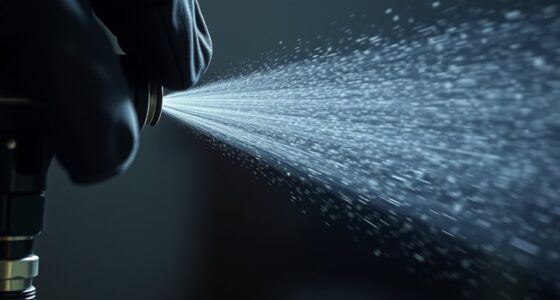

If you’re experiencing poor paint atomization, start by checking your nozzle for clogs or damage, ensuring it’s clean and properly assembled. Adjust your equipment’s pressure settings—too much or too little can affect spray quality. Verify your paint’s viscosity; if it’s too thick, thin it out with the right solvent, and stir thoroughly. Regular maintenance of filters and parts can prevent issues from worsening. Keep exploring for more detailed tips to achieve a smooth, even spray.

Key Takeaways

- Check and clean the spray nozzle for clogs or damage to ensure proper paint flow.

- Verify that paint viscosity falls within recommended ranges; adjust with suitable thinner if needed.

- Adjust pressure settings to optimize atomization without causing overspray or uneven spray patterns.

- Regularly inspect and maintain filters, seals, and other components to prevent blockages and leaks.

- Confirm proper paint mixing and avoid lumps to ensure consistent paint consistency for better atomization.

If you’re experiencing issues with paint atomization, troubleshooting can help you identify and resolve common problems quickly. One of the first areas to check is the spray nozzle, as spray nozzle issues are often the root cause of poor atomization. If the spray pattern is irregular, drips, or uneven, it’s likely that the nozzle is clogged, damaged, or improperly assembled. Clogs can occur from dried paint or debris, so inspect the nozzle carefully and clean it thoroughly with the appropriate solvent or brush. If the nozzle is damaged or worn out, replacing it can restore proper spray patterns and improve atomization. Also, ensure the nozzle is correctly tightened and aligned to prevent uneven spray or inconsistent paint flow.

Next, consider the paint viscosity, which plays a vital role in how well the paint atomizes. If the paint is too thick, it won’t break apart into fine droplets, leading to a rough or spattered finish. Conversely, if it’s too thin, it may spray too heavily or cause overspray, wasting material and creating an uneven coating. To troubleshoot this, measure the paint viscosity with a viscometer or follow manufacturer recommendations for thinning. Adjust the viscosity by adding the appropriate thinner or solvent gradually, then test spray to see if atomization improves. Remember, each sprayer and paint type has ideal viscosity ranges, so adhering to those guidelines is essential.

Check and adjust paint viscosity for optimal atomization and a smooth finish.

Also, check your equipment settings. Sometimes, improper pressure or flow rate can cause poor atomization. If your sprayer allows, increase the pressure slightly to see if the spray smooths out and becomes more consistent. Too high pressure can cause overspray and a rough finish, so make small adjustments and test after each change. Likewise, verify that your paint is properly mixed; uneven mixing or settling can affect viscosity and spray consistency. Stir or shake the paint thoroughly before spraying and ensure no lumps or separation are present.

Finally, inspect the entire spray system for blockages, leaks, or wear. Regular maintenance, such as cleaning filters and replacing worn parts, prevents issues from escalating. If you’ve addressed nozzle issues, confirmed proper paint viscosity, and adjusted equipment settings but still face poor atomization, it might be time to consult the manufacturer’s guidelines or seek professional assistance. Additionally, understanding the importance of oxidative stress and its effects on paint quality can help you maintain optimal spray conditions. Troubleshooting these common areas can greatly improve your spray quality, saving you time, material, and frustration.

Frequently Asked Questions

How Does Humidity Affect Paint Atomization?

Humidity effects can notably impact paint atomization by altering paint consistency. When humidity is high, it adds moisture to the air, causing your paint to thicken or become too watery, which hampers proper atomization. This results in uneven spray patterns and poor finish. To avoid this, work in a controlled environment with ideal humidity levels, and consider adjusting your paint mixture or using additives to maintain proper consistency.

Can Incorrect Nozzle Size Cause Poor Atomization?

Think of your spray gun like a vintage camera; using the wrong lens can distort the image. An incorrect nozzle size definitely causes poor atomization. It affects the spray pattern, making it uneven or too coarse. Proper nozzle selection guarantees a smooth, consistent spray. If the nozzle is too small or large for your paint and application, you’ll struggle with an even coat, wasting paint and time. Choose wisely to get that perfect finish.

What Role Does Paint Viscosity Play in Atomization?

Paint viscosity plays a vital role in atomization because it directly affects paint flow. If the viscosity is too high, the paint becomes thick, making it harder to atomize properly, resulting in uneven spray. You should focus on viscosity control to guarantee smooth paint flow, which helps create fine, consistent droplets. Adjust your thinning process or use additives to optimize viscosity, improving overall atomization and finish quality.

How Does Ambient Temperature Impact Spray Performance?

Imagine your spray pattern dancing gracefully, but when ambient temperature fluctuates, it’s like the weather nudging that dance. Warmer temps make paint flow more smoothly, enhancing atomization, while cooler temperatures can cause it to thicken, disrupting the spray pattern. Temperature fluctuations can lead to inconsistent paint delivery, so maintaining stable conditions helps make certain your spray pattern stays precise and even, giving you a flawless finish every time.

Are There Specific Equipment Brands Better for Fine Atomization?

You should consider equipment brands known for precision and consistency, like Graco, Wagner, or Devilbiss, as they often produce high-quality spray guns ideal for fine atomization. When selecting nozzles, opt for those designed for detailed work, such as smaller or specialized nozzles, which help attain smoother, finer spray patterns. Investing in reputable brands and the right nozzle selection guarantees better control and improved spray performance.

Conclusion

When paint refuses to dance smoothly from your spray gun, it’s like trying to tame a wild stallion—frustrating and unpredictable. But with patience and a keen eye, you can coax that paint into a fine, even mist. Think of troubleshooting as whispering sweetly to your equipment, guiding it back to harmony. With each adjustment, you’re painting a masterpiece, turning chaos into a symphony of perfect atomization. Keep refining, and your spray gun will sing beautifully again.