Spray gun filters are designed to capture dust, overspray, and debris near the nozzle, ensuring a smooth finish and protecting delicate parts, but they need frequent cleaning and are best for detailed, smaller-scale projects. Pump filters, installed downstream, trap finer debris and fluids, protecting your equipment during larger, continuous jobs. They last longer and handle higher volumes but come at a higher initial cost. If you want to understand which filter suits your needs, keep exploring the differences.

Key Takeaways

- Spray gun filters are positioned near the nozzle for fine debris removal; pump filters are installed downstream to protect the pump and equipment.

- Spray gun filters target airborne particles like dust and overspray, while pump filters remove debris, oils, and solvent residues from fluid flow.

- Spray gun filters are smaller, easier to clean frequently, but require regular replacements; pump filters are larger, durable, and need less frequent maintenance.

- Spray gun filters generally have lower initial costs but higher replacement frequency; pump filters have higher upfront costs but longer service life.

- Spray gun filters improve finish quality in detailed environments; pump filters ensure consistent flow and protect equipment during large-scale applications.

Purpose and Functionality of Spray Gun Filters

Spray gun filters play a essential role in maintaining the quality of your finish by trapping debris and contaminants before they reach the spray gun. The filter material is designed to capture particles that could mar your paint job, guaranteeing a smooth application. The flow rate is key because it determines how efficiently the filter allows paint and air to pass through without clogging or restricting movement. A good filter material balances filtration efficiency with minimal impact on flow rate, helping you achieve consistent spray patterns. Additionally, using high-quality filter materials can further enhance your results by providing better particle capture and durability. Properly selecting filters that match your project requirements can significantly improve overall performance. By filtering out impurities early, these filters protect your equipment and improve the final finish. Properly selected spray gun filters keep debris out, maintain ideal flow, and ensure your project stays clean and professional-looking. Additionally, choosing filters compatible with personal development tools can maximize your workflow efficiency and overall project success. Regular maintenance of your filters is also crucial to prevent buildup that can compromise filter efficiency and spray quality. Incorporating filter lifespan considerations can help you choose options that require less frequent replacement and reduce downtime.

Purpose and Functionality of Pump Filters

Pump filters are essential for maintaining efficient filtration, preventing debris from reaching your equipment. They serve as a protective barrier, reducing the risk of clogs and damage. Understanding their role helps you keep your system running smoothly and extend its lifespan. Regular maintenance of filtering options ensures optimal performance and longevity of your spray system. As AI technology continues to advance, implementing safety measures can help identify potential issues before they affect your equipment. Additionally, choosing the right filter type can optimize the filtration process and improve overall system efficiency. Incorporating proper maintenance routines also promotes consistent operation and reduces downtime.

Filtration Process Efficiency

Because efficient filtration is essential for maintaining consistent spray quality, pump filters play a critical role in the process. They guarantee airflow optimization by removing debris that could clog the system, which improves spray consistency. Additionally, pump filters are designed for high chemical resistance, preventing deterioration when filtering aggressive substances. This combination maintains steady pressure and minimizes downtime. To understand their impact better, consider this: Filtration accuracy ensures the removal of particles that could compromise the quality of the spray. Proper filter maintenance is also vital to sustain optimal performance over time, reducing the risk of unexpected system failures. Incorporating filter lifespan considerations can help plan timely replacements and avoid productivity losses. Moreover, integrating automation in filtration systems can enhance monitoring and scheduling maintenance, further increasing efficiency. The filter material used in pump filters influences their durability and compatibility with different chemicals, making it a crucial factor in system longevity. This focus on efficiency helps you achieve superior finishes while reducing maintenance and ensuring long-term reliability.

Protective Mechanism Role

Efficient filtration not only maintains spray quality but also safeguards your equipment from potential damage. Pump filters serve as a crucial protective barrier, preventing debris and contaminants from reaching sensitive components. The filter material is designed to trap particles that could clog or damage the pump, ensuring smooth operation. By doing so, it reduces maintenance downtime and extends the lifespan of your equipment. Regularly inspecting and replacing filters is vital for maintaining optimal performance and preventing clogging issues. Proper filtration also contributes to consistent spray quality, which is essential for professional results. Understanding filter maintenance practices is key to ensuring your system remains in peak condition. Proper filtration also helps prevent damage to internal components, ensuring the longevity of your equipment. Key roles include: – Blocking large particles that could cause damage – Maintaining consistent spray performance – Protecting delicate internal parts – Ensuring reliable operation over time With a robust protective barrier, your pump stays cleaner, runs efficiently, and minimizes costly repairs. Proper filtration is essential for safeguarding your investment and achieving high-quality results.

Location and Placement Within the Spraying System

The placement of filters within a spraying system considerably impacts their effectiveness and ease of maintenance. You should position spray gun filters close to the gun itself, typically right at the nozzle or inlet, to catch debris before it enters the spray tip. Pump filters, on the other hand, are best installed downstream of the pump, often just before the fluid reaches the spray gun, to protect the entire system. The filter material must be compatible with your fluid type and particle size, ensuring ideal filtration without restricting flow. Proper installation location helps prevent clogs and reduces maintenance frequency. Keeping filters accessible also simplifies cleaning and replacements, maintaining consistent spray quality and prolonging equipment life. Using pressure regulation can also enhance filter performance and system longevity. Additionally, selecting filters designed specifically for your Volkswagen Tuning application can optimize their performance and durability. Proper positioning of filters plays a crucial role in maintaining optimal system efficiency and reducing downtime for maintenance.

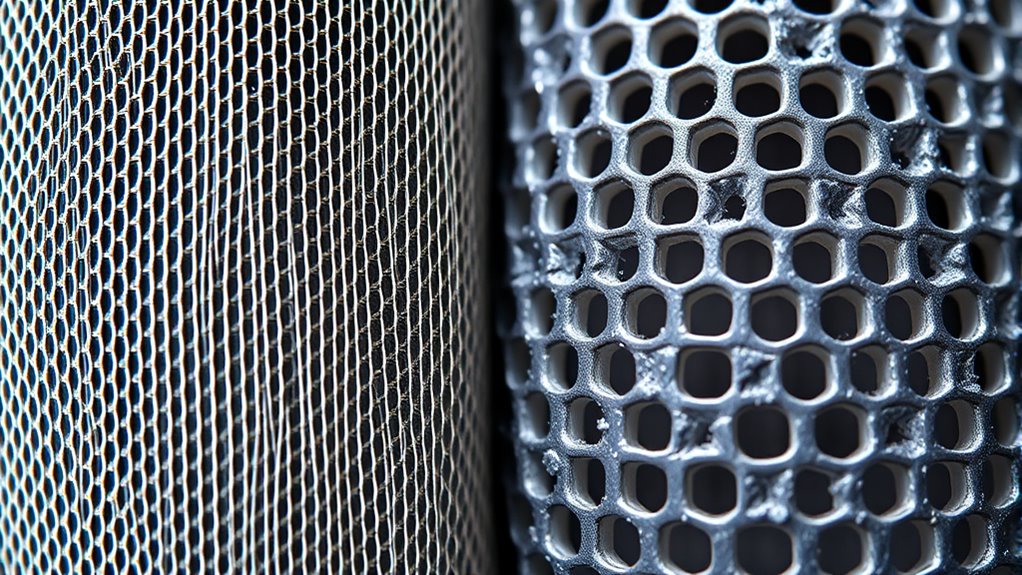

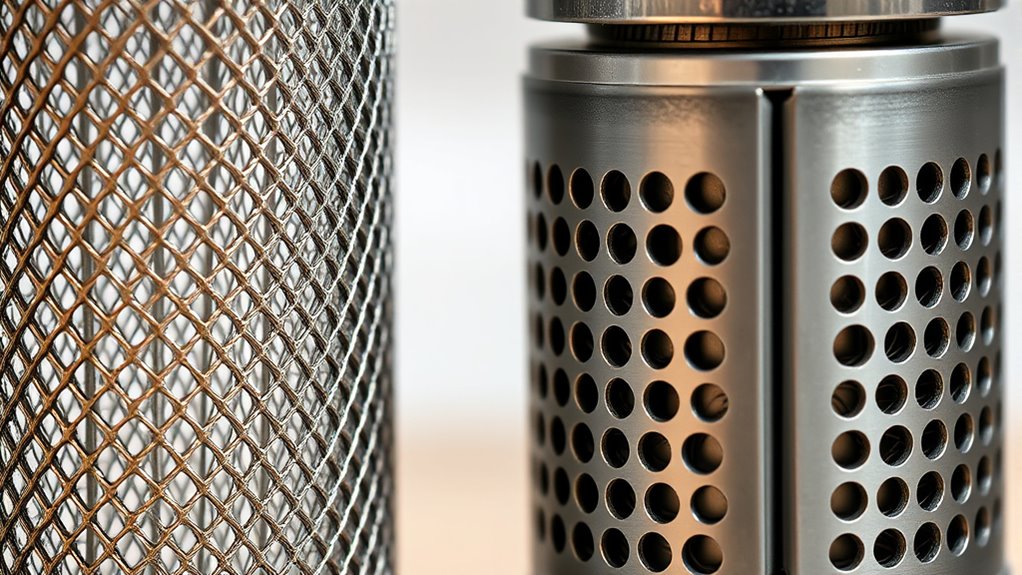

Design and Construction Differences

Spray gun filters and pump filters differ markedly in their design and construction, reflecting their specific roles within the spraying system. You’ll notice that pump filters often feature a larger filter material for handling higher volumes, with a sturdy mounting design to withstand pressure. Conversely, spray gun filters are typically smaller, focusing on precise filtration with finer filter material to catch tiny particles. Key differences include:

- Filter material: Pump filters use durable, high-capacity materials; spray gun filters favor fine, precise filters. This distinction ensures that each filter type performs optimally within its designated function.

- Mounting design: Pump filters have robust, secure mounts; spray gun filters feature compact, easy-to-access mounts, facilitating quick maintenance and adjustments.

- Size and shape: Pump filters are larger and bulkier; spray gun filters are streamlined for portability.

- Accessibility: Spray gun filters are designed for quick cleaning, while pump filters prioritize durability and volume handling. This design efficiency helps in reducing downtime and maintaining consistent spray quality.

- Additionally, the efficiency of filtration plays a crucial role in maintaining optimal spray system performance and preventing clogs.

Types of Contaminants Each Filter Targets

You need to understand which contaminants each filter captures to select the right one. Spray gun filters mainly target particulates and debris that can clog your equipment, while pump filters are designed to remove oil and solvent contaminants. Knowing these differences helps you prevent issues and ensure a smooth finish.

Particulates and Debris

While both spray gun filters and pump filters serve to keep contaminants out of your coating material, they target different types of particulates and debris. Spray gun filters mainly catch larger particles that can clog the air flow or affect paint viscosity, ensuring smooth application. Pump filters focus on finer debris that could damage the pump or cause inconsistent flow.

You should pay attention to:

- Dust and dirt particles that can enter during preparation

- Overspray or dried paint flakes

- Metal shavings or rust from equipment

- Fine debris from contaminated air or materials

These contaminants can alter paint viscosity and hinder proper atomization, so selecting the right filter helps maintain ideal spray performance and finish quality.

Oil and Solvent Contaminants

Oil and solvent contaminants can considerably impact your coating quality if not properly filtered out. These contaminants often originate from improper solvent compatibility or residual oils in your equipment. If your filter isn’t designed to handle specific solvents, they can pass through and cause defects like cloudiness or poor adhesion. Air pressure fluctuations can also influence how well these contaminants are removed; inconsistent pressure might force oils or solvents through insufficient filters. Pump filters are especially effective at capturing oil and solvent residues before they reach your spray gun, ensuring cleaner application. Choosing the right filter depends on your solvent type and maintaining proper air pressure. Proper filtration prevents contamination, improves finish quality, and extends equipment lifespan.

Maintenance Requirements and Longevity

Maintenance requirements and longevity can vary considerably between spray gun filters and pump filters. Spray gun filters typically need more frequent filter cleaning due to their exposure to airborne contaminants, which can shorten their filter lifespan if not maintained properly. Pump filters generally last longer, as they operate under pressure and are less exposed to external debris, but still require regular checks. To maximize efficiency, you should:

- Regularly clean filters to prevent clogging

- Replace filters when they show signs of wear or damage

- Keep track of filter lifespan to avoid performance issues

- Follow manufacturer guidelines for maintenance intervals

Proper maintenance ensures ideal spray quality and extends the lifespan of your filters, saving you time and money in the long run.

Impact on Spray Quality and Finish

Your spray quality depends on how well your filter maintains a clear spray pattern and consistent finish. If your filter clogs or isn’t effective, you might notice uneven coats or blemishes. Understanding how each filter type impacts these factors helps you achieve a smoother, professional finish.

Clarity of Spray Pattern

The clarity of the spray pattern directly influences the quality of your finish, as a well-defined pattern ensures even application and smooth coverage. When your spray pattern is clear, you achieve consistent spray distribution, reducing uneven spots or drips. Proper filter selection impacts spray consistency, making your pattern more uniform. Consider these points:

- Clear spray pattern enhances control over application

- Reduces overspray and waste

- Ensures smooth, even coats

- Maintains consistent spray quality throughout your project

A sharp, defined spray pattern contributes to a professional look, while blurry or inconsistent patterns can ruin your finish. By choosing the right filter, you improve spray clarity, helping you get the best results with less effort. Ultimately, clarity of the spray pattern is vital for achieving a flawless, high-quality finish.

Consistency of Finish

Choosing the right filter directly impacts the consistency of your finish by ensuring the spray remains steady and uniform throughout the project. A good filter prevents paint fumes from contaminating the spray, which can cause uneven application or blemishes. In a spray booth, maintaining a consistent finish is essential for professional results, and filters play a critical role in this. Pump filters, with their precise particle removal, help maintain a smooth, even coating without fluctuations. Spray gun filters also contribute to this consistency by trapping debris that could disrupt the spray pattern. When filters effectively block contaminants, you reduce the risk of streaks, sags, or blotches, ensuring your final finish looks flawless from start to finish.

Occasional Clogging Risks

Occasional clogging of filters can disrupt your spray process, leading to uneven paint flow and compromised finish quality. When filters clog, your air supply may become restricted, causing fluctuations in spray pressure. This inconsistency results in sputtering or uneven coats. To minimize risks:

- Regularly check and clean filters to maintain steady air supply

- Ensure your spray pressure is consistent and within recommended levels

- Use filters suited to your paint and application to reduce clogging chances

- Monitor for signs of reduced airflow or uneven spray, addressing issues promptly

Clogs can cause inconsistent atomization, affecting the smoothness of your finish. Staying proactive with filter maintenance helps guarantee optimal spray pressure and a flawless, professional look.

Compatibility With Different Equipment Types

Understanding how spray gun filters and pump filters work with different equipment types can substantially impact your painting process. The compatibility often depends on the equipment material and filter size. Spray gun filters are typically designed for smaller, more delicate nozzles and work best with lightweight equipment made of plastic or aluminum. Pump filters, on the other hand, are suited for larger, more robust systems made of metal or heavy-duty materials. Matching filter size to your equipment ensures ideal performance—using the right size prevents clogs and maintains flow consistency. Some filters are adaptable for multiple equipment types, but always check manufacturer specifications to avoid compatibility issues. Proper selection improves efficiency and reduces maintenance, making your painting tasks smoother and more reliable.

Cost Considerations and Replacement Intervals

Cost is a key factor when selecting between spray gun filters and pump filters, as their prices can vary considerably. A thorough cost comparison helps you determine which fits your budget over time. Generally, pump filters may have a higher initial cost but offer longer filter lifespan, reducing replacement frequency. Conversely, spray gun filters tend to be cheaper upfront but may need replacing more often, increasing long-term expenses. Consider these points:

Choosing between spray gun and pump filters depends on initial costs and long-term filter lifespan.

- Higher upfront costs for pump filters

- Longer filter lifespan with pump filters

- Frequent replacements for spray gun filters

- Total costs over the equipment’s lifespan

When to Use a Spray Gun Filter Versus a Pump Filter

Choosing between spray gun filters and pump filters depends on your specific spraying needs and the environment in which you’re working. If you’re painting in a spray booth, a spray gun filter is ideal because it helps prevent overspray and airborne debris from contaminating the paint. This ensures a cleaner finish and faster paint drying times. Use a spray gun filter when precision is critical, especially for detailed work or smaller projects. On the other hand, pump filters are better suited for larger, continuous applications where maintaining consistent paint flow is essential. They protect the pump from debris and reduce clogging risks. Consider your project’s scale and the environment to decide which filter type will deliver the best results while keeping your workspace efficient.

Frequently Asked Questions

Can Spray Gun Filters Be Used With All Types of Paints?

You might wonder if spray gun filters work with all types of paint. While they generally handle many paints, your choice depends on paint compatibility and filter limitations. Thinner paints flow easily, but thicker or textured paints may clog smaller filters. Always check the filter’s specifications and the paint’s viscosity to guarantee ideal performance and prevent damage or clogs during your spraying projects.

Are Pump Filters Necessary for Small-Scale Spray Operations?

Imagine a small-scale spray operation where precision, ease, and efficiency matter. You might wonder if pump filters are necessary — and they often are, for smooth paint flow and preventing clogs. Regular filter maintenance keeps them effective, ensuring filter compatibility with your paints. While some small setups can manage without, using pump filters can enhance your control, reduce downtime, and make your job easier, even on a smaller scale.

How Do Filters Affect Spraying Speed and Efficiency?

Filters play a key role in your spraying process by preventing filter clogging, which can slow you down. When filters are clean, you maintain consistent spray flow, boosting efficiency. Dirty filters cause interruptions, reducing your spray consistency and overall speed. Regularly checking and cleaning filters guarantees smooth operation, allowing you to complete jobs faster and with better results, making your spraying more efficient and professional.

Can Filters Be Cleaned and Reused Multiple Times?

You might worry about replacing filters often, but good cleaning procedures can preserve their filter longevity. Yes, filters can be cleaned and reused multiple times if you follow proper steps, like rinsing with suitable solvents and gently removing debris. Regular maintenance ensures they stay effective, saving you money and effort. With proper care, your filters remain functional, reducing waste and ensuring consistent spraying performance over time.

What Are the Environmental Impacts of Disposing of Used Filters?

When you dispose of used filters, consider the environmental impacts, as they often contain hazardous waste. You can explore recycling options to reduce waste, but improper disposal may harm ecosystems. Always check local regulations to guarantee proper handling. Recycling helps prevent pollution and minimizes landfill use, protecting the environment. By choosing responsible disposal methods, you contribute to sustainability and reduce the negative effects associated with hazardous waste.

Conclusion

Choosing the right filter depends on your equipment and project needs. Did you know that using the correct filter can improve spray quality by up to 30%? By understanding the differences between spray gun filters and pump filters, you can prevent costly defects and guarantee a flawless finish. Remember, regular maintenance and proper selection make all the difference in achieving professional results every time.