To prevent paint leaks at hose connections, choose high-quality hoses with durable materials and inspect fittings for damage before use. Tighten connections firmly by hand, and use a wrench for an extra quarter turn if needed, but avoid over-tightening. Wrapping thread sealant tape around threaded ends helps create a secure seal and prevents leaks. Regularly check fittings and hoses for wear or looseness, and replace any damaged parts to keep your setup leak-free—if you want more tips, keep going.

Key Takeaways

- Use high-quality hoses made from durable materials to ensure secure connections and reduce leak risks.

- Inspect fittings for damage or deformities before connecting, replacing worn parts as needed.

- Tighten connections firmly by hand, adding a quarter turn with a wrench if necessary, without over-tightening.

- Wrap 1-3 layers of Teflon or thread sealant tape around threaded ends to improve sealing.

- Regularly check and maintain fittings and hoses, tightening or replacing components to prevent leaks during use.

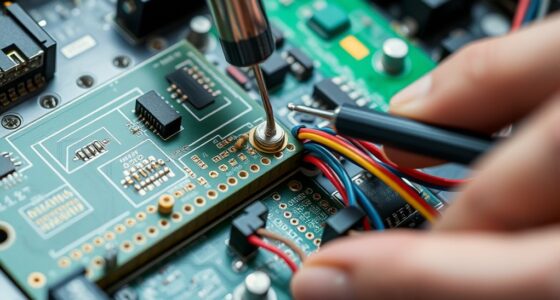

Paint leaks at hose connections can be frustrating and wasteful, but they’re often easy to prevent with proper techniques. The first step is to pay attention to the hose material, as it plays a fundamental role in how well your connection holds. Not all hoses are created equal—some are made from flexible rubber, others from durable vinyl, and some have reinforced layers for extra strength. Choosing a high-quality hose suited for your painting needs ensures a more secure connection. A hose with a sturdy, well-designed fitting reduces the risk of leaks, especially when paired with the right accessories. When connecting your hose, always inspect the fittings for any damage or deformities that could compromise the seal. Damaged or worn fittings are common culprits behind leaks, and replacing them can save you headaches later.

Next, focus on connection tightening. This step might seem simple, but it’s imperative. When attaching your hose to the spray gun, paint can flow out if the connection isn’t tight enough. Conversely, over-tightening can damage threads or strip fittings, leading to leaks and the need for replacements. To get it just right, hand-tighten the connection firmly, then give it a quarter turn with a wrench if necessary, but avoid excessive force. Use your fingers or a wrench to ensure the connection feels snug without forcing it. Also, check for any rubber or thread sealant tape—like Teflon tape—that might be missing or improperly applied. Wrapping a few layers of this tape around the threaded end before screwing on the fitting creates a better seal and prevents leaks. Make sure the tape is applied smoothly and wraps in the same direction as you tighten the connection, so it doesn’t unravel.

Maintaining proper connection tightness isn’t a one-time fix; it’s an ongoing process. Regularly inspect your hose fittings for any signs of loosening or wear, especially after prolonged use or storage. Tighten connections gently if you notice any leaks, but never force them beyond their comfortable snugness. If leaks persist despite tightening, consider replacing worn fittings or the hose itself. It’s also a good idea to periodically check the hose material for cracks or signs of deterioration, as these can also cause leaks at the connection point. Proper hose material selection combined with attentive connection tightening forms the foundation of a leak-free setup, helping you complete your painting projects efficiently and cleanly. Additionally, understanding the importance of hose fitting quality can ensure long-lasting, leak-free connections.

Frequently Asked Questions

Can Using Teflon Tape Prevent All Types of Leaks?

Using Teflon tape can considerably improve sealant effectiveness, but it doesn’t prevent all types of leaks. You might still encounter leaks if the tape isn’t applied correctly or if the connection is damaged. For best results, make sure you wrap Teflon tape tightly and evenly around threads. While it’s a reliable solution, combining it with proper tightening and inspection helps prevent most leaks, but it’s not foolproof for every situation.

What Is the Ideal Torque for Tightening Hose Connections?

You should tighten hose connections to about 25-30 inch-pounds of torque, enough to secure the connection without risking damage. For hoses made of flexible rubber or reinforced materials, avoid overtightening—think of it as tightening just enough to make the connection firm, not crush it. Pay attention to the connection design; some fittings require less torque, while others need a bit more to prevent leaks.

Are There Specific Hoses Better Suited for Paint Applications?

Yes, you should choose hoses made from materials like polyurethane or PVC, which are resistant to paint chemicals and easy to clean. Confirm the hose material is compatible with your paint type and equipment to prevent leaks. Opt for hoses with secure, compatible connections to avoid fitting issues. Selecting the right hose material and connection compatibility helps you achieve a smooth, leak-free paint application.

How Often Should Hose Connections Be Inspected for Leaks?

You should inspect hose connections for leaks at least once a day if you’re using them regularly, or before each project if less frequent. Regular inspection frequency helps you catch issues early, ensuring leak prevention and maintaining ideal spray performance. Look for cracks, loosened fittings, or drips, and tighten or replace parts as needed. Consistent checks keep your equipment in top shape and prevent messy, costly leaks during painting.

Do Different Paint Types Require Different Connection Techniques?

Imagine selecting the right brush for a delicate watercolor or bold oil—your hose connection needs similar care. Different paint types, like latex or oil-based, demand specific nozzle selection and proper connection techniques to prevent leaks. Consider paint compatibility; using incompatible tools can cause drips or sprays. Adjust your connection method accordingly, ensuring the nozzle matches the paint’s viscosity and properties, so your application stays smooth and leak-free.

Conclusion

So, next time you’re meticulously sealing your hose connections, remember that a tiny leak can turn your perfect paint job into a colorful mess. Ironically, the very effort to prevent leaks often causes them—tightening too much or skipping the proper fittings. Keep it simple, double-check your connections, and you’ll avoid those frustrating drips. After all, the only thing that should be leaking today is your creativity, not your paint.