To keep your airless sprayer in top shape, establish a regular maintenance schedule. Daily, check for clogs, clean filters, and inspect parts for leaks. Weekly, verify paint compatibility and calibrate the system. Monthly, perform system checks, clean nozzles, and guarantee proper operation. Seasonally, deep clean, inspect hoses, and prepare for storage. Proper storage in a cool, dry environment minimizes damage and extends your equipment’s life—learn more to keep it running smoothly.

Key Takeaways

- Perform daily inspections and clean spray tips, filters, and connections to prevent clogs and ensure consistent spray patterns.

- Conduct weekly checks of hoses, seals, and lubrication to detect wear and maintain optimal system performance.

- Schedule monthly system tests, calibrations, and component replacements to prevent issues and ensure proper operation.

- Carry out seasonal deep cleaning and thorough inspections to remove residual paint and prepare equipment for storage.

- Store your sprayer in a cool, dry, well-ventilated environment with protective coverings to extend lifespan and maintain readiness.

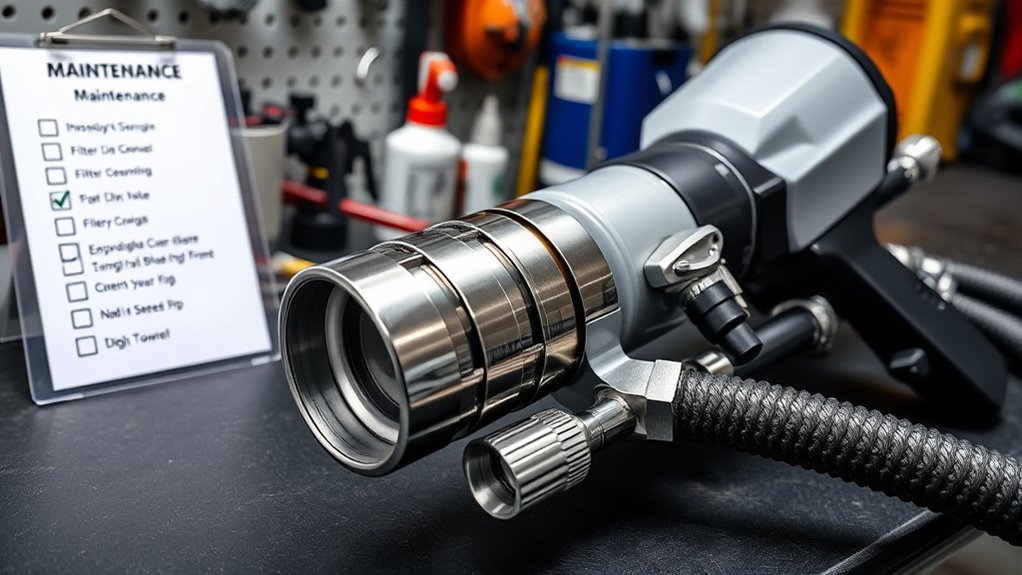

Daily Inspection and Cleaning

To guarantee your airless sprayer operates smoothly and lasts longer, you should perform a daily inspection and cleaning. Begin by checking paint compatibility to ensure you’re using the right type for your sprayer, preventing clogs or damage. Next, examine the spray pattern; a consistent pattern indicates proper operation, while irregularities suggest issues needing attention. Clean the spray tip and filters thoroughly to remove residual paint, which can affect spray quality. Wipe down the exterior to prevent dust buildup. Make sure all connections are tight and free from leaks. Regular cleaning and inspections help maintain ideal spray performance, reduce downtime, and extend the lifespan of your equipment. Staying vigilant daily ensures your sprayer functions reliably and produces a professional finish. Incorporating routine maintenance into your schedule can further optimize performance and prevent costly repairs.

Weekly Maintenance Tasks

Each week, you should clean the spray nozzle to prevent clogs and guarantee smooth operation. It’s also important to check fluid levels and top off as needed to avoid interruptions during your project. Taking these steps keeps your sprayer working efficiently and extends its lifespan. Additionally, inspecting the gasket seals can help prevent leaks and maintain optimal pressure during use.

Clean Spray Nozzle

Regularly cleaning the spray nozzle is essential for maintaining ideal spray quality and preventing clogs. When you clean the nozzle, check the nozzle alignment to ensure it’s properly positioned for an even spray pattern. Misalignment can cause uneven coverage and affect finish quality. Use a soft brush or a nozzle cleaner to remove paint residue and debris, paying close attention to the orifice. Clear any obstructions that might distort the spray pattern. Consistent cleaning helps maintain consistent spray performance and prevents buildup that could cause irregular spray patterns or clogging. After cleaning, inspect the nozzle for damage or wear, replacing it if necessary. Keeping your spray nozzle clean ensures your equipment operates smoothly and your finishes remain professional. Additionally, understanding paint viscosity and how it affects spray performance can help you choose the right nozzle size and pressure settings for optimal results.

Check Fluid Levels

Have you checked your fluid levels lately? Regularly inspecting fluid levels ensures your sprayer operates smoothly. Proper fluid calibration is essential to maintain accurate spray patterns and prevent uneven coating. If fluid levels are low, top off with the manufacturer-recommended materials to avoid damage and inconsistent application. While checking, also verify that all components are properly lubricated—this helps prevent wear and prolongs equipment life. Maintaining correct fluid levels and lubrication routines minimizes downtime and ensures your sprayer functions efficiently during each use. Regularly reviewing necessary cookies and other site components can also help you stay informed about equipment maintenance tips. Make this a weekly habit to keep your equipment in top shape and avoid costly repairs.

Monthly System Checks

To keep your airless sprayer operating efficiently, it’s necessary to perform monthly system checks. Begin by inspecting paint compatibility to ensure you’re using the right type for your equipment, which prevents clogs and damage. Check safety equipment such as gloves, masks, and goggles to confirm they’re in good condition and ready for use. Examine hoses and fittings for leaks, wear, or cracks, replacing any damaged parts immediately. Clean the filter and screens to maintain proper flow and prevent debris from entering the system. Test the pressure relief valve to ensure it functions correctly for safety. Additionally, verify that the spray gun operates smoothly and that all connections are secure. Regularly conducting these checks helps prevent breakdowns and keeps your sprayer running at peak performance. Preventative maintenance is also key to extending the lifespan of your equipment and avoiding costly repairs.

Seasonal Deep Cleaning and Inspection

Seasonal deep cleaning and inspection are essential to maintain your airless sprayer’s performance throughout the year. During this process, clean all components thoroughly to remove paint residue, guaranteeing paint compatibility for your next project. Check hoses, filters, and nozzles for clogs or wear, replacing parts as needed. Inspect seals and fittings to prevent leaks, and verify that the pressure system functions correctly. Don’t forget to review your safety equipment—gloves, masks, and goggles—to ensure they’re in good condition before use. Proper cleaning prevents buildup that can cause uneven spray patterns or equipment damage. Regular inspections also help you catch potential issues early, extending the lifespan of your sprayer and maintaining ideal performance for any seasonal project. Developing a maintenance schedule ensures consistent care and optimal operation year-round.

Troubleshooting Common Issues

When your airless sprayer isn’t performing as expected, identifying the root cause can save you time and frustration. If you notice uneven spray patterns or inconsistent coating, check your airless sprayer calibration first. Proper calibration ensures the spray pressure and flow rate are correct, which is crucial for powder coating applications. Clogged nozzles or filters can also cause interruptions; clean or replace them as needed. If you’re experiencing paint sputtering or excessive overspray, inspect the tips and seals for wear and tear. Sometimes, issues stem from incorrect pressure settings or contaminated fluid. Regularly troubleshooting these common issues helps maintain peak performance and extends your equipment’s lifespan. Staying vigilant with calibration and cleaning keeps your sprayer ready for any project. Additionally, understanding the performance upgrades available for similar equipment can help optimize your maintenance routine.

Long-Term Storage and Care

To guarantee your airless sprayer stays in top shape during long-term storage, you need to follow proper cleaning procedures and choose a suitable storage environment. Using protective coverings can prevent dust and moisture from damaging the equipment, and storing it in a cool, dry place helps preserve its parts. Taking these steps now will make it easier to get your sprayer ready for use when you need it again.

Proper Cleaning Procedures

Proper cleaning is essential for ensuring your airless sprayer stays in top condition during long-term storage. Before storing, thoroughly clean the paint mixing components to prevent leftover paint from hardening or clogging. Flush the system with solvent or water, depending on the paint type, to remove any residue. Pay special attention to the nozzle; clean and inspect it to maintain proper nozzle calibration for future use. Remove any filters or tips and clean them separately. Wipe down all exterior surfaces and store the spray gun in a dry, dust-free environment. Proper cleaning prevents corrosion, clogs, and damage, ensuring your sprayer remains ready for your next project and extends its lifespan.

Storage Environment Tips

After thoroughly cleaning your airless sprayer, choosing the right storage environment helps guarantee it stays in peak condition. Store it in a cool, dry place with proper humidity control to prevent rust and corrosion. Avoid areas prone to moisture or extreme temperature fluctuations. Maintaining stable temperature regulation is essential; high heat can degrade seals and hoses, while freezing temperatures may cause damage. Keep the sprayer away from direct sunlight and sources of heat, which can accelerate wear. Consider using a climate-controlled storage space or a well-ventilated garage. Proper storage not only preserves the equipment’s longevity but also ensures it’s ready for use when needed. Taking these steps minimizes the risk of damage and keeps your sprayer functioning smoothly over time. Additionally, ensuring good air quality in the storage area can help prevent mold and bacteria growth that might affect internal components air quality.

Protective Coverings Usage

Using protective coverings is essential for maintaining your airless sprayer during long-term storage. They shield your equipment from dust, moisture, and debris, helping preserve its durability. Proper coverings prevent corrosion and damage, extending the lifespan of your sprayer. When selecting protective coverings, ensure they are breathable to avoid trapping moisture inside. Store your equipment in a dry, cool place, and use appropriate coverings to keep it in top condition. Additionally, inspecting the ventilation system periodically helps prevent moisture buildup and potential damage.

Frequently Asked Questions

How Often Should I Replace Spray Tips or Nozzles?

Your spray tips and nozzles require regular spray tip replacement and nozzle wear inspection to maintain ideal performance. Generally, replace spray tips every 4-6 gallons of fluid used or sooner if you notice uneven spray patterns or clogging. Conduct nozzle wear inspection routinely, especially after heavy use or when spray quality declines. Prompt replacement ensures consistent application and prevents costly repairs, keeping your equipment in top shape and your project on schedule.

What Safety Precautions Are Necessary During Maintenance?

Think of safety as your shield in maintenance. Always wear personal protective gear like gloves, goggles, and masks to guard against hazards. Before starting, check for hazard signage indicating risks. Turn off and depressurize the sprayer, ensuring no residual pressure. Keep your workspace clear and well-lit. Following these precautions keeps you safe, prevents accidents, and helps maintain your equipment’s longevity. Safety isn’t optional; it’s your first line of defense.

Can I Use Alternative Cleaning Solutions for My Sprayer?

You can use alternative cleaning solutions, but you need to check their chemical compatibility first. Make certain the cleaning agents won’t damage your sprayer’s components or degrade seals. Always follow the manufacturer’s guidelines, and test a small area if unsure. Using incompatible cleaners could cause costly damage or affect performance. So, choose your cleaning agents wisely, prioritizing safe, compatible options to keep your sprayer in top shape.

How Do I Identify Early Signs of Equipment Wear?

You can spot early signs of equipment wear by keeping an eye out for performance decline — it’s often a red flag. Regular visual inspections help catch issues like leaks, corrosion, or worn-out seals before they worsen. Don’t wait for problems to blow up; instead, stay proactive. If you notice inconsistent spray patterns or increased pressure, it’s time to take action. Recognizing these signs early keeps your sprayer in tip-top shape.

What’S the Recommended Lifespan for Different Sprayer Components?

Understanding the recommended lifespan for sprayer components helps you plan maintenance and replacements effectively. Typically, you can expect seals and hoses to last about 1-2 years, while pumps and motors may have a lifespan of 3-5 years depending on usage and maintenance. By monitoring component durability and estimating lifespan, you guarantee ideal performance and avoid unexpected breakdowns, keeping your equipment in top shape. Regular inspections extend longevity and maintain efficiency.

Conclusion

Maintaining your airless sprayer might seem like a routine task, but neglecting it can turn simple upkeep into costly repairs. Think of daily inspections as your first line of defense and seasonal deep cleans as your safeguard against unexpected breakdowns. When you stay proactive, you guarantee smooth operation and longer equipment life. Remember, a well-maintained sprayer isn’t just about avoiding trouble — it’s about confidently tackling each project with dependable performance.