To reset electrical components in digital control units, start by ensuring the system is safely powered down and unplugged. Use approved tools to disconnect power sources carefully, then perform manual resets if needed, such as pressing reset buttons or following manufacturer instructions. Reconnect everything securely, power the system back on, and verify proper operation. Following these steps helps prevent future issues and extends component life—continue exploring to master each stage effectively.

Key Takeaways

- Power down the system completely, disconnect power sources, and wait for components to discharge before resetting.

- Use appropriate tools and safety gear, such as insulated tools and anti-static wrist straps, during the reset process.

- Follow manufacturer-specific procedures, including software resets or manual controls, to properly reset electrical components.

- Check for faults or damage after resetting, and reconfigure settings or update firmware as needed.

- Document the reset process and monitor system stability to prevent recurring issues and ensure safe operation.

Understanding the Purpose of Resetting Digital Control Units

Resetting digital control units is an essential process that helps maintain ideal performance and troubleshoot issues. When you experience a digital fault, such as a system glitch or error, resetting can clear the error and restore normal operation. Power fluctuation is a common cause of digital faults, disrupting the unit’s ability to function correctly. Resetting helps the control unit recalibrate itself, eliminating temporary glitches caused by inconsistent power supply or minor faults. This process ensures the system runs smoothly and prevents minor issues from escalating into more serious problems. Regular resets, especially after power fluctuations, keep your digital control units functioning efficiently. Additionally, understanding the importance of system calibration can help optimize device performance and longevity. Performing resets periodically can also prevent the accumulation of software bugs that may hinder system responsiveness. Proper resetting also aids in refrigeration cycle stability, ensuring the system maintains optimal heat transfer and efficiency. Incorporating AI-driven diagnostics can further assist in early detection of potential faults, reducing downtime and maintenance costs. Implementing electrical system checks can help identify underlying issues that might cause faults, especially in complex electronic systems. Ultimately, resetting is a proactive step to maintain system stability, extend equipment lifespan, and avoid costly repairs.

Identifying Common Electrical Issues Requiring a Reset

Electrical issues are often the root causes behind digital control unit malfunctions that require a reset. Recognizing these signs helps you act promptly. Common problems include sudden system crashes, unresponsive displays, and inconsistent performance. Electrical surges can overload circuits, leading to erratic behavior and damage. Component corrosion, caused by moisture or dirt, may cause poor connections or faulty signals. Other issues involve voltage fluctuations and wiring faults. Additionally, AI integration in modern devices can sometimes interfere with electrical systems, causing unpredictable behavior. By identifying these symptoms early, you can determine if a reset is needed before more serious damage occurs. Keep an eye out for:

- Unexpected system resets or shutdowns

- Flickering or blank screens

- Unusual error messages

- Loss of calibration or settings

- Physical signs of corrosion or burnt components

- Signs of spoilage such as discoloration or off-smell, can also indicate underlying electrical issues affecting control units. Additionally, understanding electrical surges and their impact can help prevent damage and ensure proper functioning.

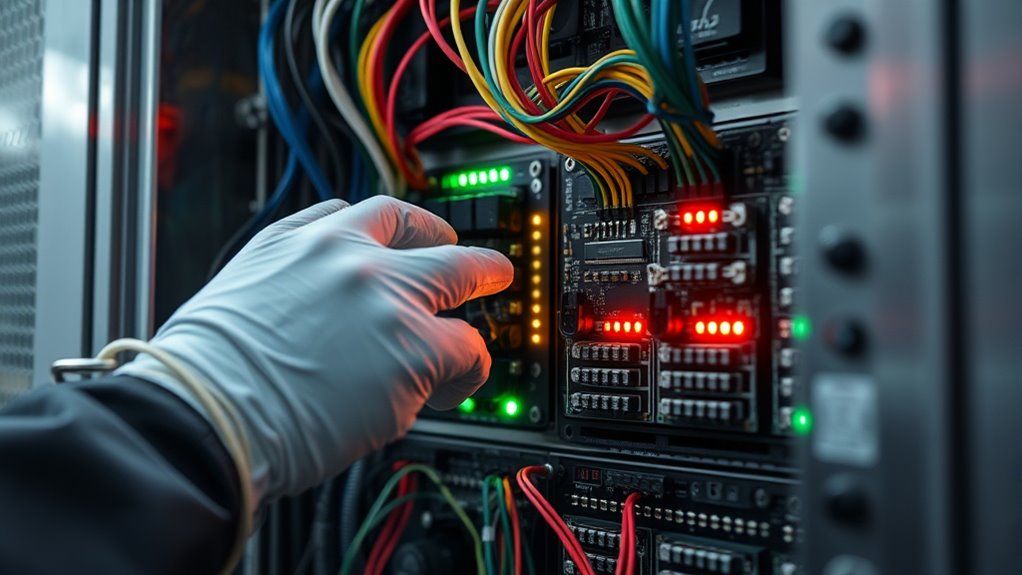

Preparing for a Safe Reset Procedure

Before initiating a reset, you should take several safety precautions to protect both yourself and the digital control unit. First, disconnect the power supply to prevent electrical shocks and damage. Making certain electrical safety is vital, so verify that no residual current remains before proceeding. Use proper troubleshooting techniques to identify any underlying issues that might affect the reset process. Wear insulated gloves and safety goggles to shield yourself from potential sparks or short circuits. Familiarize yourself with the control unit’s manual and safety guidelines. Clear the surrounding area of any conductive materials to avoid accidental shorts. Taking these precautions minimizes risks, guarantees a safe reset, and helps you troubleshoot effectively if problems persist afterward. Additionally, understanding the optimal angles for pinball machines can help maintain proper ball behavior during gameplay adjustments post-reset. Regularly inspecting appliances for power consumption issues can prevent future electrical problems. Remember, following proper safety procedures ensures both your safety and the longevity of the control unit. Moreover, consulting the all-waterpark features of related hospitality facilities can provide insights into comprehensive safety and maintenance practices.

Gathering Necessary Tools and Equipment

Before starting any work, you need to gather the essential tools and equipment to guarantee a smooth process. Make sure you have an accurate tool checklist, appropriate safety gear, and a well-prepared workspace. This preparation helps prevent accidents and keeps your project organized and efficient. Additionally, understanding the proper handling of electronic components can help avoid damage and ensure successful troubleshooting. Being aware of astrological influences on personal traits can also provide insight into how certain traits might affect your approach to technical tasks, fostering a more mindful work environment. Incorporating knowledge of essential oils for electronics or stress relief may also assist in maintaining focus and reducing anxiety during complex procedures. Moreover, familiarizing yourself with water-efficient toilet systems can inform better practices when working with related electronic control units. Furthermore, exploring common electrical component failures can prepare you to identify and address issues more effectively during the resetting process.

Essential Tool Checklist

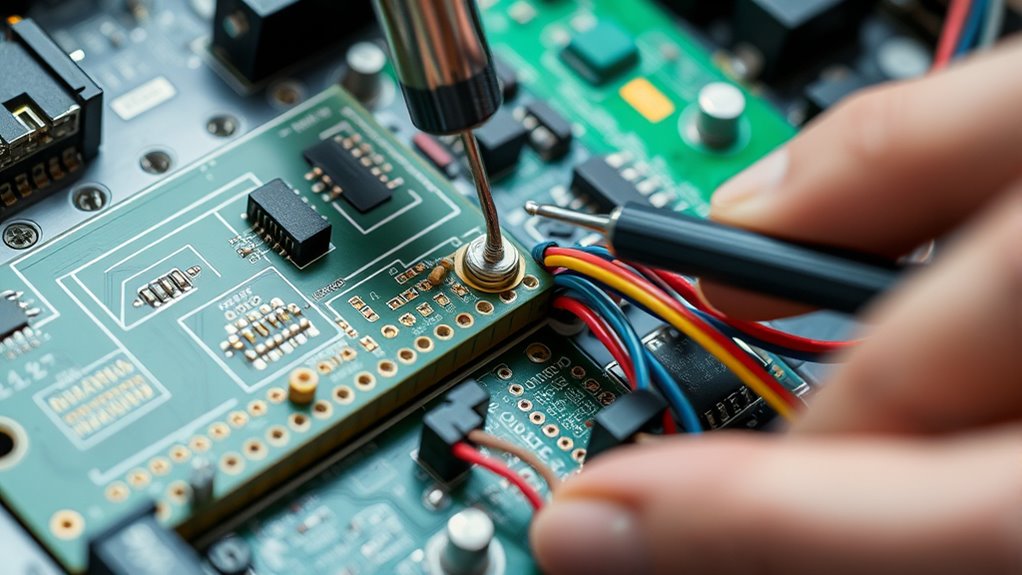

Gathering the right tools and equipment is essential for efficiently working on digital control units. Proper tools make circuit troubleshooting and component testing more accurate and safer. Here’s what you’ll need:

- Digital multimeter for precise voltage and resistance checks

- Screwdriver set for opening control units safely

- Anti-static wrist strap to prevent static damage

- Inspection flashlight for detailed visual assessments

- Non-contact voltage tester to identify live circuits quickly

- Familiarity with special occasions can also provide insight into how to celebrate milestones or mark important achievements in the process. Understanding electrical component functions can further improve troubleshooting accuracy and help in selecting appropriate replacements. Having a good grasp of cookie consent management can also assist in understanding how user consent impacts device operation and data handling.

Having these tools ready ensures you can diagnose issues effectively and reset electrical components without unnecessary delays. Focus on quality tools to improve accuracy during circuit troubleshooting and avoid damaging sensitive parts. Utilizing proper testing procedures can further enhance the safety and effectiveness of your work. It is also helpful to understand the electrical components involved, which can guide troubleshooting efforts and component replacements. By preparing your toolkit thoroughly, you streamline the process, reduce errors, and improve safety. This preparation lays the foundation for a smooth and successful component reset.

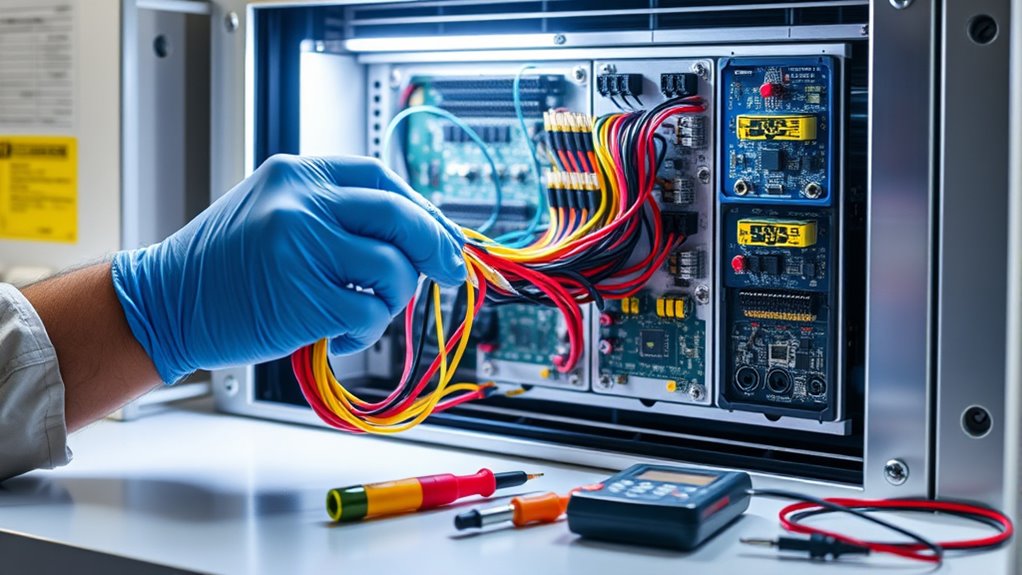

Proper Safety Gear

Equipping yourself with the right safety gear is essential to protect against electrical hazards when working on digital control units. Always wear protective gloves to prevent electric shocks and reduce the risk of accidental contact with live components. Insulated tools are critical, as they prevent current from passing through your body if you encounter energized parts. Ensure your gloves and tools are in good condition, free of tears or damage, to maintain their insulating properties. Before starting, double-check that all safety equipment fits properly and is rated for the voltage you’ll be handling. Remember, safety gear isn’t just a formality—it’s your first line of defense against injury. Proper safety gear allows you to work confidently and focus on the task, knowing you’re protected from electrical hazards. Additionally, understanding the types of headphone jacks can help prevent accidental damage or incorrect connections that might pose electrical risks.

Workspace Preparation

To work safely and efficiently on digital control units, you need to assemble all the necessary tools and equipment beforehand. Proper workspace preparation guarantees smooth procedures, especially when handling wireless communication or performing software updates. Gather essential items to minimize interruptions and risks. Keep your workspace organized and well-lit. Here are some key tools you’ll need:

- Screwdrivers and pliers

- Antistatic wrist strap

- Wireless communication device or module

- Computer with software update capabilities

- Multimeter for testing electrical connections

Having these tools ready allows you to focus on resetting components without delays. Ensuring your workspace is prepared helps prevent accidental damage and guarantees that software updates or wireless communication tasks proceed seamlessly, resulting in a safer, more efficient process.

Step-by-Step Guide to Powering Down the System

Before you begin powering down the system, make sure all ongoing processes are completed to prevent data loss or equipment damage. Check the status indicators to confirm no critical operations are running. Perform battery maintenance by inspecting terminals for corrosion and ensuring charge levels are adequate, as a faulty battery can cause power issues during shutdown. For circuit troubleshooting, identify any abnormal readings or signs of wear that could interfere with safe power-off. Turn off connected peripherals and note settings that may need reconfiguration afterward. Follow your system’s specific shutdown procedure, ensuring you do so gradually to avoid voltage spikes. Properly powering down safeguards your digital control unit, preserves data integrity, and prepares it for safe maintenance or resets.

Disconnecting and Reconnecting Power Sources

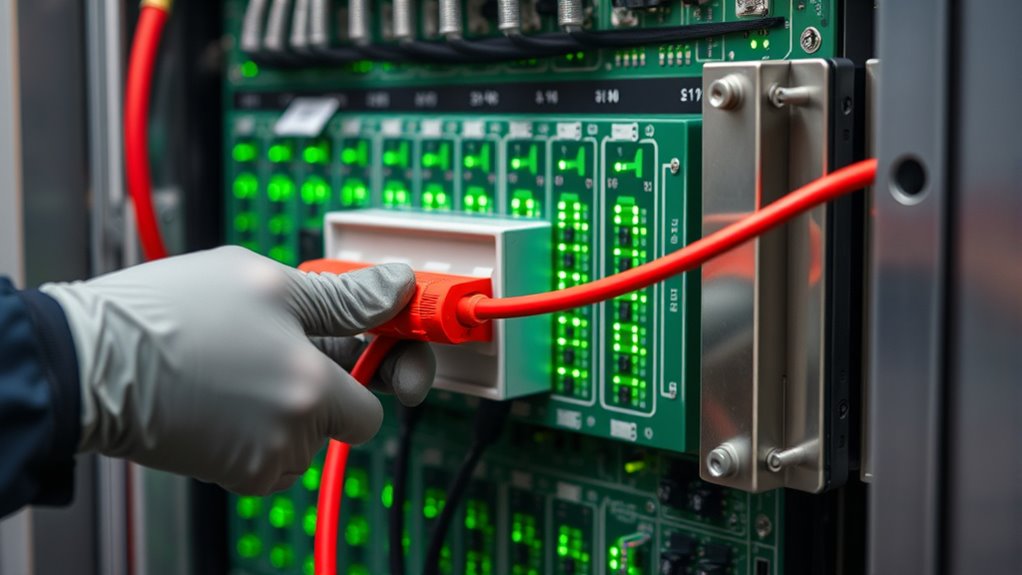

When disconnecting and reconnecting power sources, maintaining safety and system integrity is vital. You should always shut off the main circuit breaker before working on the control unit. Carefully locate the fuse box and check if a fuse replacement is needed to prevent electrical faults. Use insulated tools to avoid shocks, and verify that the power is fully disconnected before proceeding. Remember to inspect the circuit breaker for any signs of damage or wear. When reconnecting, ensure all connections are secure and the circuit breaker is reset properly. Double-check that no wires are loose or exposed. Properly managing these steps helps prevent short circuits, system failures, and guarantees safe handling of the electrical components.

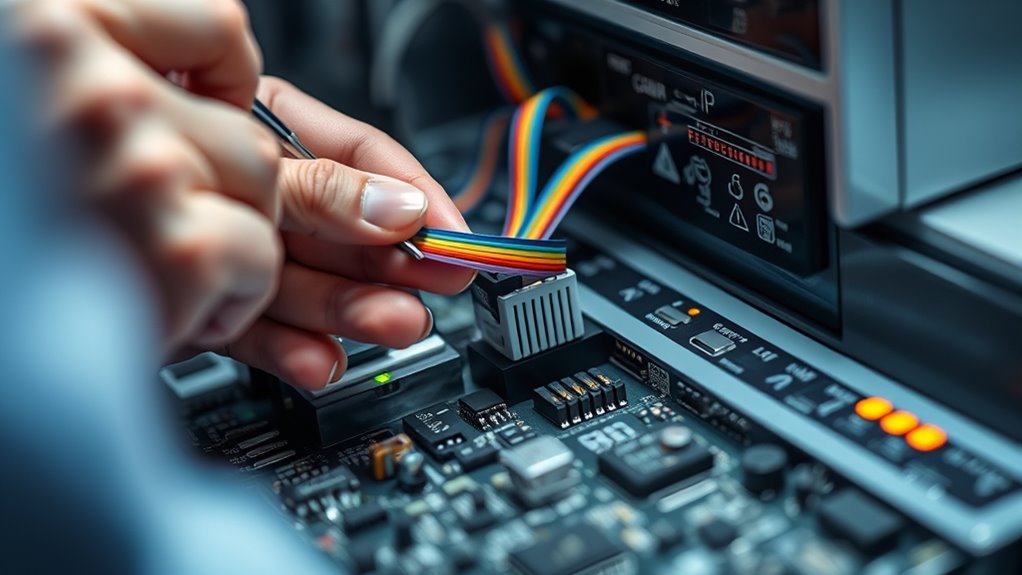

Performing a Manual Reset of the Control Unit

To perform a manual reset, you start by disconnecting the power source to guarantee safety. Next, you reconnect the power and watch for proper system responses. Finally, verify that the control unit operates correctly after the reset.

Power Disconnection Process

Performing a manual reset of the control unit involves a straightforward power disconnection process that clears any temporary faults or glitches. You should start by turning off the vehicle and locating the main power source to the digital control unit. Disconnecting power is essential for effective circuit troubleshooting and ensuring ideal battery maintenance.

- Identify the control unit’s power cable or fuse

- Use an insulated tool or gloves for safety

- Remove the power connection carefully

- Wait at least 30 seconds to allow residual charge to dissipate

- Reconnect the power, ensuring all connections are secure

This process resets the system, helping you diagnose issues and maintain battery health without risking further damage. Always follow safety protocols to avoid electrical shocks or damage during disconnection.

Reconnection and Verification

After ensuring the control unit has been disconnected and the residual charge has dissipated, reconnect the power supply carefully. Before powering up, perform circuit diagnostics to confirm all connections are secure. Once powered, verify the control unit’s operation by testing critical components. To streamline this, use the following checklist:

| Step | Action |

|---|---|

| Visual Inspection | Check for loose connections |

| Functional Testing | Verify component responses |

| System Monitoring | Observe for anomalies |

This process helps identify any issues early. If the system responds correctly, proceed with further component testing to ensure stability. Proper reconnection and verification prevent future faults and confirm the reset was successful. Always document your findings for future reference.

Verifying Successful Reset and System Functionality

How can you confirm that a reset was successful and the system is functioning properly? First, perform electrical diagnostics to ensure there are no fault codes or anomalies. Check for stable system responses and proper communication between components. Verify that system calibration has been restored to factory settings, guaranteeing ideal performance. Observe the control unit’s behavior during startup, looking for error messages or warning lights. Lastly, test key functions to confirm they operate as intended.

To confirm a successful reset, check for stable responses, clear fault codes, correct calibration, and proper function during startup.

- Smooth system boot without errors

- No lingering fault codes in diagnostics

- Correct calibration settings displayed

- Consistent electrical signals and responses

- Functional performance of critical features

Tips for Preventing Future Electrical Problems

Maintaining a system free of electrical issues starts with implementing proactive measures to prevent problems before they occur. One key tip is to regularly inspect and maintain electrical insulation, ensuring it remains intact and effective. Proper insulation prevents shorts and reduces wear on components. Additionally, practicing diligent circuit troubleshooting helps identify potential issues early, allowing you to address wiring faults or damaged components before they cause failures. Keep connections secure and avoid exposing wiring to moisture or extreme temperatures. Regularly clean and check control units to prevent dust buildup, which can lead to overheating. These steps, combined with understanding your system’s electrical layout, will help you avoid future electrical problems and extend the lifespan of your digital control units.

Frequently Asked Questions

Can Resetting Harm the Digital Control Unit or Other Connected Components?

You might wonder if resetting can cause electrical damage or component malfunction. If done improperly, it can indeed harm the digital control unit or connected parts by causing electrical surges or misconfigurations. Always follow manufacturer instructions carefully, use proper tools, and avoid abrupt resets. Properly resetting helps maintain functionality, but careless attempts can lead to electrical damage or malfunction, so proceed cautiously.

How Often Should Digital Control Units Be Reset for Optimal Performance?

You wonder how often you should reset your digital control units for peak performance. While there aren’t strict frequency guidelines, it’s best to reset during troubleshooting or if you notice glitches. Reset intervals depend on your device’s usage and manufacturer’s recommendations. Avoid excessive resets, as they can cause wear. Usually, resetting once in a while, when issues arise, helps maintain smooth operation without risking damage.

Are There Specific Safety Precautions for Resetting Units in Hazardous Environments?

When you’re working in a hazardous environment, safety precautions are vital before resetting units. You should wear appropriate protective gear, disconnect power sources, and verify that the area is safe. Make certain to follow all safety protocols specific to your environment, like using insulated tools and grounding equipment. Taking these steps helps prevent accidents and guarantees your safety during the reset process, reducing risks associated with hazardous conditions.

What Are the Signs That a Reset Is Not Resolving the Electrical Issue?

Think of your system like a ship steering stormy seas. If, after a reset, you notice persistent flickering lights or unresponsive controls, it’s a sign the storm isn’t over. Faulty wiring or power fluctuations could be to blame. These signs mean the issue isn’t resolved, and you should investigate further rather than assuming a simple reset fixed everything. Keep alert for these warning signals to avoid deeper damage.

Is Professional Assistance Necessary for Complex or Repeated Resets?

When facing complex or repeated resets, DIY troubleshooting might not be enough. You should consider professional assistance because resetting procedures can be intricate and risky if you’re unfamiliar with the system. A technician has the expertise to diagnose underlying issues and perform resets safely. Relying solely on resets without understanding the root cause can lead to more damage, so don’t hesitate to seek expert help for persistent problems.

Conclusion

So, now you’re a digital control unit reset pro—ready to tackle electrical snags with a flick of a switch. Just remember, if your system throws a tantrum again, it’s probably just craving your attention. Keep your tools handy, stay safe, and resist the urge to turn everything off mid-sentence. After all, nothing says “I’ve got this” like a well-timed reset, and maybe a little patience — or a good sense of humor.