When comparing aftermarket versus OEM sprayer accessories, you should consider quality, fit, and durability. OEM parts come from the original manufacturer, ensuring better compatibility and longer-lasting performance, though they often cost more. Aftermarket parts are typically cheaper and more flexible but may vary in quality and fit, risking leaks or damage. To make the best choice for your equipment, understanding these differences can help you save money and improve reliability over time. Keep exploring to learn more.

Key Takeaways

- OEM accessories guarantee precise fit, consistent quality, and better compatibility, reducing leaks and operational issues.

- Aftermarket parts often cost less initially but may compromise durability and long-term performance.

- OEM options typically adhere to strict standards, offering superior corrosion resistance and longer lifespan.

- Aftermarket accessories provide a wider variety of options and easier availability but may vary in quality.

- Investing in OEM parts can lower long-term maintenance costs due to higher durability and reliable support.

Understanding the Differences Between OEM and Aftermarket Accessories

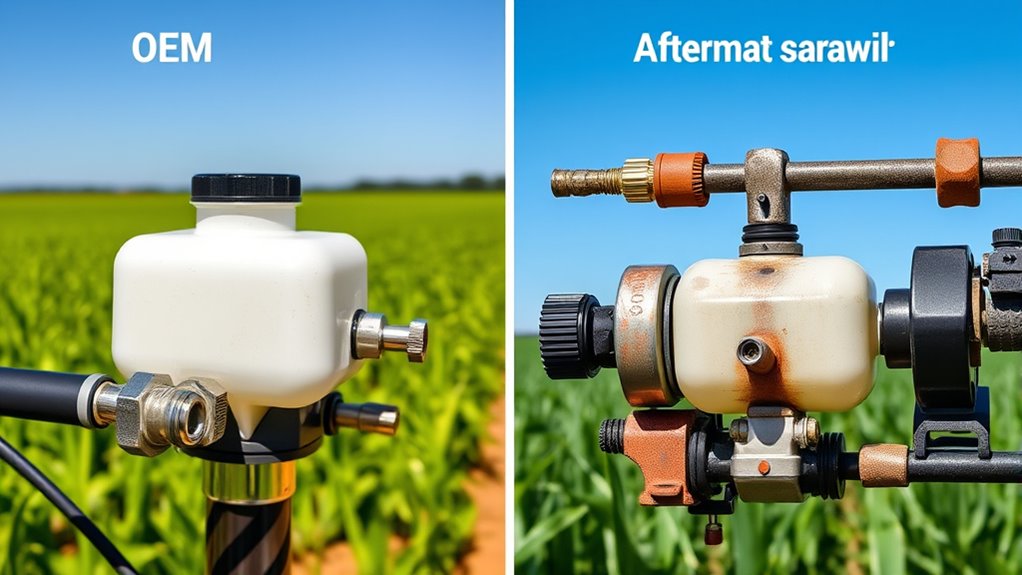

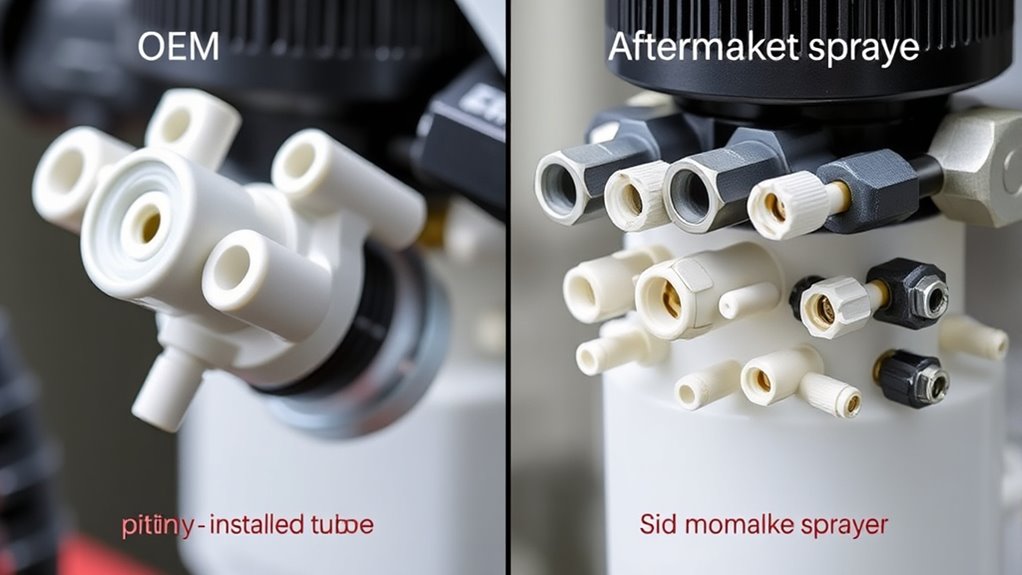

When choosing sprayer accessories, understanding the key differences between OEM and aftermarket options is essential. Brand reputation plays a big role; OEM parts are made by the original manufacturer, ensuring consistent quality and trustworthiness. Aftermarket accessories, however, come from third-party brands, which can vary widely in reputation. Aesthetic appeal also differs—OEM parts often match the original design seamlessly, maintaining a uniform look. Aftermarket options might offer more variety or unique styles, but they may not always blend perfectly with your equipment. Recognizing these differences helps you make informed decisions based on your priorities for brand reliability and visual consistency. Additionally, understanding product differentiation can assist in selecting accessories that meet your specific needs and preferences. Considering performance standards is also important, as OEM parts typically adhere to strict specifications, whereas aftermarket parts may have varying quality levels. Being aware of compatibility issues can prevent mismatched components and ensure optimal functioning. Moreover, evaluating the resources and training behind different accessories can help determine their long-term reliability and the support available if issues arise. Recognizing the importance of regulatory compliance can also influence your choice, especially when specific safety or environmental standards are required.

Quality and Durability Considerations

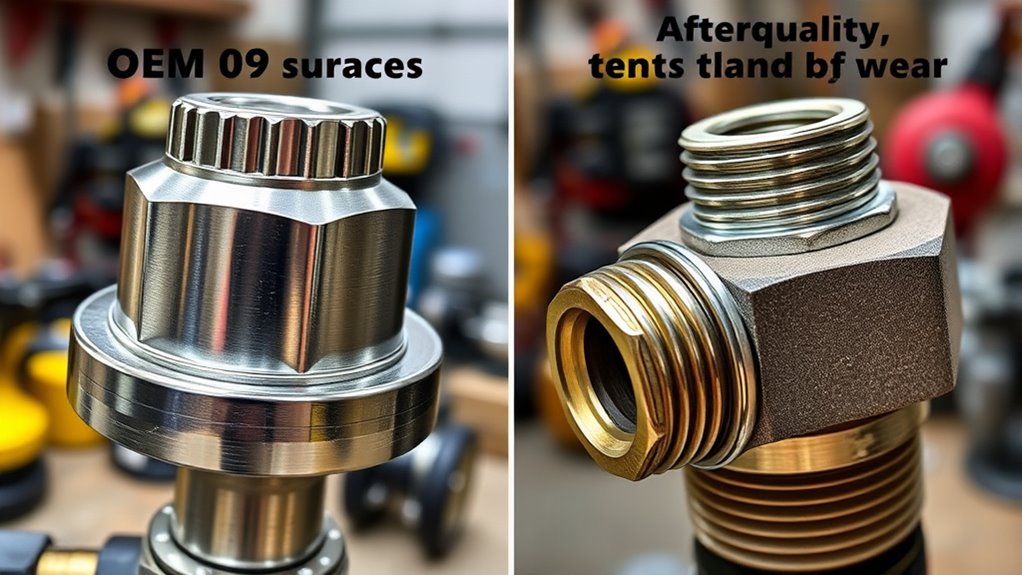

The quality and durability of sprayer accessories directly impact their performance and lifespan. Material composition is vital; high-quality materials like durable plastics or metals resist wear and corrosion better. OEM accessories often adhere to strict manufacturing standards, guaranteeing consistent quality and reliable performance over time. Aftermarket options can vary considerably in material quality, which may affect their longevity. Poorly manufactured accessories might crack, leak, or break sooner, leading to increased costs and downtime. When choosing between aftermarket and OEM, consider how manufacturing standards influence durability. Well-made accessories, regardless of origin, should withstand regular use and exposure to chemicals or weather. Material quality is a key factor to evaluate when assessing accessory durability, as it determines resistance to environmental stressors and chemical exposure. Additionally, understanding the manufacturing standards behind these accessories can help ensure you select options that will stand up to demanding conditions, providing better value over time. Ensuring proper quality control during manufacturing can significantly reduce the risk of defects or failures, making it a crucial aspect of durability. Paying attention to testing procedures and certifications can also give you confidence in the long-term performance of the accessories. Implementing rigorous quality assurance processes further enhances the reliability and durability of these accessories, ultimately extending their service life. Prioritizing quality ensures your sprayer functions efficiently longer, saving you money and hassle in the long run.

Cost and Budget Implications

Choosing between aftermarket and OEM sprayer accessories often comes down to cost and budget considerations. With aftermarket options, you might find lower prices due to aggressive pricing strategies, making them attractive if you’re looking to save money upfront. However, these cheaper options can sometimes compromise on quality, which could lead to higher costs over time. OEM accessories, on the other hand, tend to have higher prices reflecting their brand reputation for reliability and performance. While they may require a larger initial investment, their proven durability can save you money in the long run by reducing replacements and repairs. Additionally, OEM parts often meet stricter quality standards, providing better performance and peace of mind. When considering durability and compatibility, OEM options are often seen as the more reliable choice. Moreover, understanding product standards can help you make more informed decisions about which accessories will meet your long-term needs. Recognizing the importance of quality assurance can guide you to select options that ensure consistent operation and safety. In the context of long-term reliability, OEM parts are generally preferred for their consistent quality and dependable operation. Ultimately, your decision should balance your budget constraints with the importance of long-term reliability, keeping in mind how brand reputation influences pricing strategies.

Compatibility and Fitment Issues

Compatibility and fitment issues can substantially impact your sprayer’s performance, especially if you opt for aftermarket accessories. If the parts don’t fit properly, you may face leaks, uneven spray patterns, or equipment damage. Paint compatibility is vital; some aftermarket accessories may not work well with certain paint types, leading to clogging or poor application. Color matching is also important, especially if you need consistent results across multiple projects. OEM accessories are designed specifically for your sprayer model, ensuring proper fit and compatibility. In contrast, aftermarket parts might require modifications or adjustments, increasing the risk of misfit and operational issues. Always verify compatibility and fitment details before purchasing to avoid these problems and ensure your sprayer functions efficiently. Additionally, understanding compatibility issues can help prevent costly repairs and ensure optimal performance of your equipment. Being aware of essential oils and their proper usage can also improve the longevity and safety of your sprayer, especially when working with chemical-based products.

Impact on Equipment Performance

Using aftermarket sprayer accessories can considerably influence your equipment’s performance, sometimes in unpredictable ways. Poorly designed parts may disrupt sprayer calibration, leading to uneven application and waste. Chemical compatibility is also critical; incompatible accessories can cause corrosion or clogging, reducing efficiency. To illustrate, consider the following:

| Accessory Type | Impact on Calibration | Chemical Compatibility |

|---|---|---|

| OEM nozzle | Precise application | Fully compatible |

| Aftermarket nozzle | Calibration may vary | Potential for clogging |

| Pump components | Consistent flow | Varies by material |

| Spray tips | Impact on spray pattern | Limited testing |

| Filters | Protects internal parts | Compatibility issues |

Choosing the right accessory affects your equipment’s accuracy and longevity. Additionally, selecting proper materials for accessories can enhance durability and chemical resistance, ensuring better performance over time. When selecting components, considering compatibility with existing parts is essential to prevent issues and maintain optimal operation. Moreover, understanding industry standards can help in choosing accessories that meet safety and quality benchmarks, prolonging equipment life. Recognizing the importance of cybersecurity vulnerabilities, such as those highlighted during major outages, can also influence how digital components and remote monitoring systems are integrated into maintenance practices.

Warranty and Support Services

When it comes to aftermarket sprayer accessories, warranty and support services play a crucial role in protecting your investment. With aftermarket parts, warranty claims can be more complicated, often involving third-party manufacturers who may have different policies. It’s essential to understand whether the product comes with a clear warranty and how easy it is to make claims if issues arise. Customer service quality also varies widely; some brands offer responsive, helpful support, while others may leave you waiting or with unresolved problems. OEM accessories typically provide more straightforward warranty claims and dedicated support because they’re backed by the original manufacturer. This reliable support can save you time and hassle, giving you peace of mind that your investment is protected. Warranty policies are an important factor to consider when choosing between aftermarket and OEM sprayer accessories. Additionally, understanding the support infrastructure of the manufacturer can help ensure you receive timely assistance when needed.

Availability and Selection Options

Aftermarket sprayer accessories often offer a wider range of options, giving you more choices to customize your equipment. With greater product variety, you can find accessories tailored to specific needs or preferences, enhancing your sprayer’s performance. These options are usually supported by extensive supplier networks, making it easier to locate and purchase the parts you want. Unlike OEM accessories, which may be limited to manufacturer-specific items, aftermarket products often come from multiple suppliers, increasing availability. This broader selection allows you to compare features, prices, and compatibility more easily. As a result, you gain flexibility and control over your equipment’s setup, ensuring you can optimize your sprayer for various tasks and conditions without being restricted to a narrow set of options.

Long-term Maintenance and Replacement Factors

When considering long-term maintenance, it’s important to think about how durable and wear-resistant the accessories are. You’ll also want to compare how often you’ll need replacements and what those costs look like. Finally, check if the accessories are compatible with your sprayer and if they can be upgraded over time.

Durability and Wear Resistance

Durability and wear resistance are essential factors to contemplate because they directly impact how long your sprayer accessories last and how often you’ll need to replace them. High-quality OEM parts often excel in chemical resistance, helping them withstand harsh solutions without degrading. They also typically offer better corrosion protection, which is critical for longevity, especially in humid or corrosive environments. Aftermarket accessories can vary widely in durability; some may lack the same level of chemical resistance or corrosion protection, leading to faster wear and tear. Choosing accessories with superior durability ensures your sprayer remains functional longer and reduces downtime. Ultimately, investing in durable, wear-resistant parts saves you money and effort in the long run by decreasing the frequency of replacements and maintenance.

Replacement Frequency and Costs

Since durability impacts how often accessories need replacing, considering replacement frequency and costs is essential for managing long-term maintenance. OEM accessories often have a higher initial price due to strict manufacturing standards, but their durability can lead to less frequent replacements, lowering overall costs. Aftermarket options may use different pricing strategies, sometimes offering lower upfront costs, but they might wear out faster, increasing replacement frequency and expenses over time. The manufacturer’s reputation also plays a role; reputable brands tend to produce more reliable parts, reducing the need for frequent replacements. When evaluating options, weigh the long-term costs against initial investment. Ultimately, choosing accessories based on durability, pricing strategies, and the manufacturer’s reputation helps you better manage maintenance costs over the lifespan of your sprayer system.

Compatibility and Upgradeability

Compatibility and upgradeability are crucial factors to ponder because they directly affect your long-term maintenance and replacement needs. With aftermarket accessories, you might find options that don’t match your sprayer’s paint color or branding logos, making them less seamless visually. OEM parts are designed specifically for your equipment, ensuring perfect compatibility and the ability to upgrade components as technology advances. This means you can update your sprayer’s features without worrying about mismatched paint colors or logos that don’t align. Upgrading OEM accessories is usually straightforward, preserving your equipment’s appearance and branding consistency. In contrast, aftermarket options may require additional modifications, possibly affecting the overall look and ease of future upgrades. Ultimately, compatibility and upgradeability influence your equipment’s longevity and professional appearance.

Frequently Asked Questions

How Do Aftermarket Accessories Affect the Resale Value of Equipment?

When considering how accessories impact your equipment’s resale value, you should know that aftermarket options can sometimes boost appeal, but they may also affect equipment depreciation negatively if they’re low quality or not popular. Buyers often prefer OEM parts for reliability, which can help maintain resale value. Ultimately, high-quality aftermarket accessories might enhance your equipment’s functionality and attractiveness, but poorly chosen ones could reduce its resale value over time.

Are There Any Safety Concerns With Aftermarket Sprayer Accessories?

Think of installing aftermarket sprayer accessories like adding new gear to a trusted tool—you want it to work safely. You should carefully check installation safety and guarantee they meet regulatory compliance, just like following a recipe precisely. If these aren’t followed, safety concerns can arise, risking accidents or damage. Always verify that aftermarket accessories are compatible and certified to keep your equipment safe and compliant with industry standards.

Can OEM Accessories Be Customized for Specific Spraying Needs?

You can customize OEM accessories to fit your specific spraying needs, offering tailored solutions for your equipment. However, be aware of potential compatibility challenges, as OEM parts are designed for particular models. It is crucial to verify customization options with the manufacturer to ensure proper fit and function. This way, you get the benefits of personalization while minimizing issues related to compatibility. Always consult experts before making modifications.

What Is the Average Lifespan Difference Between OEM and Aftermarket Parts?

You might notice that OEM parts generally have a longer lifespan due to their durability comparison, often lasting 1-3 years with proper maintenance. They typically come with better warranty coverage, offering peace of mind. Aftermarket parts can be cheaper and may last less, around 6 months to 2 years, but their durability varies widely. Your choice depends on your budget and how long you need the parts to perform reliably.

How Do Local Regulations Influence Accessory Choices for Sprayers?

You should consider local regulations when choosing sprayer accessories, as they influence what’s legally compliant and safe. Regulations often require accessory compliance with safety standards, environmental restrictions, and industry standards. Ignoring these rules could lead to fines or equipment issues. Always check local laws before selecting accessories to guarantee they meet the necessary compliance, helping you avoid legal problems and maintain efficient, safe sprayer operation.

Conclusion

Choosing between OEM and aftermarket sprayer accessories might seem straightforward, but sometimes the best option reveals itself unexpectedly. You might find that a budget-friendly aftermarket part outperforms an OEM component, or a rare OEM piece perfectly fits a unique need. Ultimately, weighing quality, compatibility, and cost can lead to surprising solutions that keep your equipment running smoothly. Sometimes, the right choice comes when you least expect it—reminding you that the best fit isn’t always the most obvious one.