Tip guard safety is all about protecting you from electrical shocks, slips, and injuries caused by accidental contact with sharp or live parts. Proper tip guards help prevent accidents by physically blocking access and ensuring tools work accurately and safely. Using tip guards not only keeps you safe but also improves your work quality and promotes a safety-first environment. To learn more about how to boost safety and protect yourself, keep going.

Key Takeaways

- Tip guard safety prevents accidental contact with live electrical parts, reducing injury risks to workers.

- Proper use and maintenance of tip guards ensure tools operate safely and effectively.

- Tip guards help maintain tool accuracy and stability, minimizing slips and accidents.

- Implementing tip guard safety demonstrates a commitment to regulatory compliance and workplace safety culture.

- Regular inspection and training on tip guard use promote responsible handling and accident prevention.

Understanding Tip Guard Safety: An Overview

Understanding Tip Guard Safety is essential because it directly affects your safety when working with electrical equipment. Proper safety training helps you recognize potential hazards and understand the importance of tip guards. These guards act as a first line of defense, preventing accidental contact with live parts. Developing hazard awareness is vital, as it enables you to identify risky situations before they cause injury. When you’re trained properly, you’re more likely to follow safety protocols and use tip guards correctly. This knowledge not only protects you but also reduces the risk of equipment damage and electrical fires. Inspirational quotes about fatherhood can serve as motivation to stay vigilant about safety practices. By prioritizing tip guard safety, you create a safer work environment and lower the chances of accidents occurring due to oversight or lack of awareness. Recognizing safety hazards is fundamental to maintaining a secure workspace and preventing potential injuries. Additionally, understanding regional bank hours can help ensure you plan your safety-related errands effectively, avoiding rushed situations at closing times. Being aware of exposure risks associated with electrical work emphasizes the importance of safety measures like tip guards to prevent serious injuries. Understanding hazard recognition enhances your ability to stay alert and respond promptly to dangerous situations.

How Tip Guards Function to Prevent Accidents

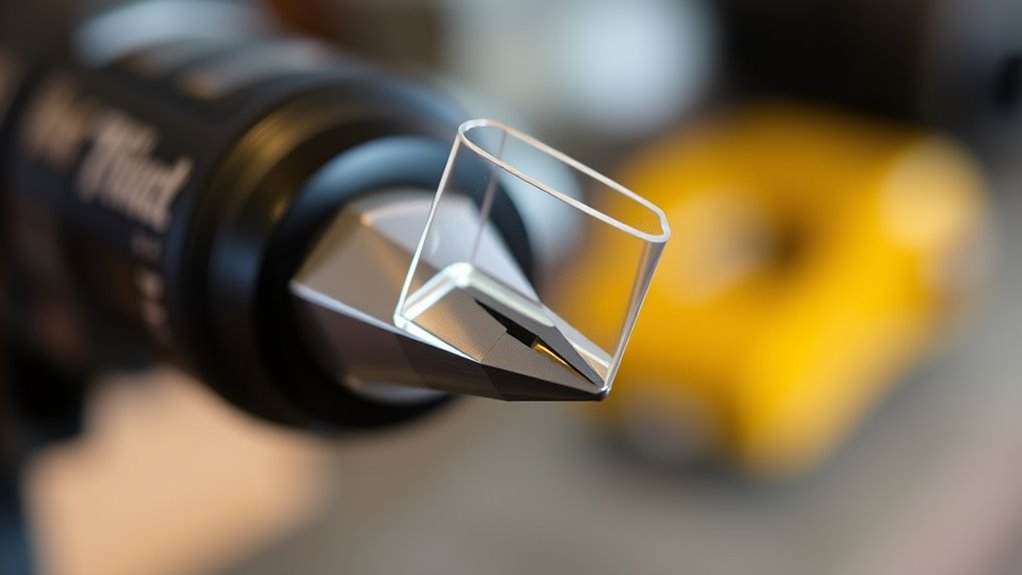

Tip guards work by physically blocking access to live electrical parts, preventing accidental contact that could cause shocks or injuries. They also ensure blade accuracy by maintaining proper positioning, reducing slips that might lead to accidents. Additionally, their ergonomic design helps you handle tools comfortably, minimizing fatigue and errors. A well-designed contrast ratio can also assist in visually identifying hazards, further enhancing safety. Proper tip guard design can also accommodate advanced safety features, providing an extra layer of protection in complex work environments. For example, integrating insulation materials can help prevent electrical conduction in case of damage, adding to overall safety. Here’s how they prevent accidents:

- Shielding: Covering exposed blades or contacts to prevent direct contact.

- Stabilizing: Keeping blades steady for precise cuts and safety.

- Guiding: Promoting proper tool handling to avoid slips.

- Comfort: Designing for ergonomic use, reducing strain and mistakes. Incorporating safety standards into tip guard design also helps prevent injury risks associated with mishandling tools.

Together, these features make tip guards essential for safe and accurate work, protecting you while enhancing performance.

Types of Tools and Equipment That Benefit From Tip Guards

You’ll find that power tools and cutting equipment greatly benefit from tip guards to prevent accidents. These safety features help protect you from unexpected injuries during operation. Incorporating tip guards is essential for maintaining safe working conditions with these tools. Additionally, Kia Tuning modifications often include safety considerations to ensure optimal performance without compromising vehicle safety. Proper maintenance and awareness of safety features such as tip guards can significantly reduce the risk of injury. Being familiar with environmental considerations can also contribute to safer and more responsible use of equipment. Moreover, understanding vehicle safety upgrades can further enhance overall safety during vehicle modifications.

Power Tool Safety

Power tools like saws, drills, and grinders pose significant safety risks if their tips or blades are exposed during use. Tip guards are essential to reduce injury by providing a physical barrier. To maximize safety and hazard awareness, consider these key tools:

- Circular saws—prevent accidental cuts during operation.

- Angle grinders—protect against sparks and flying debris.

- Drill bits—avoid contact with skin or eyes.

- Router bits—shield fingers from spinning blades.

Using tip guards improves safety, but don’t rely solely on equipment; always wear proper personal protective equipment. Maintaining awareness of hazards helps prevent accidents. Power tool safety emphasizes the importance of tip guards to minimize injury, especially when working with high-risk tools. Additionally, understanding the types of tools and safety features can help users select appropriate protective measures. Recognizing specific tuning and safety modifications in equipment can further enhance user protection and prevent malfunctions. Incorporating safety protocols into routine practices ensures a more comprehensive approach to workplace safety. For example, proper maintenance procedures can keep safety features like tip guards functioning effectively and reduce the likelihood of mechanical failure.

Cutting Equipment Protection

Many cutting tools and equipment benefit from tip guards to prevent injuries and guarantee safe operation. Tip guards help maintain proper blade alignment, reducing the risk of accidental contact. They are essential for tools like circular saws, jigsaws, and rotary cutters, where exposed blades pose safety concerns. Proper guard installation ensures the guard fits securely and functions effectively during use. When installed properly, tip guards provide a physical barrier that keeps your hands away from the blade’s tip, minimizing injury risk. Regularly check and adjust the guards to ensure they remain aligned with the blade. Additionally, understanding the Self Watering Plant Pots can provide insights into maintenance routines that ensure longevity and safety of your tools. Proper safety precautions and routine inspections are crucial in preventing accidents. Utilizing AI-powered safety tools can further enhance protective measures in your workspace. Being aware of relationships and how they can influence safety behaviors is crucial for fostering a safety-conscious environment. By using the right cutting equipment and maintaining proper tip guard installation, you enhance safety and improve the overall efficiency of your work. Incorporating comprehensive safety protocols ensures consistent protective practices on the job site.

The Importance of Incorporating Tip Guards Into Safety Protocols

Incorporating tip guards into safety protocols is essential because they serve as a crucial barrier against accidental injuries. They enhance material handling by preventing slips or punctures during work. Consider these reasons:

- Protects workers from sharp tools, reducing the risk of cuts.

- Improves workplace ergonomics by minimizing awkward movements to avoid injury.

- Ensures compliance with safety regulations, avoiding penalties.

- Promotes a safety-first culture, encouraging responsible behavior.

Tip guards are a simple yet effective way to integrate safety into daily operations. By embedding them into your protocols, you help reduce accidents, protect your team, and create a safer work environment. Prioritizing safety measures like tip guards demonstrates your commitment to worker well-being and operational efficiency.

Benefits of Using Tip Guard Safety for Workers and Employers

Using tip guard safety offers direct benefits for both workers and employers by reducing injury risks and boosting efficiency. Proper workplace ergonomics minimizes strain and discomfort, helping you work more comfortably and safely. When employees receive thorough training, they better understand how to use tip guards correctly, preventing accidents. This safety measure also streamlines operations by reducing downtime caused by injuries. Consider this table:

| Benefit | How It Helps | Impact |

|---|---|---|

| Reduced injuries | Protects hands and fingers | Fewer sick days |

| Improved workplace ergonomics | Less strain during tasks | Greater productivity |

| Enhanced employee training | Better safety habits | Safer environment |

Best Practices for Maintaining and Using Tip Guards Effectively

To guarantee tip guards provide maximum protection, it’s essential to follow best practices for their maintenance and use. First, regularly inspect the tip guards for damage or wear, replacing them if necessary. Second, ensure proper tool maintenance by keeping equipment clean and well-maintained to prevent malfunctions. Third, provide detailed employee training, emphasizing correct installation, use, and inspection procedures. Fourth, document maintenance routines and inspections to track compliance and identify recurring issues. Keeping tip guards in top condition requires consistent attention and up-to-date training, which reduces accidents and enhances safety. By adhering to these best practices, you guarantee tool maintenance is effective and that employees understand how to use tip guards correctly, creating a safer work environment overall.

Frequently Asked Questions

Are Tip Guards Legally Mandated for All Power Tools?

You might wonder if tip guards are legally required for all power tools. While safety regulations vary by region, many jurisdictions mandate tip guards to reduce injury risks. Proper tool maintenance includes ensuring guards are in place and functional. Always check local safety regulations and manufacturer guidelines to comply with laws and keep yourself safe. Using tip guards properly is a key part of maintaining safe work practices and preventing accidents.

How Often Should Tip Guards Be Inspected for Safety?

Imagine the smooth hum of your workspace, and you realize tip guards need regular inspection to keep it that way. You should check them at least monthly, following your maintenance protocols, to make sure they’re intact and functioning properly. Regular inspection frequency helps prevent accidents, keeps your tools safe, and maintains efficiency. By staying vigilant and consistent, you’re protecting yourself and others, making safety a natural part of your routine.

Can Improper Tip Guard Installation Compromise Safety?

Improper tip guard installation can seriously compromise safety, making tool maintenance and following safety protocols essential. If you don’t install it correctly, the guard might not protect you from moving parts or debris, increasing injury risk. Always double-check that the tip guard is securely installed and in good condition before use. This guarantees you follow safety protocols and minimizes accidents, keeping your workspace safe and compliant.

Are There Specific Training Requirements for Tip Guard Use?

You should know that training standards for tip guard use are essential to guarantee safety. Proper training helps you understand how to install, inspect, and maintain tip guards correctly. Many workplaces require safety certification to verify your knowledge and skills. By completing these training requirements, you reduce the risk of accidents and protect yourself and others. Always follow your employer’s guidelines and stay updated on any new safety protocols related to tip guard use.

What Are Common Signs of Tip Guard Failure?

You should watch for signs of tip guard failure, such as sharp blades becoming exposed or loose fittings around the guard. If the guard is damaged or doesn’t fit securely, it might not protect you properly. Always inspect the tip guard before use, guaranteeing it’s firmly in place and free from cracks or wear. Address any issues immediately to prevent accidents and ensure safe operation of your equipment.

Conclusion

By embracing tip guard safety, you’re planting a sturdy shield around your workspace—a silent guardian that guards lives like a lighthouse guiding ships through storms. When you prioritize these safeguards, you’re not just preventing accidents; you’re building a legacy of care and responsibility. Remember, every tip guard is a beacon of safety, illuminating the path toward a safer, more confident future for you and your team.