Are you a DIY enthusiast or a professional painter looking to improve the longevity of your airless paint sprayer? Look no further! This blog post provides you with five crucial tips for keeping your airless paint sprayer in top condition. From proper storage and protection against freeze damage to regular cleaning and using high-quality spare parts, these simple yet effective steps will help extend the lifespan of your reliable equipment. Join us as we delve into the top practices for greatly increasing the lifespan of your airless paint sprayer!

Store your airless paint sprayer properly

Proper storage is key when it comes to maintaining the lifespan of your airless paint sprayer. After a long day of painting, it can be tempting to simply toss your sprayer in a corner and call it a day. However, taking a few extra minutes to store it correctly will pay off in the long run.

Make sure that you clean your sprayer thoroughly before storing it. This includes flushing out any remaining paint and running water through the system until it runs clear. Neglecting this step can lead to clogged or damaged parts down the line.

Once cleaned, ensure that all components are completely dry before putting them away. Moisture left inside the sprayer can cause rust or corrosion over time, which can greatly affect its performance.

Next, find a cool and dry place for storage. Avoid areas with extreme temperatures or excessive humidity as these conditions can also damage your sprayer. Ideally, choose a well-ventilated space where the temperature remains relatively stable throughout the year.

Consider investing in a protective case or bag for your airless paint sprayer. This will provide an extra layer of safeguard against dust, debris, and accidental bumps during transportation or storage.

By following these simple steps and giving some thought to proper storage techniques, you’ll greatly extend the lifespan of your airless paint sprayer and ensure that it’s ready for action whenever you need it!

Protect your airless paint sprayer from freezing temperatures

Protecting your airless paint sprayer from freezing temperatures is crucial to extending its lifespan and ensuring optimal performance. When exposed to extreme cold, the paint sprayer’s components can freeze, causing damage and affecting its functionality.

To safeguard your equipment, it is important to store it in a climate-controlled environment when not in use. Avoid leaving it outside or in unheated spaces during winter months. If you must transport the paint sprayer during cold weather, make sure it is properly insulated with blankets or other protective materials.

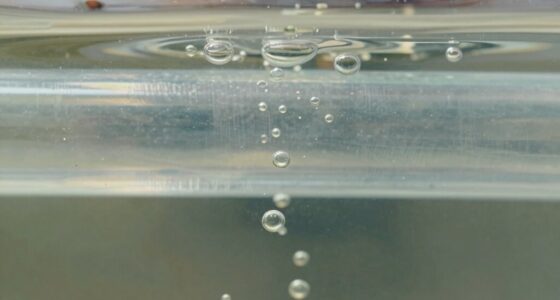

Before using the airless paint sprayer after storage in low temperatures, allow it to gradually warm up to room temperature. This will prevent any condensation from forming inside the machine and potentially damaging sensitive parts.

Another way to protect your airless paint sprayer from freezing temperatures is by using antifreeze solutions specifically designed for this purpose. These solutions help prevent water-based paints and coatings from freezing within the pump system.

Regular maintenance also plays a critical role in protecting your equipment from cold-related issues. Inspect hoses, fittings, and seals regularly for signs of wear or damage that could be exacerbated by freezing temperatures.

By taking these precautions and being mindful of extreme cold conditions, you can ensure that your airless paint sprayer remains protected and operates at peak performance throughout its lifespan!

Clean your airless paint sprayer regularly

Regular cleaning of your airless paint sprayer is essential to ensure its longevity and optimal performance. By keeping it clean, you can prevent clogs, blockages, and other issues that may arise during painting projects.

Always make sure to clean the spray gun after each use. This involves disassembling the gun and removing any excess paint or debris. Use a brush or cloth to wipe down all parts thoroughly before reassembling.

Additionally, don’t forget about the filters in your airless paint sprayer. These play a crucial role in preventing particles from entering and clogging the system. Regularly check and clean these filters according to the manufacturer’s instructions.

Furthermore, flushing out the entire system with water or an appropriate cleaning solution is highly recommended. This helps remove any residual paint or contaminants that may have accumulated inside the pump, hoses, and fittings.

Pay attention to the cleanliness of your storage area for the sprayer when not in use. A clean environment will help prevent dust or dirt from finding their way into critical components.

By implementing these regular cleaning practices for your airless paint sprayer, you can keep it running smoothly for years to come!

Use the correct type of oil in your airless paint sprayer

Using the correct type of oil in your airless paint sprayer is crucial for maintaining its lifespan and ensuring optimal performance. The right oil helps to minimize friction, reduce wear on internal components, and prevent corrosion.

When selecting the oil for your airless paint sprayer, it’s important to consult the manufacturer’s recommendations. Different models may require different types of oils or lubricants. Using the wrong type of oil can lead to damage and potentially void any warranties.

Typically, airless paint sprayers require a lightweight mineral-based oil that is specifically designed for high-pressure applications. These oils are formulated to withstand the intense pressures and temperatures generated by the pump system.

Regularly checking the oil level in your airless paint sprayer is also essential. Running an airless paint sprayer without enough oil can cause excessive heat buildup and premature wear on vital parts. It’s advisable to top up or change the oil as recommended by the manufacturer.

In addition to using the correct type of oil, following proper maintenance practices such as cleaning filters regularly and inspecting hoses for wear will further extend your airless paint sprayer’s lifespan.

By taking these precautions and using suitable oils, you can ensure that your airless paint sprayer operates at its best for years to come!

Use high-quality replacement parts in your airless paint sprayer

When it comes to maintaining the lifespan of your airless paint sprayer, using high-quality replacement parts is crucial. Whether it’s a nozzle, hose, or pump, investing in top-notch components will not only ensure optimal performance but also extend the longevity of your equipment.

One of the key benefits of using high-quality replacement parts is their durability. Cheap and low-quality parts may save you some money upfront, but they are more likely to wear out quickly and require frequent replacements. On the other hand, opting for premium parts means fewer repairs and less downtime on your projects.

Furthermore, high-quality replacement parts are designed to fit seamlessly with your airless paint sprayer. This ensures proper functionality and eliminates any potential leaks or malfunctions that could occur with incompatible or subpar components.

Another advantage of using top-notch replacement parts is improved efficiency. These parts are engineered to deliver precise spray patterns and consistent results. They can help you achieve a smooth finish while reducing overspray and wasted paint.

Reputable manufacturers often provide warranties for their high-quality replacement parts. This gives you peace of mind knowing that if anything goes wrong within the warranty period, you can get a free or discounted replacement without additional costs.

In conclusion (not concluding), investing in high-quality replacement parts for your airless paint sprayer is an investment in its long-term performance and reliability. With durable components that fit perfectly with your equipment, you’ll experience less downtime on repairs and maintenance while enjoying efficient painting results every time!

Conclusion

Taking proper care of your airless paint sprayer is essential for extending its lifespan and ensuring optimal performance. By following these top 5 tips, you can keep your equipment in great shape and avoid costly repairs or replacements.

Remember to store your airless paint sprayer properly, protecting it from extreme temperatures and potential damage. Regularly cleaning the unit will help prevent clogs and maintain efficient operation. Using the correct type of oil will keep the internal components lubricated and functioning smoothly.

Additionally, opting for high-quality replacement parts when needed will ensure that your airless paint sprayer continues to perform at its best for years to come.

By implementing these maintenance practices, you’ll not only save time but also money by avoiding unnecessary downtime or expensive repairs. So take good care of your airless paint sprayer, and enjoy reliable performance whenever you need it!

For any further assistance or information regarding airless paint sprayers, feel free to contact our team of experts who are always ready to assist you.

Remember: a well-maintained airless paint sprayer is a valuable tool that can make all your painting projects easier, more efficient, and enjoyable!