To winterize your airless sprayer for cold storage, you should drain and flush the system with solvent-based cleaner, then thoroughly clean and dry filters, hoses, and the spray gun. Make sure all paint, solvents, and water are removed to prevent freezing damage. Protect hoses, cables, and the pump, and store everything in a dry, temperature-controlled place. Proper maintenance now helps keep your sprayer in great shape for next season—more tips await if you keep going.

Key Takeaways

- Drain and flush the system with solvent-based cleaner to remove residual paint and prevent freezing damage.

- Properly drain hoses, filters, and nozzles; store them in a dry, frost-free environment.

- Protect hoses and cables by draining, insulating, and storing in controlled, moisture-free areas.

- Clean and dry the spray gun and other components thoroughly before storage to prevent rust and clogs.

- Store the pump and motor indoors or in insulated shelter, and cover to shield from moisture and temperature fluctuations.

Draining and Flushing the System

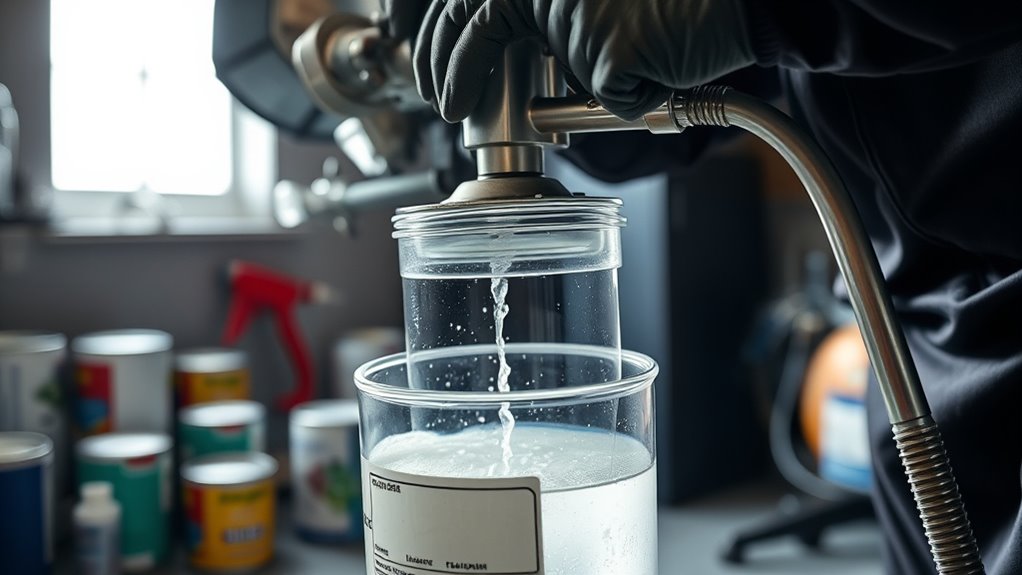

Before storing your airless sprayer for winter, it’s essential to drain and flush the system thoroughly. This prevents leftover paint or solvent from freezing and causing damage. Start by releasing all pressure and emptying the paint from the pump and hoses. Use clean, solvent-based cleaner to flush out residual paint, ensuring the internal components stay clear. Proper winter insulation around your equipment adds an extra layer of frost protection, especially in unheated spaces. Draining the system reduces the risk of ice forming inside, which can crack parts or block fittings. Additionally, consulting industry best practices can help ensure comprehensive winterization procedures. By taking these steps, you safeguard your sprayer against cold damage, ensuring it remains functional when you’re ready to use it again. Proper draining and flushing are critical for effective winter storage.

Removing and Cleaning the Filters

Removing and cleaning the filters is a crucial step to guarantee your sprayer stays in top condition during winter storage. Proper filter maintenance prevents clogs and ensures smooth operation when you resume use. Carefully detach the filter from your sprayer, following the manufacturer’s instructions. Rinse it thoroughly with solvent or water to remove paint residue and debris. If the filter shows signs of damage or excessive wear, consider filter replacement to maintain ideal performance. Regular cleaning extends the filter’s lifespan and keeps your sprayer functioning efficiently. Be sure to dry the filter completely before reinstalling or storing it. Skipping this step can lead to blockages and costly repairs later, so don’t overlook the importance of clean filters in your winterization process. Additionally, understanding the specific Hyundai Tuning options available can help you optimize your vehicle’s performance once the season changes.

Clearing Remaining Paint and Solvents

Start by properly draining any remaining paint from your sprayer to prevent clogs during storage. Use a solvent to clean out residual paint and guarantee all parts are thoroughly rinsed. Finally, make sure the equipment is completely dry before storing it for the winter. Ensuring all components are free of moisture helps prevent rust and damage during cold storage, especially for equipment like electric dirt bikes that may be stored outdoors or in unheated spaces.

Properly Drain Remaining Paint

To guarantee your airless sprayer stays in good condition during cold weather storage, you need to properly drain any remaining paint and solvents. First, ensure the paint consistency is thin enough to flow easily, making draining simpler. Remove the nozzle and clean it thoroughly to prevent clogs and ensure proper nozzle maintenance. Next, open the drain valve or relieve pressure to let the leftover paint flow out. Tilt the sprayer to reach all internal surfaces, ensuring no residual paint remains that could thicken or freeze. Wipe down any accessible parts and inspect the nozzle for clogs. Proper drainage prevents paint from hardening inside the system, which can cause damage and make future cleanups more difficult. This step is vital for preserving your sprayer’s performance during winter storage. Additionally, understanding the contrast ratio of your equipment can help you assess the clarity and depth of your stored paint’s color, ensuring optimal results when you resume use.

Use Solvent for Cleanup

After draining the remaining paint, using a solvent is the next step to thoroughly clean your airless sprayer. Choose an appropriate solvent based on the type of paint used, and follow the manufacturer’s instructions. Always prioritize solvent safety by working in a well-ventilated area and wearing protective gear like gloves and goggles. Proper disposal guidelines are essential; never pour solvents down drains or onto the ground. Instead, store leftover solvent in a sealed container or take it to a hazardous waste disposal facility. Cleaning with solvent ensures all residual paint and chemicals are removed, preventing clogs and damage during storage. Additionally, selecting the right cleaning method can improve your tuning process by maintaining optimal equipment performance. Remember, careful handling and proper disposal keep you safe and protect the environment.

Ensure Equipment Is Dry

Ensuring your equipment is completely dry is crucial to prevent rust, corrosion, and freezing damage during cold storage. Proper equipment maintenance involves thoroughly removing any remaining paint, solvents, or cleaning solutions. Use compressed air or a clean cloth to wipe down all parts, paying close attention to nozzles, hoses, and filters. Moisture left inside can freeze, causing cracks or other damage. Follow these winter storage tips to avoid costly repairs later. Make sure to disassemble removable parts and dry them separately. Once everything is dry, reassemble your sprayer, store it in a dry, protected area, and consider applying a light coat of lubricant to moving parts. Keeping your equipment dry ensures it remains in good condition and ready for use when the weather warms up. Additionally, understanding the importance of proper equipment care can extend the lifespan and performance of your sprayer.

Lubricating Moving Parts

Lubricating the moving parts of your airless sprayer is essential to keep it running smoothly during storage in cold weather. Proper sprayer lubrication prevents rust and corrosion, ensuring your equipment stays in good condition. Focus on applying lubricant to key moving parts like the trigger, pump, and pressure control mechanisms. Use a high-quality, weather-resistant lubricant designed for sprayers to avoid gumming or freezing. Before applying, clean off any dirt or old grease to ensure effective lubrication. Moving parts that aren’t properly lubricated can seize up or become difficult to operate over time. Regular lubrication during winter storage helps maintain the sprayer’s performance, so it’s ready to use when warm weather returns. Keep these components well-lubricated for optimal performance and ideal sprayer longevity.

Protecting Hoses and Cables

To protect your hoses and cables during winter, start by ensuring proper drainage to prevent water from freezing inside. Consider storing them in a controlled environment that minimizes exposure to moisture and extreme temperatures. Insulating your hoses and cables adds an extra layer of defense against cold damage, keeping them flexible and functional when you need them. Additionally, understanding data privacy challenges can help you be aware of the importance of safeguarding your equipment and information from potential cyber threats during storage.

Proper Hose Drainage Techniques

Proper hose drainage is essential to prevent freezing and damage during cold weather storage. To guarantee this, you should first perform hose maintenance by disconnecting hoses and cables from your sprayer. Next, always release the pressure before draining to avoid accidental spray or injury. Proper pressure release helps clear residual paint or fluid, reducing the risk of freezing inside the hose. To drain effectively:

- Hang hoses vertically to let remaining liquids flow out completely

- Use a clean cloth or compressed air to remove stubborn moisture

- Store hoses in a warm, dry area to prevent condensation buildup

- Incorporate effective drainage techniques to ensure thorough removal of liquids

Taking these steps minimizes the risk of hose cracking or bursting due to ice formation. Proper drainage preserves your hoses and extends their lifespan, ensuring they’re ready for use when warm weather returns.

Storage Environment Considerations

After draining hoses correctly, the next step is to contemplate how and where you store them. You should keep hoses and cables in a dry, indoor climate that prevents moisture buildup. A controlled environment reduces the risk of freezing and cracking, extending their lifespan. Confirm the storage space has good ventilation quality to prevent humidity from accumulating, which can lead to mold or corrosion. Avoid areas prone to temperature fluctuations or dampness, such as garages or sheds, unless they’re well-insulated. Store hoses and cables in a way that prevents kinks or crushing, keeping them off the floor to avoid damage. Proper storage environment considerations help maintain their flexibility and integrity, ready for use when you need them again. Additionally, considering the best anime movies can provide relaxing entertainment during storage or maintenance sessions.

Insulating Cables and Hoses

Since hoses and cables are vulnerable to freezing temperatures, insulating them is essential to prevent damage during cold weather storage. Properly insulating cables and hoses helps maintain their flexibility and prevents cracks caused by freezing. To protect your equipment, consider these tips:

- Wrap insulating cables with foam or rubber sleeves to keep out moisture and cold.

- Use specialized insulating hoses designed for cold weather to prevent cracking and splitting.

- Secure insulation with tape or clips, ensuring no gaps where cold can seep in.

- Additionally, using climate-controlled storage can further safeguard your equipment from extreme cold damage.

Storing the Spray Gun Properly

To guarantee your airless sprayer remains in top condition during colder months, it’s essential to store the spray gun properly. First, clean the spray gun thoroughly to remove any paint residue or debris, preventing clogs or corrosion. Once clean, dry it completely to avoid moisture buildup. Store the spray gun in a designated storage container that keeps it protected from dust, dirt, and accidental damage. Make sure the container is clean and dry, and consider using a cover or wrapping the gun in a cloth for added protection. Keep the spray gun in a dry, temperature-controlled area to prevent freezing or damage. Proper storage ensures your spray gun stays in good working condition, ready for use when warmer weather returns. Regular maintenance and proper storage also help extend the longevity of tools, ensuring reliable performance over time.

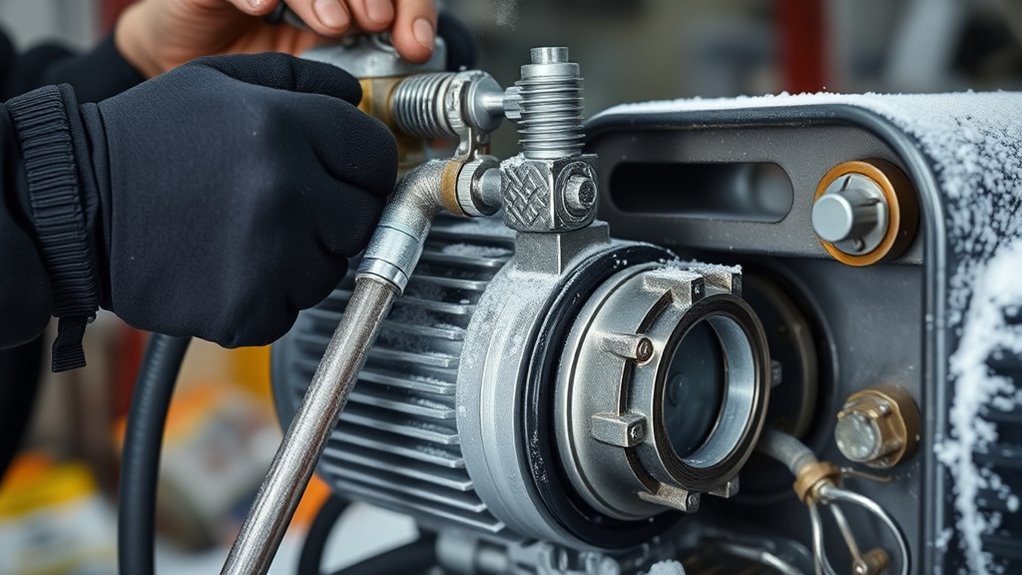

Protecting the Pump and Motor

Properly safeguarding the pump and motor during cold storage helps prevent freeze damage and corrosion. To guarantee pump protection and motor safeguarding, take these steps:

- Drain all residual paint and fluids to avoid freezing inside the pump and motor components.

- Use antifreeze designed for sprayers to fill the pump and lines, preventing ice formation.

- Cover the motor with a weatherproof cover or tarp to shield it from moisture and temperature fluctuations.

Choosing the Right Storage Location

Choosing the right storage location is essential to keep your airless sprayer in top condition during the off-season. You should prioritize an indoor climate that maintains a consistent temperature, ideally above freezing, to prevent any damage from cold snaps. If indoor storage isn’t an option, an outdoor shelter like a shed or garage can work, but ensure it offers insulation and protection from extreme weather. Avoid places exposed to rain, snow, or direct sunlight, as moisture and temperature fluctuations can harm your equipment. The goal is to keep your sprayer in a stable environment that minimizes exposure to harsh elements, preserving its functionality and extending its lifespan during winter months. Incorporating sound healing science principles, such environments can help maintain the equipment’s optimal performance by reducing vibrations and stress caused by temperature shifts.

Performing Routine Inspections Before Storage

Before storing your airless sprayer for winter, it’s important to perform a thorough inspection to catch any issues that could worsen over time. Check the equipment calibration to ensure accuracy and proper operation next season. Inspect the spray tip and nozzle for clogs or damage, replacing if necessary. Verify that safety equipment, like masks and gloves, are clean and in good condition. Also, examine hoses and seals for cracks or leaks to prevent future malfunctions. Consider cleaning all components to remove paint residue and debris, reducing corrosion risks. Additionally, inspecting the Honda Tuning components can help identify potential mechanical issues that may affect the sprayer’s performance. By doing this, you can identify potential problems early and ensure your sprayer is ready for storage. Regular inspections help maintain equipment longevity and safety, making spring startup smoother.

Frequently Asked Questions

How Often Should I Perform Winter Maintenance on My Airless Sprayer?

You should perform seasonal maintenance on your airless sprayer at least once a year, ideally before storing it for winter. Regularly check and clean your equipment, applying proper storage tips to prevent damage from cold weather. If you use your sprayer frequently or notice any issues, consider more frequent maintenance. Proper winterizing guarantees your sprayer stays in good condition, ready for use when the warmer season returns.

Can I Leave Leftover Paint in the System During Winter Storage?

Leaving leftover paint in your sprayer isn’t recommended, even during winter storage. Paint residue can harden and clog the system, making it difficult to use later. To prevent issues, always follow storage tips like cleaning the system thoroughly before storing it for the season. Proper maintenance guarantees your sprayer stays in good condition, ready for use when warmer weather returns. Always empty and clean your sprayer after each project.

What Safety Precautions Are Necessary When Winterizing the Sprayer?

When winterizing your sprayer, you need to prioritize safety. Always wear personal protective equipment like gloves, goggles, and a mask to prevent chemical exposure. Handle cleaning solutions and chemicals carefully, following manufacturer instructions. Make certain you’re in a well-ventilated area to avoid inhaling fumes. Proper chemical handling reduces risks, and wearing safety gear protects you from splashes or spills. Taking these precautions keeps you safe during the winterization process.

Is It Necessary to Disassemble Parts for Winter Storage?

Think of your sprayer as a delicate symphony that needs careful tuning before winter’s silence. Disassembly requirements become your sheet music, guiding you through winter storage procedures. You should disassemble parts like the nozzle and hoses to prevent freezing damage, ensuring the sprayer’s longevity. Following proper disassembly steps safeguards your equipment, making your spring startup smooth and hassle-free. Neglecting this step risks costly repairs, so don’t skip the critical notes in winterizing.

How Do I Prevent Freezing Damage to the Pump and Hoses?

To prevent freezing damage to your pump and hoses, you should apply antifreeze specifically designed for sprayers. Make sure to run the antifreeze through the system to protect internal components. Additionally, insulate your hoses with hose insulation to prevent cold air from causing damage. These steps help guarantee your equipment stays safe during winter, avoiding costly repairs and extending its lifespan.

Conclusion

By winterizing your airless sprayer, you’re basically transforming it into a winter-proof superhero, ready to conquer the coldest months without a hitch. If you skip these steps, your sprayer might as well be a frozen popsicle, useless and broken. So, follow these tips diligently—think of it as giving your equipment a cozy winter blanket. Trust me, your sprayer will thank you when spring rolls around, and you’ll save a fortune on repairs!