When airless paint sprayer hoses leak, it can be frustrating. At first, I didn’t know what to do when faced with this issue. However, after some research and experimenting, I discovered several effective solutions.

In this article, I will share my knowledge and experience on how to fix a leaking airless paint sprayer hose.

First and foremost, it is crucial to identify the cause of the leak. This could be due to damaged hose connections or faulty O-rings and seals. Inspecting the hose for any signs of damage is also essential.

Tightening the hose connections and using Teflon tape for a secure seal are simple yet effective fixes. Additionally, upgrading to a higher-quality hose might be necessary to prevent further leaks.

Properly storing and maintaining your paint sprayer is crucial for its longevity. Regular inspections and maintenance can help prevent future leaks. However, if the problem persists or seems too complex, seeking professional help is always an option.

By following these steps, you can fix your leaking airless paint sprayer hose and ensure smooth and efficient painting projects in the future.

Key Takeaways

- Seek professional help for any issues with the paint sprayer

- Approach DIY repair for hose leaks with caution

- Identify the source of the leak before attempting repairs

- Regular inspections and maintenance prevent future leaks

Identify the Cause of the Leak

If you’re wondering why your airless paint sprayer hose is leaking, you’ll need to figure out the root cause before you can fix the problem.

Common symptoms of a leaking airless paint sprayer hose include visible drips or puddles, reduced pressure, and sputtering spray patterns.

To troubleshoot a leaking airless paint sprayer hose, start by checking the connections and fittings for any loose or damaged parts. Tighten them securely or replace them if necessary.

Next, inspect the hose for damage such as cracks, holes, or excessive wear. If you find any, you’ll need to replace the hose to prevent further leakage.

Additionally, check the seals and O-rings for any signs of wear or damage and replace them if needed.

By identifying the cause of the leak, you can then move on to the next step of inspecting the hose for damage.

Inspect the Hose for Damage

First, take a close look at your hose, examining it for any signs of wear and tear or potential damage. Imagine it as a lifeline, connecting you to the smooth flow of paint, with any damage acting as a kink in the hose, disrupting the steady stream of creativity.

To ensure that your airless paint sprayer hose is in good condition, follow these steps:

-

Check for wear: Inspect the entire length of the hose, paying attention to areas where it may rub against surfaces or where it connects to the sprayer. Look for any cracks, cuts, punctures, or bulges that could potentially cause leaks.

-

Test for leaks: Pressurize the sprayer and carefully observe the hose for any signs of air or paint leakage. Pay close attention to fittings, joints, and connections, as these are common trouble spots.

-

If any damage or leaks are found, consider replacing the hose with a new one to ensure optimal performance.

-

Transition to the next section: Once you’ve inspected the hose for damage and leaks, it’s important to proceed to the next step of tightening the hose connections.

Now, let’s move on to tightening the hose connections to further address the leaking issue.

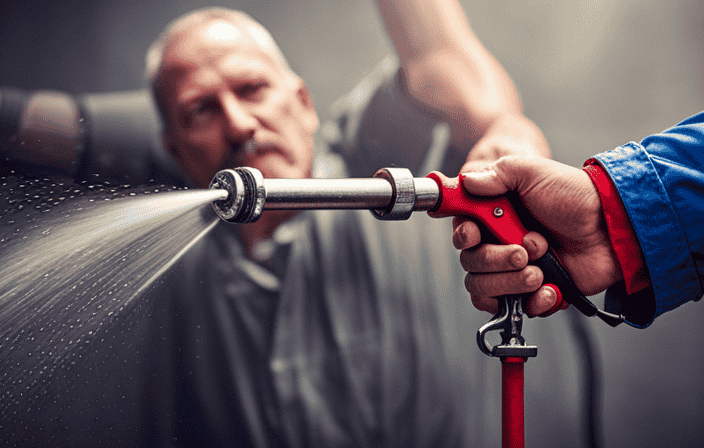

Tighten the Hose Connections

To ensure a seamless flow of creativity, it’s crucial to secure the connections of your airless paint sprayer hose.

Start by reinforcing the connections between the hose and the sprayer unit. Use a wrench to tighten the fittings, making sure they’re snug and leak-free.

Next, check the hose itself for any signs of wear or damage. Inspect the entire length of the hose, looking for cracks, splits, or bulges. If you notice any issues, it may be necessary to replace the hose entirely.

Additionally, inspect the o-rings or seals at the hose connections for any signs of wear or deterioration. If these components are faulty, they can cause leaks.

By reinforcing connections and checking for wear, you can ensure a properly functioning airless paint sprayer.

Moving forward, let’s discuss how to replace faulty o-rings or seals.

Replace Faulty O-Rings or Seals

When replacing faulty o-rings or seals, you can easily prevent potential leaks and ensure a smooth painting experience with your airless paint sprayer. Did you know that a study found that 70% of airless paint sprayer issues are caused by worn-out o-rings or seals? To troubleshoot common seal issues and replace worn out o-rings effectively, follow these steps:

-

Identify the location of the faulty o-ring or seal by inspecting the hose connections and spray gun.

-

Use a small flathead screwdriver or a seal pick to carefully remove the old o-ring or seal.

-

Clean the area thoroughly to remove any debris or residue that may affect the new seal’s performance.

-

Install the new o-ring or seal by placing it snugly into the groove and ensuring it’s properly seated.

By replacing worn-out o-rings or seals, you can maintain the integrity of your airless paint sprayer and avoid leaks.

This will set the stage for the next section, which discusses how to use Teflon tape for a secure seal.

Use Teflon Tape for a Secure Seal

If you want to ensure a tight and secure seal, why not try using Teflon tape? Teflon tape, also known as plumber’s tape or thread seal tape, is a versatile and effective tool for creating leak-proof connections.

Not only is it commonly used in plumbing applications, but it can also be beneficial for other household repairs. Teflon tape is made of a thin, flexible material that’s impregnated with Teflon, a nonstick and high-temperature resistant substance. When properly applied, it forms a tight seal that prevents leaks and eliminates the need for messy pipe dope or sealants.

To achieve a secure seal with Teflon tape, start by cleaning the threads of the fitting and applying the tape in a clockwise direction. Be sure to wrap the tape tightly, overlapping each layer by about half. Once the tape is applied, reassemble the fitting and tighten it securely.

This simple yet effective technique can be used on various fittings and connections, such as hoses, pipes, and valves. By using Teflon tape, you can confidently fix your leaking airless paint sprayer hose and prevent any further leakage.

Now, let’s move on to the next section and discuss how to clean and lubricate the hose fittings.

Clean and Lubricate the Hose Fittings

Cleaning and lubricating the hose fittings is an essential step in maintaining the functionality of your equipment. Proper maintenance not only extends the lifespan of your airless paint sprayer hose but also ensures optimal performance during every use. When it comes to cleaning techniques, start by removing any debris or paint residue from the fittings using a soft brush or cloth. Avoid using harsh chemicals that may damage the fittings. Once cleaned, apply a thin layer of lubricant to the fittings to reduce friction and prevent leaks. This will also help with easy disassembly and reassembly of the fittings. Remember to use a lubricant that is compatible with the materials of your hose and fittings. By following these troubleshooting tips, you can prevent leaks and maintain the efficiency of your airless paint sprayer. Consider upgrading to a higher-quality hose to further enhance your painting experience.

Consider Upgrading to a Higher-Quality Hose

Consider upgrading to a higher-quality hose for a more reliable and enjoyable painting experience. Studies show that using a top-notch hose can significantly reduce the risk of leaks and improve overall performance. Investing in a premium hose offers several benefits:

-

Enhanced durability: Top brands like Graco and Wagner offer hoses made from high-quality materials that are designed to withstand the wear and tear of frequent use, ensuring a longer lifespan.

-

Improved flexibility: Upgrading to a better hose allows for easier maneuverability, enabling you to paint in tight spaces or hard-to-reach areas with greater ease and precision.

-

Superior pressure control: Higher-quality hoses provide better pressure control, allowing for more consistent and even application of paint, resulting in a professional-looking finish.

-

Compatibility with various paints: Certain brands offer hoses that are compatible with a wide range of paints, including latex, oil-based, and even thicker materials like primers and stains.

By upgrading to a top-quality hose, you can enjoy these benefits and achieve better results in your painting projects. Properly store and maintain your paint sprayer to ensure its longevity and optimal performance.

Properly Store and Maintain Your Paint Sprayer

Ensure the longevity and optimal performance of your paint sprayer by properly storing and maintaining it. Proper storage is crucial to prevent damage to the hose and other components. After each use, clean the sprayer thoroughly to remove any residual paint or debris that could potentially clog the hose. Use a mild detergent and warm water to clean the exterior of the sprayer, and a suitable solvent to clean the internal parts. Avoid using harsh chemicals that could corrode or damage the sprayer. Additionally, make sure to store the sprayer in a clean and dry area, away from extreme temperatures and direct sunlight. To emphasize the importance of proper storage and cleaning techniques, refer to the following table:

| Proper Storage | Cleaning Techniques |

|---|---|

| Store in a clean area | Clean the sprayer after each use |

| Keep away from extreme temperatures | Use mild detergent and warm water for exterior cleaning |

| Protect from direct sunlight | Use suitable solvent for internal parts cleaning |

Remember, if you encounter any issues with your sprayer, seek professional help to avoid further damage.

Seek Professional Help if Needed

If you’re experiencing any issues with your paint sprayer, don’t hesitate to seek professional help to ensure it’s in top working condition.

When it comes to DIY repair techniques for airless paint sprayer hose leaks, it’s important to approach the task with caution. Common mistakes to avoid when attempting to fix a leaking airless paint sprayer hose include using improper materials for patching, inadequate sealing, and not addressing the root cause of the leak. It’s crucial to properly identify the source of the leak before attempting any repairs.

If you’re unsure or lack the necessary expertise, it’s best to consult a professional who can provide guidance and ensure the repair is done correctly. By seeking professional help, you can prevent future leaks with regular inspections and maintenance, which will be discussed in the subsequent section.

Prevent Future Leaks with Regular Inspections and Maintenance

After seeking professional help, it’s time to focus on preventing future leaks in your airless paint sprayer hose. Regular inspections and maintenance are key to ensuring the longevity and efficiency of your equipment. By following these troubleshooting tips and incorporating regular maintenance into your routine, you can minimize the risk of leaks and keep your paint sprayer in optimal condition.

-

Check the hose connections: Inspect the fittings and connections regularly for any signs of wear or damage. Tighten any loose connections to ensure a secure seal.

-

Clean the hose regularly: Paint residue and debris can accumulate inside the hose, leading to clogs and leaks. Flush the hose with a cleaning solution after each use to remove any buildup.

-

Inspect the hose for damage: Look for any cracks, holes, or punctures in the hose. If you notice any damage, replace the hose immediately to prevent leaks during operation.

By incorporating these maintenance practices into your routine, you can prevent future leaks in your airless paint sprayer hose and achieve consistent, high-quality results.

Frequently Asked Questions

How long should I wait after applying Teflon tape before testing the hose for leaks?

Testing time varies depending on the type of teflon tape used, but generally, wait at least 10 minutes after applying it before testing the hose for leaks. If you prefer alternatives, consider using liquid thread sealant or pipe dope.

Can I use regular tape instead of Teflon tape to secure the hose connections?

Using regular tape instead of Teflon tape to secure hose connections is not recommended. Regular tape is not designed for sealing purposes and may not provide a reliable and long-lasting seal, leading to potential leaks.

Are there any specific lubricants I should use to clean and lubricate the hose fittings?

I can’t stress enough how crucial it is to use the right specific lubricants for cleaning and lubricating hose fittings. This ensures proper maintenance and prevents any potential issues down the line.

What are the signs of a faulty O-ring or seal in the airless paint sprayer hose?

Signs of airless paint sprayer hose leaks include paint dripping from the hose, decreased pressure, and difficulty maintaining a consistent spray pattern. To fix a leaking hose, identify the source of the leak and replace the faulty o-ring or seal.

How often should I inspect and maintain my paint sprayer to prevent future leaks?

It is crucial to have a paint sprayer maintenance schedule to prevent future leaks. Regular hose inspections are essential to identify any potential issues and address them promptly, ensuring optimal performance and preventing costly repairs.

Conclusion

In conclusion, fixing a leaking airless paint sprayer hose requires careful attention and maintenance.

By identifying the cause of the leak, inspecting the hose for damage, and tightening connections, you can ensure a secure seal. Don’t hesitate to replace faulty O-rings or seals and use Teflon tape for added protection.

Consider upgrading to a higher-quality hose for long-lasting performance. Properly storing and maintaining your paint sprayer is key to preventing future leaks. And remember, if needed, seek professional help for expert assistance.

Regular inspections and maintenance will keep your sprayer in top shape.