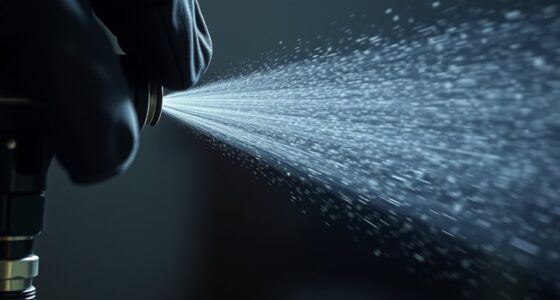

If you’re losing pressure mid-job, the culprit often hides in overlooked issues like faulty gauges or damaged hoses that silently cause pressure drops. Inaccurate readings or leaks from worn-out hoses can make you think the system’s fine, but the pressure is actually slipping away. Proper setup, regular inspections, and timely repairs prevent these problems. Keep exploring to discover more hidden causes that might be sabotaging your work without you realizing it.

Key Takeaways

- Regularly inspect and calibrate pressure gauges to ensure accurate readings and detect malfunctions early.

- Check hoses for cracks, leaks, or damage, replacing worn or compromised hoses before use.

- Ensure hoses are properly routed without kinks or bends to maintain consistent pressure flow.

- Tighten fittings securely and verify connections to prevent pressure leaks during operation.

- Conduct routine maintenance and system checks to identify hidden issues affecting pressure stability.

Losing pressure midway through a job can be frustrating and costly, but you don’t have to accept it as inevitable. Often, the root cause isn’t what you expect. You might blame your equipment or the power source, but the real culprit could be something more subtle: issues with pressure gauges or hose integrity. Recognizing and addressing these problems can save you time, money, and headaches in the long run.

First, consider your pressure gauges. These tools are essential for monitoring the system and ensuring everything runs smoothly. But they can also be sources of false readings if not maintained properly. Over time, pressure gauges can become clogged, damaged, or inaccurate due to dust, debris, or wear. If your gauge isn’t providing a true reading, you might be under-pressurizing or over-pressurizing your system without realizing it, leading to pressure drops during operation. Regularly calibrate and inspect your gauges to verify their accuracy. Replacing faulty gauges should be a priority, especially if you notice inconsistent readings or if the gauge needle sticks or fluctuates unexpectedly.

Regularly calibrate and inspect pressure gauges to ensure accurate readings and prevent pressure drops during operation.

Next, hose integrity plays a critical role in maintaining consistent pressure. Hoses are designed to handle specific pressures, but they can deteriorate over time. Cracks, leaks, or weak spots in the hose material can cause pressure to drop unexpectedly. Even small leaks might seem insignificant, but they can have a significant impact during prolonged jobs. Check your hoses regularly for signs of wear, such as brittleness, swelling, or visible damage. Ensure that fittings and connectors are secure, as loose connections can also cause pressure loss. Using high-quality hoses rated for your system’s pressure requirements helps prevent these issues. Remember, even a minor leak can sabotage your entire operation, so don’t overlook this aspect.

Another aspect to consider is the overall hose setup. Bends, kinks, or improper routing can restrict flow and cause drops in pressure. Keep hoses as straight and short as possible, avoiding sharp bends that can create resistance. Properly securing hoses prevents unnecessary movement or stress that could lead to damage. When you routinely check hose integrity and keep your pressure gauges calibrated, you’re proactively preventing pressure loss. This not only ensures your system operates efficiently but also extends the lifespan of your equipment. Additionally, understanding the thermal behavior of your system can help identify how temperature fluctuations might influence pressure stability and performance.

Ultimately, the key to stopping pressure drops mid-job isn’t just about the equipment itself but how well you maintain it. Regular inspection of pressure gauges and hoses, along with prompt repairs or replacements when needed, makes all the difference. Don’t wait until pressure drops to troubleshoot—stay vigilant. Your system will thank you with consistent performance, and you’ll avoid costly delays or damage caused by overlooked issues.

Frequently Asked Questions

Can Temperature Fluctuations Affect Pressure Retention?

Yes, temperature fluctuations can affect pressure retention. When temperatures rise, thermal expansion causes the air or fluid inside your system to expand, increasing pressure. Conversely, cooling leads to contraction, lowering pressure. Insulation effects help stabilize these temperature changes, minimizing pressure fluctuations. Without proper insulation, your system’s pressure can vary unpredictably, risking loss mid-job. Monitoring and managing temperature variations guarantees consistent pressure and prevents mid-job failures.

How Often Should Pressure Systems Be Inspected?

Think of your pressure system as a ticking clock—you need to check it regularly to keep it running smoothly. Inspection frequency depends on usage and environment, but generally, you should inspect your pressure systems at least quarterly. Incorporate maintenance scheduling into your routine to catch issues early, prevent pressure loss, and guarantee safety. Regular inspections protect your investment and keep operations seamless, like a well-oiled machine.

Are There Specific Tools to Detect Hidden Leaks?

Yes, you can use electronic sniffers and ultrasonic detectors to find hidden leaks. Electronic sniffers detect gas leaks by sensing the smell, while ultrasonic detectors pick up high-frequency sounds emitted by leaks. These tools are highly effective, allowing you to pinpoint leaks quickly without dismantling equipment. Regularly using these devices guarantees you catch leaks early, preventing pressure loss and maintaining system efficiency during your jobs.

What Are Common Signs of Pressure Loss?

Imagine your pressure gauge accuracy slipping just like a leaky faucet—small signs that tell you something’s wrong. Common signs of pressure loss include lower-than-expected readings, inconsistent pressure, or equipment struggling to perform. Regularly check leak detection methods and verify your gauges for accuracy. If you notice these signs, acting promptly can prevent bigger failures and keep your job on track. Don’t ignore the subtle hints; they’re your warning system.

Does Altitude Impact Pressure Stability?

Altitude effects can substantially impact pressure stability during your work. As you ascend, pressure variations occur because the air becomes thinner, causing tools and systems to lose pressure more quickly. You should monitor altitude effects closely, especially at higher elevations, to prevent unexpected pressure drops. Regularly check your equipment’s pressure levels, and consider using altitude compensation devices to maintain consistent pressure and avoid mid-job failures.

Conclusion

So, next time you notice your pressure dropping unexpectedly, remember it might just be the small, overlooked detail. Like a leaky valve or tiny crack in the line, these quiet culprits often go unnoticed until it’s too late. Keep an eye on every connection and check regularly; otherwise, you might find yourself chasing a ghost, just like trying to hold onto a mist that slips through your fingers. Stay vigilant, and pressure won’t surprise you.