Pump saver fluids are additives designed to reduce wear, prevent corrosion, and improve your pump’s efficiency by forming a protective barrier inside the system. Use them during routine maintenance, when you notice signs of wear, or at startup to help extend your pump’s lifespan. Regular application can prevent costly repairs and keep your system running smoothly. Want to discover the best times and methods to use pump saver fluids effectively? Keep exploring for more insights.

Key Takeaways

- Pump saver fluids create a protective barrier, reducing wear, corrosion, and debris buildup inside the pump.

- They help maintain peak efficiency and extend pump lifespan by preventing metal contact and mineral deposits.

- Use pump saver fluids during routine maintenance, startup, or when signs of wear like noise or vibration appear.

- Proper application and compatible fluids ensure optimal protection and prevent unexpected failures.

- Regular use in high-load or corrosive environments supports long-term operation and reduces maintenance costs.

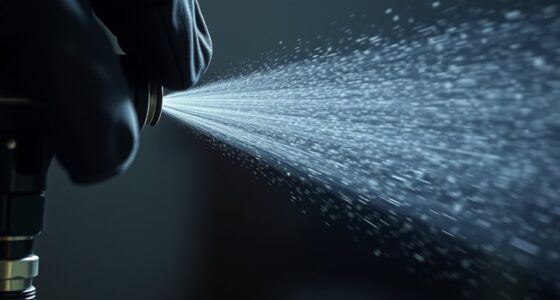

Are you looking for a simple way to extend the life of your pump and prevent costly breakdowns? Pump saver fluids are designed to do just that. They are specially formulated liquids that you add to your pump’s system to reduce wear, minimize corrosion, and improve overall efficiency. These fluids work by creating a protective barrier inside the pump, which helps prevent metal-to-metal contact and reduces the accumulation of debris or mineral deposits. Using pump saver fluids can considerably cut down on maintenance costs and downtime, making them a smart investment for anyone relying on pumps regularly.

Extend your pump’s lifespan with pump saver fluids that reduce wear and prevent corrosion.

When you choose to use a pump saver fluid, timing is key. Typically, you should add it during routine maintenance or when you notice signs of wear, such as unusual noises, vibrations, or decreased performance. If your pump handles water with high mineral content, corrosion, or chemicals, it’s especially important to use a suitable fluid to protect against these harsh conditions. For new pumps, it’s advisable to add the fluid at startup to establish a protective layer from the beginning. In systems with a history of corrosion or buildup, regular use of pump saver fluids can help maintain peak operation and prevent premature failure.

You don’t need to worry about complex procedures to apply these fluids. Most pump saver products are designed for easy use—just add them directly into the system according to the manufacturer’s instructions. Some formulations are compatible with specific types of pumps, so always check the label to ensure it matches your equipment. For pumps that operate continuously or under heavy loads, more frequent application might be necessary. In contrast, pumps running intermittently may require less frequent use, but regular application still offers benefits.

Using pump saver fluids is particularly valuable in industrial, municipal, or agricultural settings where pumps operate under demanding conditions. They can also be beneficial in systems with variable water quality, such as wells or recycled water systems, where mineral and chemical content fluctuate. Additionally, incorporating preventive maintenance practices like using pump saver fluids can significantly extend the lifespan of your equipment. Remember, the goal isn’t just to add a fluid but to choose the right one for your specific needs. Proper selection and regular application help extend your pump’s lifespan, improve efficiency, and prevent unexpected failures. In the end, a simple step like adding pump saver fluids can save you money, reduce downtime, and keep your equipment running smoothly for years to come.

Frequently Asked Questions

Can Pump Saver Fluids Be Used in All Types of Pumps?

Yes, you can generally use pump saver fluids in most types of pumps, but you should verify the manufacturer’s recommendations first. Different pumps have unique requirements, so using the wrong fluid could cause damage or reduce efficiency. Always verify compatibility with your specific pump model and application. When in doubt, consult the pump’s manual or a professional to ensure you’re choosing the right fluid for your equipment.

Are There Any Environmental Impacts of Using Pump Saver Fluids?

Imagine your pump fluids turning into tiny eco-villains, sneaking into waterways and upsetting aquatic life. While pump saver fluids are designed to be environmentally friendly, some may contain chemicals that pose risks if mishandled or spilled. You should always check labels and follow disposal instructions. Think of it as giving your pump a green thumb, but only if you’re cautious about the tiny villains you might be releasing.

How Often Should Pump Saver Fluids Be Replaced?

You should replace pump saver fluids every 6 to 12 months, depending on usage and manufacturer recommendations. Regularly check the fluid levels and condition, especially if your pump operates in harsh conditions or shows signs of wear. Consistent replacement guarantees peak performance and longevity of your equipment. Keep an eye on any manufacturer updates for specific intervals, and don’t forget to follow safety guidelines when handling and disposing of fluids.

Do Pump Saver Fluids Require Special Storage Conditions?

You might think pump saver fluids need fancy storage, but they actually don’t require special conditions. Keep them in a cool, dry place away from direct sunlight and extreme temperatures, just like any other fluid. Avoid freezing or excessive heat to maintain their effectiveness. Simple storage keeps your pump saver fluids ready to go when you need them, proving that sometimes, less fuss is more.

Can Pump Saver Fluids Be Mixed With Other Pump Maintenance Products?

You shouldn’t mix pump saver fluids with other pump maintenance products. Mixing can cause chemical reactions that might reduce effectiveness or damage your pump. Always follow the manufacturer’s instructions and use each product separately to guarantee peak performance. If you’re unsure about compatibility, consult the product label or contact the manufacturer. Keeping products separate helps you maintain your pump’s efficiency and prevents potential issues caused by mixing chemicals.

Conclusion

Using pump saver fluids can gently extend the life of your equipment, helping you avoid the hassle of unexpected repairs. When you choose to care for your pump proactively, you’re ensuring smoother operation and fewer worries down the road. Think of it as giving your system a caring touch, allowing it to perform quietly and reliably. A small step now can bring peace of mind tomorrow, letting your work flow effortlessly and without interruption.