If your motor won’t start, first check the power supply, circuit breaker, and wiring connections for any faults or loose wires. Use a multimeter to verify voltage at the motor terminals and ensure safety switches are not preventing operation. If these checks are okay but it still won’t run, inspect internal components or mechanical parts like bearings and brushes. Continuing with these steps will help you pinpoint the exact cause and find the right solution.

Key Takeaways

- Verify power supply and circuit connections using a multimeter for proper voltage delivery.

- Check for blown fuses, loose wiring, or faulty switches that may interrupt power flow.

- Inspect motor components like brushes and bearings for mechanical issues or obstructions.

- Test internal motor windings and insulation for damage if electrical supply is confirmed.

- Ensure external safety interlocks and control systems are not preventing motor startup.

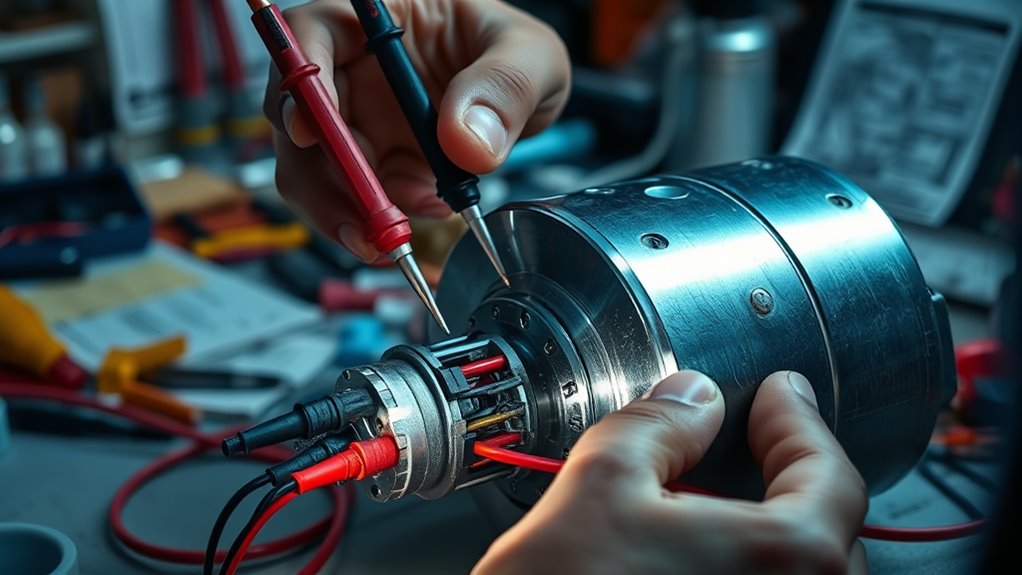

When your motor refuses to start, it can be frustrating and disruptive. You rely on your equipment to keep things running smoothly, and a non-starting motor stalls progress. The first step is to diagnose the problem accurately. Often, issues stem from electrical faults, so circuit testing becomes essential. Start by inspecting the power supply—ensure the outlet is functioning properly, and check that the circuit breaker hasn’t tripped. If the power source is fine, move on to testing the circuit wiring. Look for loose connections, damaged wires, or blown fuses that could interrupt current flow. Use a multimeter to perform circuit testing, verifying that voltage reaches the motor terminals. If you find no power at the motor, the problem likely isn’t with the motor itself but with the electrical circuit feeding it.

Once you confirm the circuit is delivering proper voltage, but the motor still won’t start, you may need to contemplate the motor’s internal condition. Mechanical issues such as seized bearings or worn brushes can prevent startup, but electrical faults are more common causes. If circuit testing shows everything is in order, and the motor still doesn’t respond, it might be time to replace the motor. Motor replacement is often the most straightforward solution when internal components are damaged beyond repair or if troubleshooting indicates a complete failure. Keep in mind that before replacing the motor, double-check the wiring connections, ensure the motor is receiving the correct voltage, and confirm there are no external obstructions or safety switches preventing operation. Additionally, understanding the contrast ratio of your motor’s components can help diagnose if insufficient contrast is affecting performance, especially in specialized applications.

When replacing the motor, make sure you select a compatible model and follow proper safety procedures. Disconnect power before removing the faulty motor, then carefully disconnect any wiring or mounting brackets. Install the new motor according to the manufacturer’s instructions, ensuring all connections are secure and correctly insulated. After installation, perform circuit testing again to confirm proper voltage and operation. Power up the system and observe whether the motor starts smoothly. If it still doesn’t start, recheck all connections, verify the new motor’s compatibility, and consider consulting a professional if problems persist. Remember, motor replacement can be a quick fix, but only if the root cause isn’t linked to the electrical circuit or control system. Proper diagnosis and careful installation are key to restoring your equipment’s functionality efficiently.

Frequently Asked Questions

Can a Faulty Relay Prevent a Motor From Starting?

Yes, a faulty relay can prevent your motor from starting. Relay failure disrupts the electrical connection needed for the motor to run, stopping power flow. Additionally, a power surge can damage the relay, causing it to malfunction. If you notice your motor won’t start, check the relay for signs of failure or damage from a power surge. Replacing a faulty relay often resolves the issue and gets your motor running again.

How Does Ambient Temperature Affect Motor Startup?

Ambient temperature acts like an invisible hand shaping your motor’s dance at startup. When it’s cold, the motor startup becomes sluggish, as thickened lubricants and stiffened components resist motion. Conversely, warm temperatures allow smoother initiation, easing the motor into action. So, you’ll find that ambient temperature influences how easily your motor begins to turn, with colder environments demanding patience and warmer ones inviting a swift, effortless startup.

What Role Does Motor Size Play in Troubleshooting?

Motor size plays a vital role in troubleshooting because motor capacity and size considerations directly impact startup issues. A larger motor requires more power, so if it’s undersized or overloaded, it may struggle to start. Check if your motor’s size matches the application’s demands. Ensuring proper sizing helps prevent overloading, reduces stress on components, and makes troubleshooting more straightforward by focusing on capacity-related problems first.

Can Wiring Color Codes Cause Startup Issues?

Wiring color codes can definitely cause startup issues if you get them mixed up—it’s like trying to solve a puzzle with missing pieces. Your wiring color, such as black for hot or white for neutral, guides proper connections. Misreading these color codes can lead to incorrect wiring, causing the motor to not start or even be unsafe. Always double-check the wiring color codes to make certain of a safe, smooth startup.

Is It Necessary to Reset Circuit Breakers Regularly?

Yes, you should reset circuit breakers only when necessary, not regularly. Proper circuit breaker maintenance involves inspecting for damage or wear and making sure they trip correctly to protect your electrical system. Following electrical safety procedures is essential; always turn off power before resetting or inspecting breakers. Regular checks help prevent electrical hazards and ensure your system functions properly, but unnecessary resets can cause wear or mask underlying issues.

Conclusion

Remember, troubleshooting your motor is like solving a mystery—you just need to follow the clues. Check your connections, inspect the power source, and listen for any unusual sounds. With patience and a keen eye, you’ll uncover the culprit behind the no-start issue. Don’t let frustration stall your progress; instead, see it as an adventure in problem-solving. After all, every mystery has a solution waiting to be found—your motor’s just waiting for you to crack the case.