Swivel fittings enhance your spraying system by allowing hoses and pipes to rotate smoothly, which reduces strain, prevents kinks, and improves maneuverability. They come in various types and materials to suit different needs, offering flexibility for directional changes and complex spraying setups. Proper installation and maintenance ensure durability and leak-free performance. If you’re interested in maximizing the efficiency and lifespan of your spraying tasks, explore the details further to find the best swivel fitting for your application.

Key Takeaways

- Swivel fittings enable hose rotation, reducing strain and preventing kinks during spraying tasks.

- They improve flexibility, allowing hoses to maneuver easily around obstacles without damage.

- Made from materials like brass, stainless steel, or plastic to ensure durability and corrosion resistance.

- Different types of swivel fittings suit various applications, including threaded, quick-connect, and compression options.

- Proper installation and maintenance ensure leak-free operation and extend the lifespan of spraying systems.

Understanding the Functionality of Swivel Fittings

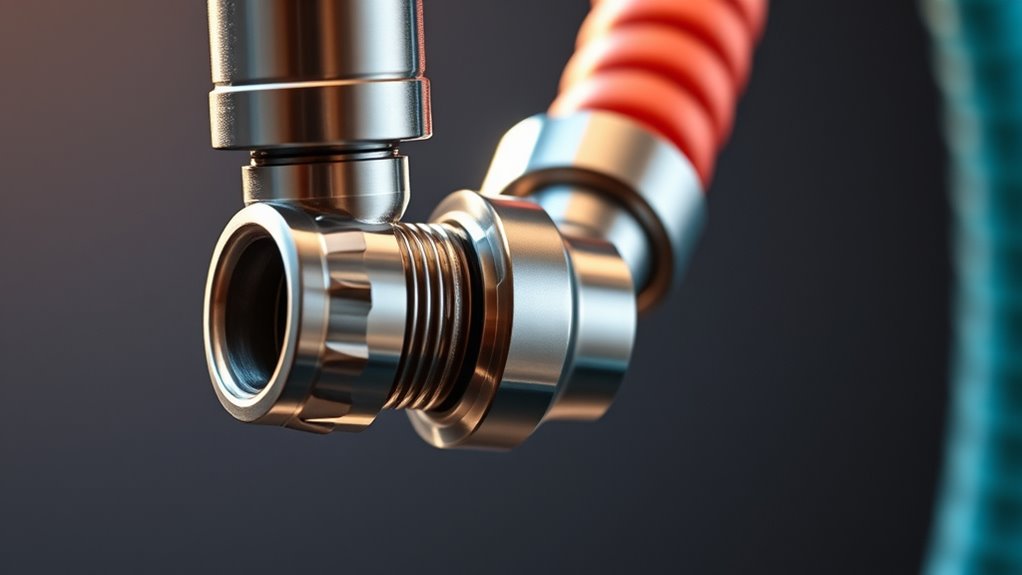

Have you ever wondered how swivel fittings allow for smoother movement and easier connections in piping systems? These fittings work by enabling rotation between connected pipes or hoses, reducing strain and preventing kinks. A key aspect is hose compatibility; swivel fittings are designed to fit various hose sizes and types, guaranteeing a secure connection. Sealing mechanisms are also essential—they prevent leaks during operation by using rubber or other materials that create a tight seal when the fitting is tightened. This combination of compatibility and sealing ensures that your system remains efficient and leak-free, even with frequent movement. Additionally, understanding the effectiveness of eye patches can help in choosing the right skincare products to maintain healthy skin around your fittings and connections. Proper safety features in fittings can further enhance durability and prevent accidents during installation or use. Moreover, considering manufacturer standards can ensure the longevity and reliability of your swivel fittings over time. Ensuring your fittings meet nutritional value of juices standards can help in selecting quality components that withstand operational stresses. Incorporating corrosion resistance into your selection process can also significantly extend the lifespan of your fittings in various environments.

Key Benefits of Using Swivel Fittings in Spraying Tasks

Ever wonder why swivel fittings are essential for spraying tasks? They enhance flexibility, allowing you to maneuver hoses easily without strain. This reduces wear and tear, extending equipment lifespan. Swivel fittings also simplify relabeling procedures since they make repositioning or replacing attachments quick and hassle-free. Their ability to prevent hose twisting means fewer interruptions and consistent spray patterns. From a cost analysis perspective, investing in swivel fittings can save you money by minimizing maintenance needs and reducing downtime. You’ll spend less time troubleshooting hose issues and more time on actual spraying. Additionally, using hose durability considerations ensures that your equipment remains resilient under demanding conditions. Incorporating ergonomic design principles can further improve handling and reduce operator fatigue. Moreover, energy efficiency benefits can be achieved by selecting fittings that minimize pressure loss and optimize flow. Overall, these fittings improve efficiency, durability, and ease of use, making them a smart choice for any spraying operation.

Types of Swivel Fittings and Their Applications

Different swivel fittings come with various ball joint designs, each suited for specific movement and load needs. You’ll also find a range of materials, so you can choose options that match your application’s pressure, temperature, and chemical compatibility. Understanding these variations helps you select the right fitting for reliable, efficient performance. Properly selecting and maintaining headphones compatibility can further enhance your experience by ensuring seamless integration with your devices and optimal sound quality. Being aware of odor detection can help prevent potential issues related to contaminants or malfunctions in your system. Additionally, considering performance ratings can guide you toward models that offer better durability and suction efficiency. Recognizing material durability is essential for selecting fittings that withstand harsh environmental conditions and extend their service life.

Ball Joint Variations

Ball joint variations are essential components in swivel fittings, offering a range of movement and flexibility to suit different applications. These variations differ in ball joint mechanics, which influence how smoothly and securely the fitting rotates. Some ball joints allow for multi-directional movement, ideal for complex spraying angles, while others provide limited rotation for simple tasks. The swivel fitting design incorporates these joints to maximize efficiency, reduce stress, and prevent leaks. You can choose from different types, such as spherical or tapered ball joints, depending on your needs. Understanding these variations helps you select the right swivel fitting for your setup, ensuring peak performance and durability. Additionally, selecting the appropriate ball joint variation can help accommodate specific application requirements, enhancing your spraying system’s flexibility and reliability. Recognizing the role of natural materials like wood and stone in these fittings can also contribute to a more durable and authentic setup. Incorporating proper maintenance practices can further extend the lifespan of your swivel fittings and maintain optimal performance. Moreover, knowing the regional availability of these fittings ensures easier access to the right components for your project. Furthermore, considering biodiversity principles when designing outdoor setups can promote a more sustainable and eco-friendly environment around your equipment.

Material Compatibility Options

Selecting the right swivel fitting depends heavily on the materials involved in your application, as not all fittings are compatible with every substance. Material options vary, including brass, stainless steel, plastic, and rubber, each offering different advantages. For applications involving harsh chemicals, choose fittings with high chemical resistance, such as stainless steel or specialized plastics like PTFE. If you’re working with corrosive fluids, avoid fittings made of softer metals or plastics that degrade easily. Consider the temperature range and pressure your system requires, as these factors influence material choice. Proper material compatibility ensures durability, prevents leaks, and maintains safety. Additionally, understanding material compatibility is essential for preventing system failures and ensuring safety during operation. Being aware of the corrosion resistance of different materials can significantly extend the lifespan of your fittings and system components. Furthermore, selecting fittings with suitable temperature ratings can help prevent deformation or failure under extreme conditions.

Materials and Durability of Swivel Fittings

Choosing the right materials for swivel fittings is essential because it directly impacts their durability and performance over time. Material strength ensures the fittings withstand high pressure and repeated movement without failure. Corrosion resistance is equally important, especially for outdoor or harsh environments, preventing rust and degradation. Common materials include brass, stainless steel, and plastic, each offering different benefits. Brass provides good strength and corrosion resistance at a lower cost. Stainless steel excels in durability and corrosion resistance, ideal for demanding conditions. Plastic fittings are lightweight and resistant to many chemicals but may lack the strength needed for high-pressure applications. Additionally, selecting materials with corrosion resistance can significantly extend the lifespan of fittings in diverse environments.

Installing and Maintaining Swivel Fittings for Optimal Performance

To guarantee your swivel fittings work smoothly, you need to focus on proper installation techniques. Regular maintenance, like checking for leaks and tightening connections, keeps them in top shape. By following these tips, you’ll maximize their lifespan and performance.

Proper Installation Techniques

Proper installation of swivel fittings is essential to guarantee they function smoothly and last longer. Begin by ensuring all connections are clean and free of debris. Use a hose clamp to secure hoses tightly around the fitting, preventing leaks and maintaining stability during operation. Before connecting, check the pressure gauge to confirm the system isn’t under excessive pressure, which could damage the fitting. When attaching the swivel fitting, tighten it firmly but avoid over-tightening, which could cause thread damage. Make sure the swivel moves freely after installation, indicating proper alignment. Regularly inspect the fittings for signs of wear or leaks, and adjust the hose clamp if needed. Following these steps helps optimize performance and durability while minimizing the risk of failure.

Routine Maintenance Tips

Regularly inspecting your swivel fittings is key to maintaining ideal performance. Check for leaks, wear, or corrosion, and address issues promptly. Proper lubrication techniques are essential—apply a suitable lubricant to moving parts to reduce friction and prevent rust. Additionally, using corrosion prevention methods, like applying a protective coating or storing fittings properly, extends their lifespan. To keep fittings functioning smoothly, consider these maintenance tips:

- Regularly clean fittings to remove dirt and debris

- Lubricate moving parts to ensure smooth rotation

- Apply corrosion inhibitors to prevent rust

- Tighten fittings to avoid leaks and maintain integrity

Comparing Swivel Fittings to Traditional Hose Connectors

Swivel fittings offer a significant advantage over traditional hose connectors by allowing for easier movement and reduced stress on hoses during use. They enhance hose flexibility, making it easier to maneuver around obstacles without kinking or twisting. Unlike standard connectors, swivel fittings rotate smoothly, helping maintain a consistent spray pattern and preventing hose wear. This improved flexibility means you can adjust your spray angle more easily, resulting in better coverage and efficiency. Traditional connectors often restrict movement, leading to more tension on the hose and potential damage over time. Swivel fittings keep your setup more durable and reliable, especially during prolonged use. Overall, they provide a simple upgrade that offers better control, longer hose life, and a more consistent spray pattern.

Common Industries and Use Cases for Swivel Fittings

Where are swivel fittings most commonly used? You’ll find them in various industries where flexibility and ease of movement matter. In garden irrigation, they help connect hoses without tangling, allowing for smooth watering around plants. For automotive fluid transfer, swivel fittings enable secure, leak-free connections that can handle vibrations and movement.

Swivel fittings are essential in garden, automotive, and manufacturing for flexible, leak-free connections.

Industries and use cases include:

- Garden irrigation systems for efficient watering

- Automotive fluid transfer for quick, secure connections

- Manufacturing plants where hoses need to move freely

- Food processing facilities requiring sanitary, flexible fittings

Troubleshooting Tips for Swivel Fittings

Even with their versatility, swivel fittings can sometimes present issues that disrupt their performance. If your hose coupling isn’t rotating smoothly, check for debris or dirt buildup and clean the fitting thoroughly. Tight or loose connections can cause leaks or instability; ensure all fittings are properly tightened but not over-tightened. If your spray nozzle isn’t swiveling freely, inspect for kinks or damage in the hose itself, as these can restrict movement. Also, verify that the swivel fitting is correctly seated and free of corrosion. Regular maintenance, like lubricating the swivel joint with a suitable lubricant, can prevent sticking. Addressing these common problems promptly keeps your spray equipment functioning smoothly, ensuring consistent, flexible spraying without interruptions.

Innovations and Future Trends in Swivel Fitting Technology

Advancements in swivel fitting technology are driving improved durability, ease of use, and functionality. Innovations like smart materials enable fittings to adapt to temperature changes and resist corrosion, extending lifespan. Ergonomic design focuses on user comfort, reducing strain during installation and adjustment. Future trends include integrating sensors for real-time performance feedback and developing lightweight yet sturdy components. Additionally, manufacturers are exploring:

- Smart materials that enhance flexibility and durability

- Ergonomic designs that improve grip and handling

- Modular fittings for customizable configurations

- Coatings that resist wear and chemical exposure

These developments aim to make swivel fittings more reliable, user-friendly, and adaptable to diverse applications, ensuring that you benefit from increased efficiency and longevity in your spraying tasks.

Tips for Choosing the Right Swivel Fitting for Your Needs

When selecting a swivel fitting, you need to take into account material compatibility to make sure it works with your system’s fluids and conditions. Think about the rotation range you require; some fittings offer more movement than others to fit your setup. Also, check the connection types available to match your existing equipment and ensure a secure fit.

Material Compatibility

Choosing the right swivel fitting depends heavily on its material compatibility with your system’s fluids and environment. You need to take into account how materials resist material corrosion over time, especially if exposed to harsh chemicals or moisture. Conduct compatibility testing to make sure the fitting won’t degrade or cause leaks.

Keep these factors in mind:

- The chemical composition of your fluids

- Environmental conditions like humidity or temperature

- The durability of the fitting material against corrosion

- Compatibility with existing system components

Selecting a fitting made from the right material minimizes risks of failure and extends the lifespan of your setup. Always verify material compatibility to prevent costly repairs and ensure reliable performance.

Rotation Range Options

Selecting the right swivel fitting involves considering its rotation range to match your system’s movement requirements. Rotation options vary, offering different degrees of flexibility enhancement. Some fittings provide 90-degree rotation, ideal for limited movement areas, while others offer full 360-degree rotation for maximum maneuverability. Think about how much movement your application needs; a wider rotation range prevents stress on hoses and reduces leaks. If your setup requires frequent directional changes, choose a swivel with greater rotation options. On the other hand, applications with minimal movement can benefit from a more limited rotation range to keep things simple. Matching the rotation range to your specific needs ensures superior flexibility and durability, making your spraying system more efficient and less prone to wear.

Connection Types Available

Understanding the different connection types available is essential for guaranteeing your swivel fitting integrates seamlessly with your system. Whether you’re working on garden irrigation or automotive hoses, selecting the right connection prevents leaks and improves performance. Common connection types include threaded, quick-connect, compression, and push-fit fittings. Threaded fittings are ideal for secure, permanent setups, while quick-connects allow for easy, tool-free assembly. Compression fittings provide a tight seal for high-pressure applications, and push-fit connectors are perfect for quick repairs or temporary setups. When choosing, consider compatibility with your hoses, ease of installation, and whether the fitting needs to withstand pressure or weather conditions. Matching the connection type to your specific needs ensures maximum flexibility and durability.

Frequently Asked Questions

Can Swivel Fittings Handle High-Pressure Spraying Applications?

You might wonder if swivel fittings can handle high-pressure spraying. Generally, they do, thanks to their pressure tolerance and material durability. High-quality swivel fittings are designed to withstand significant pressure, providing reliable performance without leaks or failure. Always check the specific pressure ratings and materials used, like stainless steel or reinforced plastics, to make certain they meet your spraying application’s demands. Proper selection guarantees durability and safety during high-pressure use.

Are Swivel Fittings Compatible With All Types of Hoses and Nozzles?

You might wonder if swivel fittings work with all hoses and nozzles. While they offer great hose compatibility, not all swivel fittings fit every hose or nozzle type. Check the fittings’ size and connection style to match your hose’s diameter and material. For nozzles, ensure the fitting’s connection type accommodates your spray nozzle. Proper matching guarantees a secure, leak-free connection, enhancing your spraying experience.

How Do Swivel Fittings Affect Spraying Accuracy and Precision?

Did you know that swivel fittings can improve spraying accuracy by up to 30%? They enhance rotation stability, allowing you to control spray direction more precisely. This means better spray consistency, reducing overspray and wastage. With improved stability, you can target surfaces more accurately, making your work more efficient. Swivel fittings help you maintain steady, precise control during spraying, giving you cleaner lines and a more professional finish every time.

What Maintenance Practices Extend the Lifespan of Swivel Fittings?

To extend the lifespan of swivel fittings, you should follow regular maintenance practices. Keep up with lubrication schedules to reduce friction and wear, ensuring smooth movement. Additionally, applying corrosion prevention measures, like protective coatings or anti-corrosion sprays, helps prevent rust and deterioration. Regular inspections for signs of damage or corrosion enable you to address issues early, maintaining peak performance and prolonging the fittings’ service life.

Are There Eco-Friendly or Recyclable Swivel Fitting Options Available?

Imagine transforming your entire watering setup into a green powerhouse—it’s possible! Eco-friendly materials and recyclable options for swivel fittings are now available, making your gardening or industrial tasks way more sustainable. You can choose fittings made from biodegradable plastics or recycled metals, drastically reducing waste and environmental impact. By opting for these eco-conscious options, you’re not just maintaining your equipment; you’re actively helping to protect the planet.

Conclusion

Swivel fittings are the keystones of flexible, efficient spraying. Like a trusted compass guiding your work, they steer your projects smoothly and adaptively. Embrace these fittings to release greater control and resilience in your tasks. When you choose the right swivel, you’re not just selecting a tool—you’re empowering your craft to flow effortlessly, transforming obstacles into opportunities. Let your choices turn the wheel of progress, steering you toward precision and success.