If you notice uneven spray patterns, drips, or inconsistent coverage, it’s time to check your spray tips. Visual signs like cracks, chips, or erosion indicate wear that can affect application quality. Changes in spray pattern or coverage mean your tips are deteriorating and need replacement. Regular inspections and monitoring help catch issues early, saving you time and waste. Keep an eye on these signs to guarantee peak performance—you’ll find more details ahead.

Key Takeaways

- Regular visual inspections help detect cracks, chips, erosion, or discoloration indicating wear.

- Changes in spray pattern, uneven coverage, or droplet size signal worn or damaged tips.

- Signs like reduced flow, overspray, or distorted spray shape suggest it’s time for replacement.

- Chemical corrosion and abrasive erosion accelerate tip deterioration, requiring timely replacement.

- Following maintenance schedules and monitoring wear patterns prevent inefficient application and equipment failure.

Common Signs of Spray Tip Wear

When spray tips begin to wear, you’ll notice several clear signs that indicate it’s time for a replacement. One of the most noticeable signs is a decrease in spray tip efficiency, which results in uneven or inconsistent spray patterns. You might see drips, runs, or areas with inadequate coverage, meaning the spray isn’t dispersing properly. Additionally, as the spray tip wears, you may find yourself performing maintenance more frequently. This increased maintenance frequency suggests the tip isn’t functioning at its best and could be clogging or developing damage. Paying attention to these signs helps you maintain peak spraying performance, reduces waste, and ensures consistent results. Recognizing early wear signs allows you to replace spray tips before spray quality declines markedly. Regular inspections and understanding wear patterns can help prolong the lifespan of your spray equipment and improve overall efficiency. Properly monitoring wear progression ensures timely replacements, preventing costly downtime.

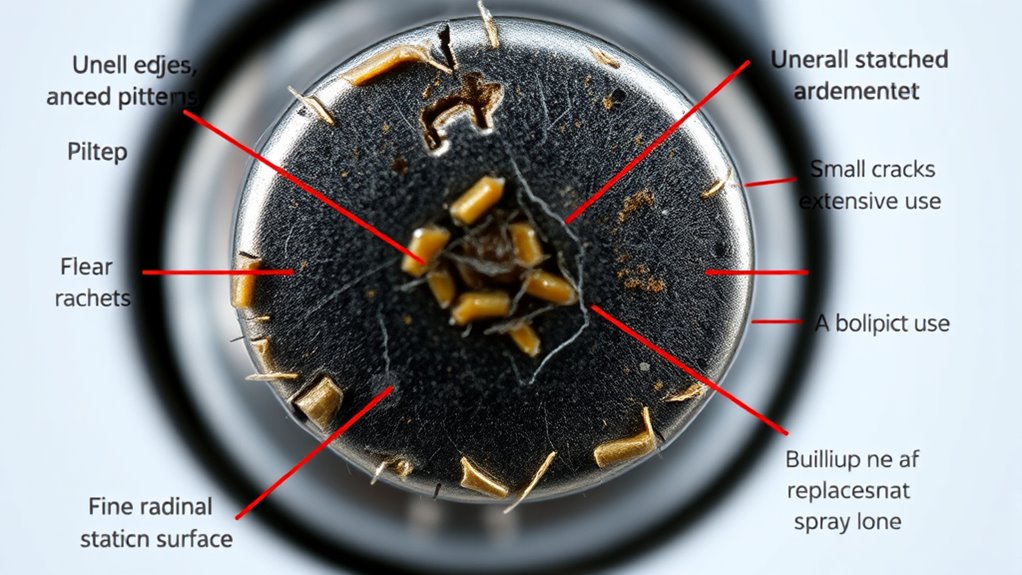

Visual Indicators of Wear and Damage

Visual indicators of wear and damage are among the most straightforward signs that your spray tip needs attention. You can often spot these through visual cues like chipping, cracks, or erosion on the tip’s surface. Wear detection becomes easier when you regularly inspect for uneven or rough edges, which can affect spray quality. Discoloration or buildup of debris can also signal damage or excessive wear. If the spray pattern looks inconsistent or the tip appears worn down, it’s time to consider replacement. These visual cues help you catch issues early, preventing poor spray performance and potential equipment failure. Regularly examining your spray tips for these indicators ensures proper operation and reduces the risk of costly downtime. Understanding the comparative advantage of timely maintenance can lead to more efficient operations and better resource utilization. Additionally, monitoring wear patterns can help extend the lifespan of your spray tips and maintain optimal spray quality. Incorporating preventive maintenance practices can further enhance the durability and performance of your spray equipment, especially by paying attention to technology advancements that improve wear detection and maintenance practices. Recognizing early signs of wear through detailed inspection is crucial for maintaining the performance and longevity of your spray tips.

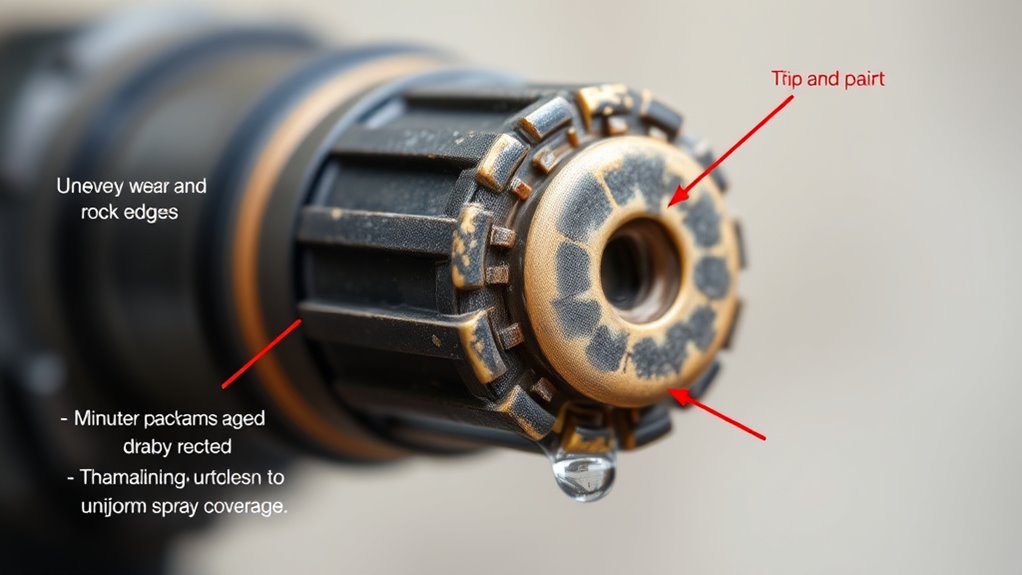

Changes in Spray Pattern and Coverage

Even if your spray tip looks fine upon inspection, changes in spray pattern and coverage can reveal underlying issues. You might notice uneven coverage or inconsistent spray pattern, which can signal wear or damage. Over time, a worn tip may produce irregular spray patterns, leading to poor coverage uniformity. This inconsistency can cause application problems, such as missed spots or overspray. Monitoring your spray pattern consistency regularly helps catch these issues early. When coverage becomes uneven or the pattern looks distorted, it’s a clear sign you should consider replacing the tip. Maintaining proper spray pattern and coverage uniformity ensures your application remains efficient and effective, preventing rework and saving you time and resources. Recognizing early signs of wear and tear in spray tips can help extend their lifespan and improve overall application quality. Additionally, paying attention to the type of paint and its viscosity can help you choose the right tip and avoid premature tip wear. Proper cleaning techniques can also prevent buildup that accelerates tip deterioration, contributing to longer-lasting, better-performing spray tips. Regular inspections and using the correct air pressure settings can further reduce unnecessary tip wear and ensure consistent spray coverage.

Impact of Wear on Application Quality

Worn spray tips directly compromise the quality of your application by causing uneven coating and inconsistent coverage. As the tip wears, the spray pattern becomes irregular, making it difficult to maintain application consistency. This leads to areas that are under-coated or over-coated, affecting the overall finish. Additionally, wear can weaken coating adhesion, resulting in poor bonding between the coating and the surface. Over time, this reduces durability and increases the likelihood of peeling or chipping. When your spray tips are worn, you may also notice more overspray and waste, further impacting efficiency. Using a proper connector can help ensure reliable operation of spray equipment and prevent unnecessary wear. Regular maintenance and inspection can also extend equipment lifespan and ensure optimal performance. Incorporating wear management practices and monitoring spray pattern consistency can further prevent costly repairs and minimize downtime. Proper equipment tuning practices can further optimize spray performance and reduce unnecessary wear.

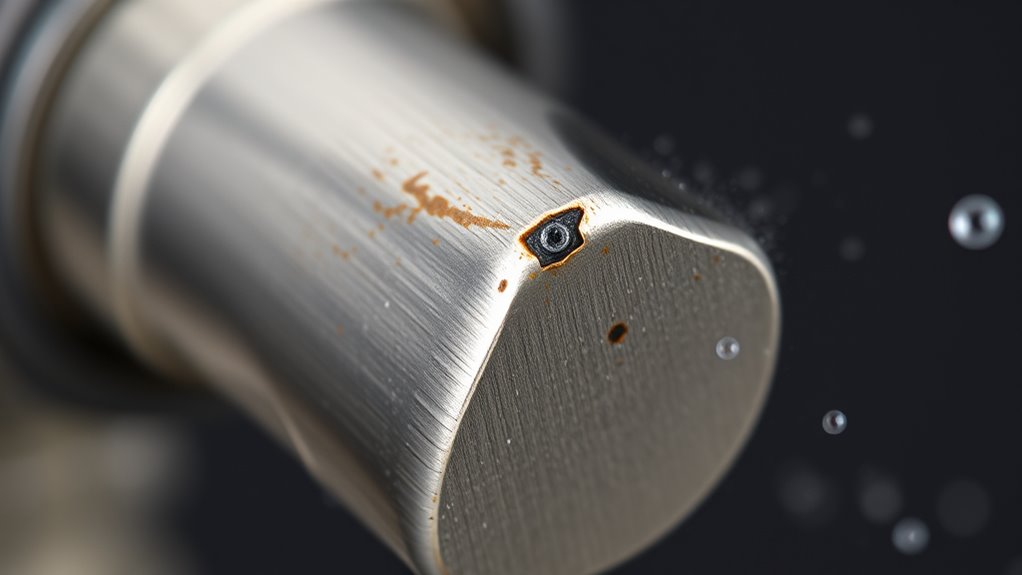

Causes of Spray Tip Deterioration

Spray tip deterioration results from several factors that accelerate wear and reduce performance. Chemical corrosion from aggressive chemicals can weaken the material, leading to cracks or pitting. Abrasive erosion occurs when particles in the fluid strike the tip at high velocity, gradually wearing down the surface. Both processes markedly shorten the tip’s lifespan.

| Cause | Effect | Prevention Tips |

|---|---|---|

| Chemical corrosion | Material degradation, cracks | Use chemical-resistant tips |

| Abrasive erosion | Surface thinning, roughening | Filter fluids, reduce particle load |

| High pressure | Increased wear and tear | Adjust operating pressure |

| Improper cleaning | Surface damage, corrosion | Use proper cleaning methods |

| Material fatigue | Cracks, failure over time | Regular inspection and replacement |

The Role of Material and Operating Conditions

The choice of materials and operating conditions directly influence spray tip wear and lifespan. Selecting the right material compatibility ensures your spray tips withstand the chemicals, abrasives, or corrosive agents they encounter daily. For example, hardened steel may resist wear better in abrasive environments, while ceramic tips excel with corrosive substances. Your operating environment also plays a pivotal role; high temperatures, humidity, or frequent pressure fluctuations accelerate wear. Operating under ideal conditions—maintaining consistent pressure, temperature, and chemical exposure—can extend your spray tip’s service life. Conversely, harsh environments increase the rate of deterioration, prompting earlier replacements. Understanding how environmental factors interact with material choices can help you optimize your spray tip’s durability and performance, reducing downtime and maintenance costs over time. Proper maintenance practices and monitoring wear patterns can further enhance the longevity of your spray tips, ensuring consistent application quality. Additionally, implementing preventive maintenance strategies can help identify early signs of wear before failure occurs, safeguarding your investment.

How to Inspect and Test Your Spray Tips

Regularly inspecting and testing your spray tips is essential to maintaining ideal performance and preventing costly downtime. Start with simple inspection techniques like visual checks for signs of wear, cracks, or uneven spray patterns. Use a magnifying glass or a flashlight to get a clearer view of any damage. Testing methods include measuring spray pattern consistency and flow rate to ensure proper atomization and coverage. You can also perform a flow test by capturing spray in a container to compare volume against specifications. Keep an eye out for changes in spray direction or droplet size, which indicate tip wear. By regularly combining visual inspections with functional testing, you catch issues early and maintain excellent spray efficiency.

Best Practices for Timely Replacement

To guarantee your spray tips operate at peak efficiency, it’s essential to replace them promptly when signs of wear appear. Establishing a maintenance schedule helps you stay ahead of issues, ensuring consistent spray quality. Regularly check for uneven spray patterns or reduced flow, indicating the need for replacement. Follow recommended replacement intervals based on usage and wear patterns to prevent performance decline. Keep detailed records to adjust your schedule as needed. Being aware of proper maintenance practices can also help ensure your investments remain compliant and secure.

Frequently Asked Questions

How Often Should Spray Tips Be Replaced for Optimal Performance?

You should follow maintenance schedules and regularly check wear indicators to determine when to replace spray tips. Typically, replace them every 200 to 300 hours of use or if you notice spray pattern inconsistencies, clogs, or uneven distribution. Monitoring wear patterns helps you catch issues early, ensuring peak performance. Always inspect tips before each use and adhere to manufacturer guidelines to maintain efficiency and prevent costly damage.

Can Improper Maintenance Accelerate Spray Tip Wear?

Improper maintenance can definitely speed up spray tip wear. If you don’t follow maintenance best practices, like cleaning tips regularly and checking for clogs, you risk uneven wear patterns. This can cause early deterioration and reduce spray quality. By routinely inspecting wear patterns and maintaining your equipment properly, you extend spray tip life and ensure consistent performance. Neglecting these steps accelerates wear and leads to more frequent replacements.

Are There Specific Spray Tip Materials That Last Longer?

Think of tip material as the armor protecting your spray tips. Tungsten or ceramic tips often act like the marathon runners of wear longevity, lasting longer under tough conditions. These durable materials resist wear and tear better than standard brass. By choosing the right tip material, you extend your spray tip’s lifespan, ensuring consistent performance and saving you time and money. Always consider your project needs when selecting tip material for peak wear resistance.

What Are the Environmental Factors Affecting Spray Tip Durability?

Environmental factors like moisture, humidity, and exposure to UV rays directly impact spray tip durability. You’ll notice corrosion resistance decreases when tips face moisture, leading to faster wear. UV stability also plays a role; prolonged sun exposure can degrade materials, causing cracks or deterioration. To maximize lifespan, choose tips with strong corrosion resistance and UV stability, and regularly inspect your equipment to catch early signs of environmental damage.

How Does Spray Tip Wear Influence Environmental Safety Compliance?

Your spray tip wear can dramatically impact environmental safety compliance, potentially causing a cascade of issues. Worn tips may lead to uneven application, increasing environmental impact and risking regulatory standards violations. By regularly inspecting and replacing worn tips, you guarantee consistent spray quality, reduce waste, and stay aligned with environmental and regulatory standards. Think of it as safeguarding the environment with every spray, preventing costly penalties and ecological damage.

Conclusion

By keeping a close eye on wear signs, you can catch issues before they spiral out of control. Regular inspections are your best defense, ensuring your spray tips stay sharp and effective. Think of your spray tips as the heartbeat of your application process—when they falter, everything suffers. Stay proactive, replace them timely, and keep your results on point like a well-tuned instrument. After all, prevention is the best medicine for smooth, flawless coverage.