impacts operational time. Additionally, affordable maintenance of stationary systems typically results from their simpler design and dedicated power supply, which can simplify operation and reduce downtime. Noise levels also vary; stationary systems tend to operate more quietly, making them easier to use in noise-sensitive environments. Mobile units might generate higher noise, requiring extra precautions. Overall, stationary systems usually offer easier maintenance and smoother operation, while mobile systems prioritize flexibility but may demand more ongoing attention to keep them running efficiently. Furthermore, advances in automation technology can enhance the efficiency and ease of use of stationary systems, leading to reduced labor and operational costs. Modern innovations in system controls further contribute to streamlined operation and less user intervention.

Ideal Use Cases and User Preferences

Choosing between mobile and stationary airless systems depends heavily on your specific project needs and user preferences. If you prioritize versatility and easy color adjustments, mobile systems offer quick setup and variety in color options. Conversely, stationary systems excel for large-scale jobs, providing consistent performance and quieter operation in fixed locations. Your preference for noise levels can also influence your choice—stationary units tend to be quieter, ideal for noise-sensitive environments. Additionally, the sound vibrations produced by stationary systems can contribute to a more stable and controlled working environment. When considering the performance consistency of these systems, it’s essential to evaluate their impact on overall job quality and efficiency. For tasks requiring extensive coverage, stationary systems often deliver a more reliable output, which can reduce the need for rework. The maintenance requirements and oil quality monitoring are also crucial factors to consider for long-term operation. Consider the following:

| Use Case | User Preference |

|---|---|

| Small, on-the-go jobs | Desire for mobility and quick setup |

| Large, continuous projects | Need for stability and minimal noise |

| Color flexibility | Preference for diverse color options |

| Ease of operation | User-friendly controls for efficient workflow |

Frequently Asked Questions

How Do Airless Systems Impact Environmental Sustainability?

You can improve environmental sustainability by choosing airless systems, which promote eco-friendly coatings with minimal waste. These systems are highly energy-efficient, reducing power consumption during application. By using airless technology, you lower VOC emissions and decrease the need for excess material, helping protect the environment. Your choice of airless systems supports sustainable practices and contributes to a healthier planet through efficient, eco-conscious coating processes.

What Safety Precautions Are Necessary for Mobile Versus Stationary Systems?

Imagine you’re steering through a storm—safety is your lighthouse. For mobile systems, you’ll need personal protective equipment like gloves and masks, plus vigilant equipment maintenance to prevent mishaps on the go. Stationary systems demand similar precautions but focus more on securing equipment and ensuring proper setup. In both cases, staying alert and following safety protocols helps you avoid hazards, keeping your work environment safe and sound.

Are There Specific Regulations Affecting Mobile Airless System Usage?

You need to guarantee regulatory compliance when using mobile airless systems, as specific regulations often govern their operation. Licensing requirements vary by location, so check local laws to stay compliant. These regulations aim to promote safety and proper usage, so always verify if your system needs special permits or certifications. Staying informed helps you avoid penalties and ensures safe, legal operation of your mobile airless system.

Can These Systems Be Integrated With Existing Painting Equipment?

You can usually integrate mobile airless systems with your existing painting equipment, but it’s essential to verify equipment compatibility beforehand. Consider maintenance requirements, as combining systems might increase upkeep. Confirming compatibility helps prevent operational issues and prolongs equipment lifespan. Always review manufacturer guidelines and consult with suppliers to confirm integration options. Proper planning ensures smooth operation and maximizes your investment’s effectiveness without unnecessary downtime.

How Do System Sizes Influence Storage and Transportation Requirements?

You should consider how system sizes impact your storage efficiency and transportation challenges. Larger systems require more space, making storage less efficient and complicating transportation. Smaller, compact units are easier to store and move, reducing logistical issues. Opting for appropriately sized equipment helps streamline your operations, minimizes space requirements, and eases transportation, ensuring you can efficiently manage your painting projects without unnecessary hassle or costs.

Conclusion

Whether you choose the mobile or stationary airless system, think of it as finding the perfect dance partner—each has its own rhythm and grace. Mobile units offer freedom and flexibility, dancing easily across job sites, while stationary systems stand tall, providing steady, reliable performance. Your choice depends on your needs and style, but remember, whichever you pick, it’s about moving smoothly towards your goals. With the right system, your work will sing in perfect harmony.