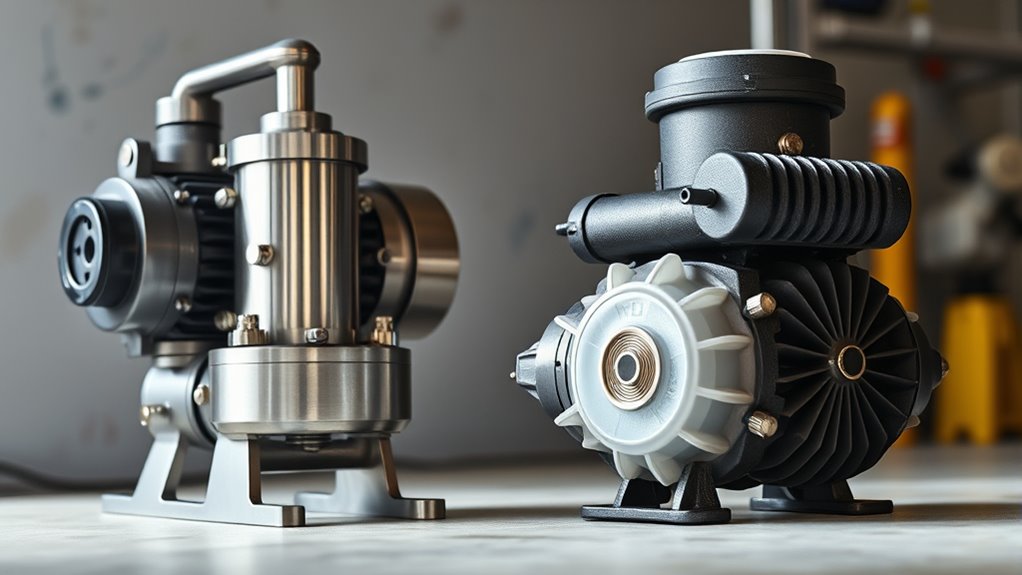

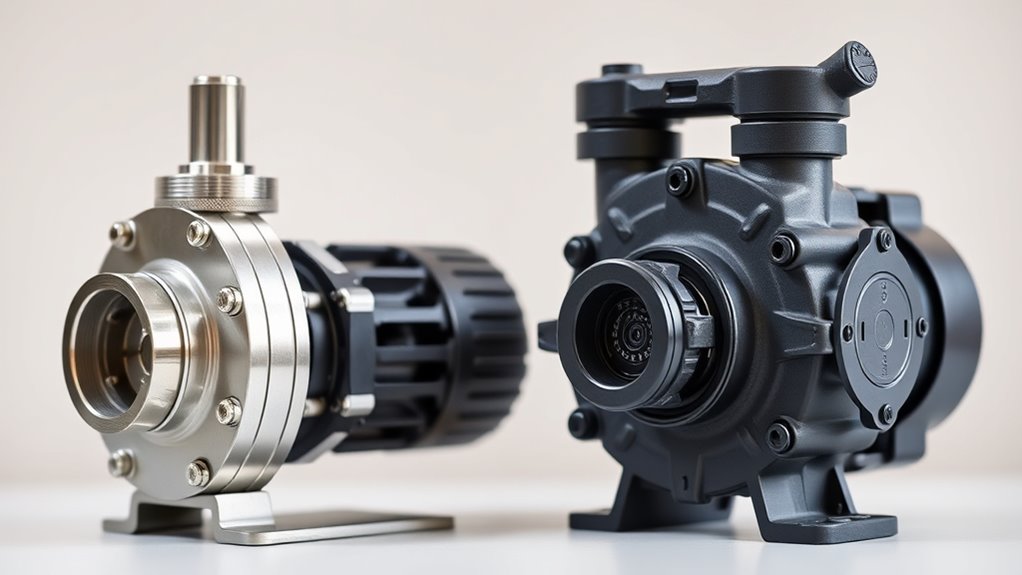

Piston pumps in airless sprayers use reciprocating motion to quickly generate high pressure, making them ideal for demanding, high-volume tasks, while diaphragm pumps rely on a flexible membrane to transfer fluids gently and handle corrosive or viscous materials. Piston types offer more power but need more maintenance, whereas diaphragm models excel in cleanliness and versatility. To understand which pump best fits your needs, especially for specific applications, keep exploring the key differences and advantages.

Key Takeaways

- Piston pumps in airless sprayers use reciprocating motion for high-pressure, rapid flow, ideal for demanding coating applications.

- Diaphragm pumps utilize a flexible membrane to transfer fluids smoothly, suitable for sensitive or corrosive materials.

- Piston pumps offer higher pressure and efficiency but require more maintenance and tend to be noisier.

- Diaphragm pumps provide quieter operation, simpler maintenance, and handle viscous or abrasive fluids effectively.

- Selecting between them depends on application needs, material compatibility, pressure requirements, and maintenance considerations.

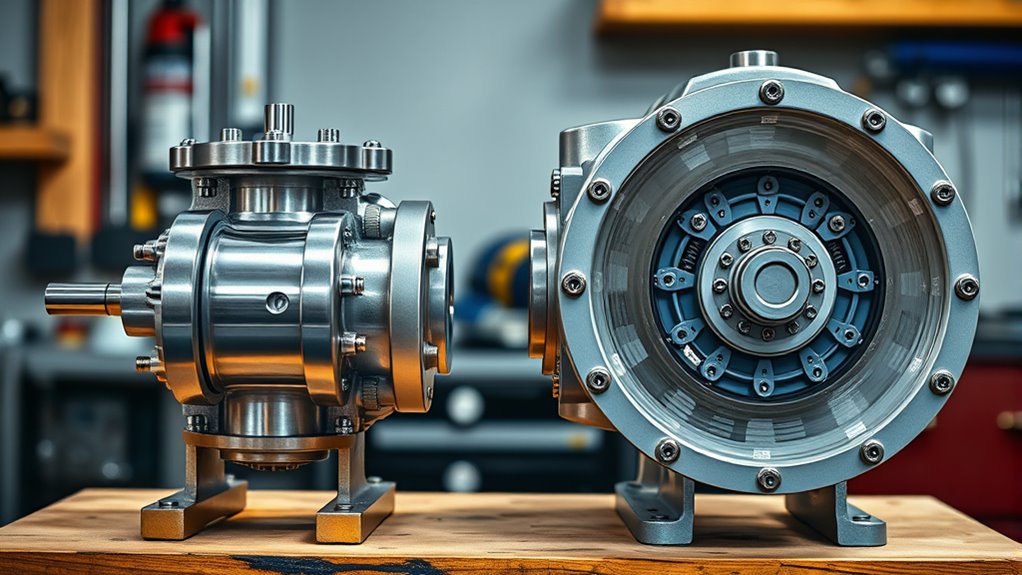

How Piston Pumps Operate in Airless Sprayers

Piston pumps operate by using a reciprocating motion to move paint or coating material through an airless sprayer. This movement relies on a piston that moves back and forth inside a cylinder, drawing in material on the intake stroke and pushing it out during the compression stroke. Proper pump maintenance is essential to keep the piston and seals in good condition, preventing leaks and ensuring consistent spray quality. Noise levels can be relatively high with piston pumps due to their mechanical action, so wearing hearing protection is advisable during extended use. Regularly inspecting and servicing the pump helps reduce noise and keeps the system running smoothly. By maintaining your piston pump, you’ll enjoy efficient performance and longer equipment lifespan. Additionally, choosing a vetted airless pump ensures reliable operation and optimal performance over time.

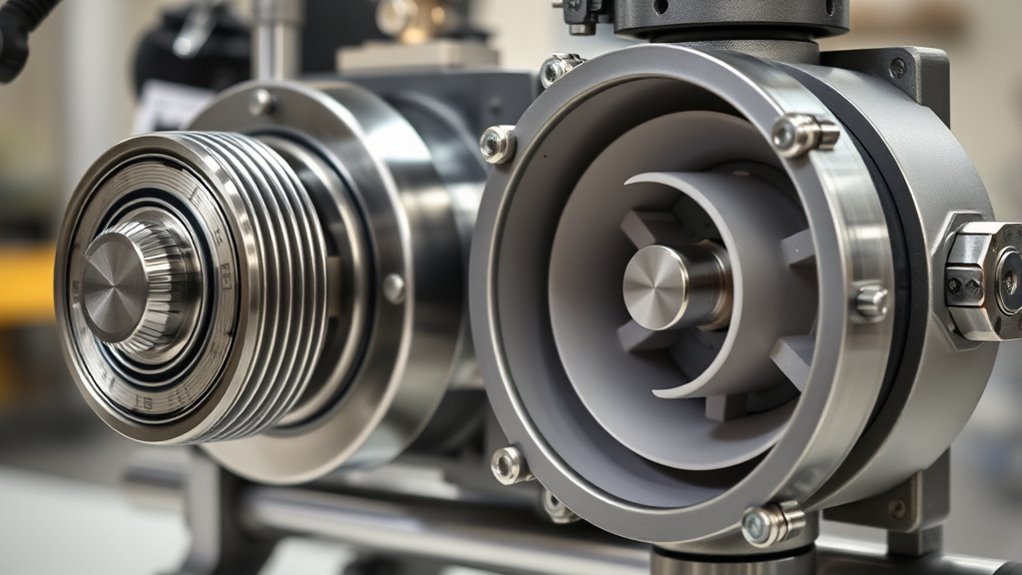

The Working Mechanism of Diaphragm Pumps

You’ll find that the diaphragm in these pumps moves back and forth in a precise rhythm. This movement creates a pump cycle that draws in and pushes out fluid efficiently. Understanding this cycle is key to grasping how diaphragm pumps operate. Additionally, the consistent operation ensures reliable performance across various applications.

Diaphragm Movement Dynamics

Diaphragm pumps operate through a flexible diaphragm that moves back and forth to create the necessary pressure differences for fluid transfer. This movement relies on mechanical oscillation, which drives the diaphragm’s motion in a precise, controlled manner. As the diaphragm flexes outward, it increases the volume of the pump chamber, causing fluid to enter through an inlet valve. When it moves back inward, it reduces the chamber’s volume, pushing the fluid out through the outlet valve. This continuous oscillation maintains fluid flow, with fluid dynamics playing a critical role in how efficiently the liquid moves through the system. Your understanding of these movement dynamics helps you appreciate how diaphragm pumps deliver consistent, reliable performance with minimal pulsation, ideal for airless spraying applications. Additionally, the filtration process within some pumps can help prevent contaminants from entering the system, ensuring smoother operation.

Pump Cycle Process

The pump cycle process in a diaphragm pump involves a continuous, coordinated sequence of movements that transfer fluid efficiently. When the diaphragm moves back during the intake stroke, it creates a vacuum that draws fluid into the chamber. As the diaphragm pushes forward in the compression stroke, the fluid is expelled through the outlet valve. This cyclical action ensures consistent fluid flow, directly impacting your pump’s efficiency. Because of its design, the diaphragm pump often requires minimal maintenance, but regular checks of seals and valves are essential to prevent leaks and maintain peak performance. Understanding this cycle helps you optimize your pump’s operation, ensuring reliable performance and reducing downtime. Properly managing the cycle process contributes to better pump efficiency and longevity.

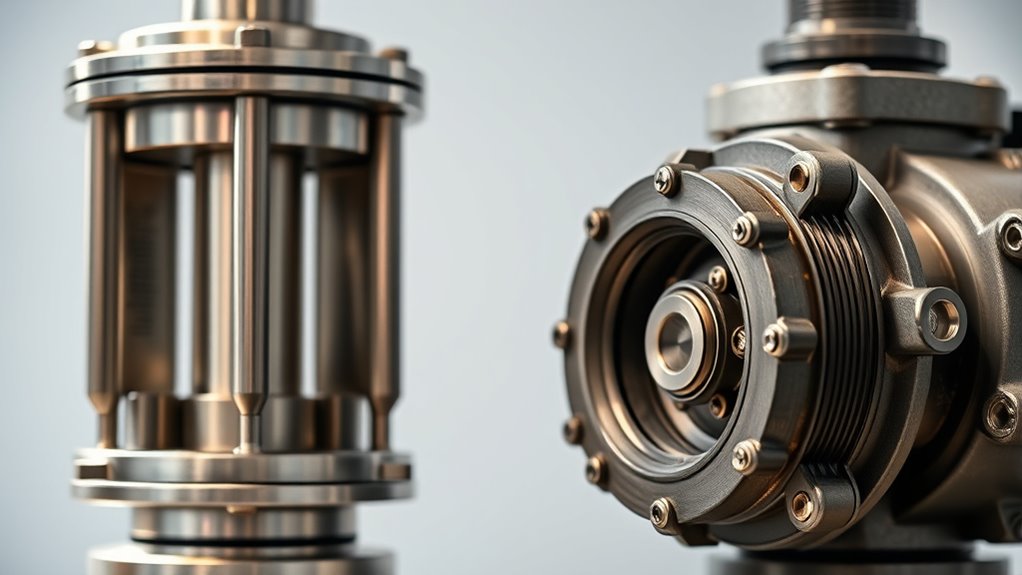

Key Performance Differences Between Piston and Diaphragm Pumps

When comparing piston and diaphragm pumps, understanding their key performance differences is essential for selecting the right one for your application. Piston pumps typically offer higher pressure capabilities and faster flow rates, making them suitable for demanding tasks. Diaphragm pumps excel in handling corrosive or abrasive materials, providing better durability in tough environments. In terms of cost efficiency, diaphragm pumps usually have lower initial investments and tend to require less maintenance, especially since they have fewer moving parts that wear out. Piston pumps, on the other hand, can incur higher maintenance requirements due to increased wear and tear on their components. Additionally, understanding the father-daughter bond can help appreciate the importance of choosing a pump that supports long-term reliability and performance. Your choice depends on balancing performance needs with long-term operational costs, ensuring you’re investing in a pump that aligns with your specific spraying needs.

Advantages and Disadvantages of Piston Pumps

Piston pumps are known for their ability to generate high pressure and deliver rapid flow rates, making them a popular choice for demanding applications. Their main advantages include powerful performance and precise control. However, they come with some drawbacks. Maintenance costs tend to be higher due to complex parts that require regular servicing. Noise levels can also be significant, which might be disruptive in certain environments. Here’s a quick comparison:

| Advantage | Disadvantage | Impact |

|---|---|---|

| High pressure output | High maintenance costs | Increased operational costs |

| Fast flow rates | Noise levels are loud | Noise disturbance |

| Precise control | Complex design | Skilled maintenance needed |

| Durable for heavy use | Larger size, less portable | Less flexibility in mobility |

| Long lifespan | Higher initial investment | Upfront costs are higher |

Additionally, piston pumps are often favored for their reliability in challenging conditions, ensuring consistent performance over time.

Advantages and Disadvantages of Diaphragm Pumps

Diaphragm pumps are widely appreciated for their ability to handle sensitive or viscous fluids without causing damage, making them ideal for applications requiring gentle, contamination-free transfer. They excel in providing reliable, leak-free operation and can handle corrosive or abrasive materials efficiently. However, they do have some downsides. For instance, pump maintenance can be more involved due to their complex diaphragm system, requiring regular checks to prevent failure. Additionally, they tend to be less cost-efficient upfront compared to simpler pump types, especially for small-scale use. On the upside, their durability and ability to operate with high-viscosity fluids can save you money over time. Proper maintenance practices are essential to ensure longevity and optimal performance of diaphragm pumps. Consider these factors when evaluating if a diaphragm pump suits your needs, balancing maintenance demands and cost efficiency.

Typical Applications for Each Pump Type

Both piston and diaphragm pumps find their niche in various industrial and commercial applications, each serving specific needs based on their design strengths. Piston pumps excel in high-pressure tasks like applying industrial coatings where precise, consistent flow matters. Diaphragm pumps shine in agricultural spraying, handling abrasive or corrosive materials with durability. Use piston pumps when you need powerful, steady output, especially in demanding environments. Diaphragm pumps are your go-to for versatile, chemical-resistant performance. Here’s a quick look at their typical uses:

| Application Type | Pump Type | Key Benefit |

|---|---|---|

| Industrial coatings | Piston pump | High pressure, precision |

| Agricultural spraying | Diaphragm pump | Durability, chemical resistance |

| Chemical transfer | Diaphragm pump | Versatility, corrosion resistance |

| Heavy-duty cleaning | Piston pump | Power, reliability |

| Food & beverage industry | Diaphragm pump | Clean, sanitary operation |

Factors to Consider When Choosing the Right Pump

When selecting the right pump for your needs, understanding the key factors involved can make all the difference. Consider your budget, as cost considerations influence your choice between piston and diaphragm pumps. Also, evaluate maintenance requirements—diaphragm pumps often need less frequent upkeep, making them more suitable for long-term use. Additionally, think about your application’s demands, such as pressure and flow rate, which impact pump performance. To help decide, keep these points in mind:

- Cost considerations: initial investment and ongoing expenses

- Maintenance requirements: frequency and complexity of upkeep

- Application needs: pressure, flow rate, and material compatibility

- Recognizing best-selling pumps can guide you toward options that balance performance and affordability.

Frequently Asked Questions

How Do Maintenance Requirements Differ Between Piston and Diaphragm Pumps?

You’ll find maintenance for piston and diaphragm pumps differ mainly in seal wear and lubrication needs. Piston pumps require regular seal inspections and lubrication to prevent wear and ensure smooth operation, which can be more intensive. Diaphragm pumps generally need less lubrication and are less prone to seal wear, making maintenance simpler. However, both need routine checks to keep them functioning efficiently and to avoid costly repairs.

Which Pump Type Offers Better Chemical Compatibility?

Did you know that diaphragm pumps typically handle a wider range of chemicals? You’ll find that their superior chemical resistance makes them more compatible with diverse materials, especially aggressive or corrosive substances. Their design guarantees better material compatibility, reducing risk of damage. If chemical compatibility is your priority, a diaphragm pump generally offers better performance, protecting your equipment and ensuring consistent results with various chemicals.

Are Piston or Diaphragm Pumps More Energy-Efficient?

When choosing a pump, you wonder which is more energy-efficient. Piston pumps typically consume more energy due to their higher power needs, but they offer greater durability and handle demanding tasks well. Diaphragm pumps are often quieter, reducing noise levels, and tend to be more energy-efficient for lighter applications. Your choice depends on balancing energy use, durability, and noise levels to match your specific spraying needs.

How Does Pump Size Impact Overall Sprayer Performance?

You’ll notice that pump size directly impacts your sprayer’s performance. A larger pump capacity delivers higher flow rates, making it easier to cover big areas quickly, especially with larger nozzle sizes. Conversely, a smaller pump might be more precise for detailed work. The right pump size balances capacity and nozzle size, ensuring efficient spraying without overworking the system. Adjusting these factors helps optimize your sprayer’s effectiveness.

What Are Common Troubleshooting Issues for Each Pump Type?

Ever wondered what could go wrong with your sprayer? You might face issues like seal wear or valve clogging that can disrupt your workflow. For piston pumps, seal wear often leads to leaks, while diaphragm pumps are prone to valve clogging, causing inconsistent spray patterns. Regular inspection and maintenance are key. Stay alert—addressing these problems early keeps your sprayer running smoothly and avoids costly repairs.

Conclusion

Choosing between piston and diaphragm pumps depends on your specific spraying needs. While piston pumps offer durability and high pressure, diaphragm pumps excel in handling abrasive or corrosive materials. Both have their strengths and weaknesses, so consider your application scope, material compatibility, and maintenance preferences. Ultimately, understanding their differences helps you make an informed choice—because in airless spraying, the right pump makes all the difference for a smooth, efficient job.