When painting ceilings with a Graco airless sprayer, choosing the right tip size is crucial for achieving a smooth and flawless finish. As someone who has tackled numerous ceiling painting projects, I understand the importance of getting this detail right.

In this article, I will guide you through the process of selecting the ideal tip size for your specific needs. We will explore the factors that should be considered when deciding on a tip size, such as the type of paint, the texture of the ceiling, and the desired coverage. I will provide you with recommended tip sizes for different types of ceiling painting projects, helping you make an informed decision.

Additionally, I will share tips on how to test and adjust the tip size to ensure optimal performance. We will discuss proper technique for using an airless sprayer on ceilings, as well as maintenance and cleaning tips for your sprayer tips.

Join me as we dive into the world of tip sizes and learn how to achieve professional results when painting ceilings with a Graco airless sprayer.

Key Takeaways

- Importance of correct tip size for optimal coverage and atomization

- Factors affecting tip size selection: distance between sprayer and ceiling, manufacturer’s guidelines

- Maintenance and cleaning of tips: regular cleaning, use of cleaning solution and brush/toothpick, inspect for wear or damage, proper storage

- Safety precautions: wear goggles, gloves, and respirator mask, work in well-ventilated area

Understanding the Importance of Tip Size in Airless Sprayers

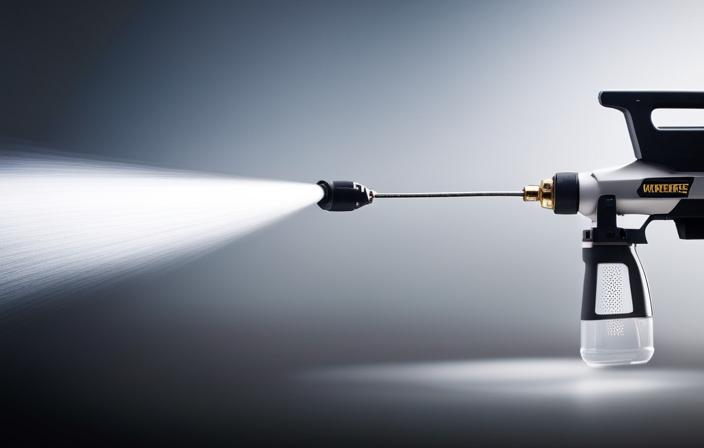

Choosing the right tip size for your Graco airless sprayer is crucial if you want to achieve flawless results and make your ceiling painting experience a breeze. The tip size determines the amount of paint being sprayed and the width of the spray pattern.

When it comes to painting ceilings, there are a few factors to consider before selecting the appropriate tip size. First, you need to assess the texture of your ceiling. For smooth ceilings, a smaller tip size, such as 0.015 inches, will work well. However, if your ceiling has a textured surface, a larger tip size, like 0.021 inches, may be more suitable.

Additionally, troubleshooting common issues like clogging or uneven spray can often be resolved by adjusting the tip size.

By considering these factors, you can ensure a smooth and efficient painting process.

Factors to Consider When Choosing the Right Tip Size

When deciding on the perfect tip for your Graco airless sprayer to paint the ceiling, take into account various factors that will ultimately determine the most suitable option. Factors to consider include the type of paint being used, the desired finish, and the size of the area to be painted.

-

Type of Paint: Different paints have different viscosity levels, which affect the flow rate of the paint. Thicker paints may require larger tip sizes to ensure proper atomization and coverage.

-

Desired Finish: If you want a smooth finish, a smaller tip size is recommended. For textured finishes, a larger tip size may be necessary.

-

Size of Area: The size of the area to be painted will also play a role in determining the best tip size. Larger areas may require larger tip sizes to increase productivity.

By considering these factors, you can choose the best tip size options for your ceiling painting project. Transitioning into the next section, let’s explore the recommended tip sizes for different ceiling painting projects.

Recommended Tip Sizes for Different Ceiling Painting Projects

When it comes to painting smooth and untextured ceilings, a tip size of 0.015 to 0.017 inches is recommended for optimal coverage and a smooth finish.

For lightly textured ceilings, a slightly larger tip size of 0.017 to 0.019 inches is advised to ensure that the paint reaches into the crevices and provides an even coat.

However, for heavily textured ceilings, a larger tip size of 0.021 to 0.025 inches is necessary to effectively cover the rough surface and avoid any missed spots.

Smooth and Untextured Ceilings

For smooth and untextured ceilings, you’ll want to use a specific tip size on your Graco airless sprayer. To achieve a flawless finish, it’s essential to choose the appropriate paint and avoid streaks.

A tip size of 0.015 to 0.017 inches is recommended for this type of ceiling. This size allows for a fine mist of paint to be evenly distributed, resulting in a smooth and professional-looking surface. Using a larger tip size may lead to excessive overspray and a less precise application.

As we transition to discussing lightly textured ceilings, it’s important to note that the tip size may need to be adjusted slightly to accommodate the texture.

Lightly Textured Ceilings

To achieve a ceiling with a subtle texture, you’ll want to make sure your paint application is as smooth as butter, creating a surface that’s as inviting as a gentle breeze.

To do this, it’s important to choose the right sprayer for the job. Look for a Graco airless sprayer with a tip size of 0.015 to 0.019 inches. This size will allow for a fine mist of paint that will evenly coat the ceiling without creating too much texture.

Before spraying, be sure to prepare the ceiling by cleaning it thoroughly and filling in any imperfections with spackle. Sanding the surface lightly will also help to create a smooth base for the paint.

With the right sprayer and proper preparation techniques, you’ll be well on your way to achieving a lightly textured ceiling that will add a touch of elegance to any room.

Now, let’s move on to heavily textured ceilings.

Heavily Textured Ceilings

When it comes to heavily textured ceilings, the right tip size is crucial for a successful paint job. The larger the texture, the larger the tip size needed to ensure proper coverage. To achieve the best results, I would recommend using a tip size of 0.021 to 0.025 inches on a Graco airless sprayer. This size will allow the paint to flow smoothly and evenly over the textured surface, minimizing the risk of clogging or uneven application.

When working with heavily textured ceilings, it is important to adjust your spraying technique accordingly. Keep the sprayer at a consistent distance from the surface, typically around 12 to 18 inches, and maintain a steady, overlapping motion to ensure even coverage. Additionally, always wear protective gear, such as goggles and a respirator, to protect yourself from any paint overspray.

Now that we’ve covered the tip size for heavily textured ceilings, let’s move on to the next step: testing and adjusting the tip size.

Testing and Adjusting the Tip Size

Discover the perfect tip size for effortlessly painting your ceiling with a Graco airless sprayer.

-

Testing Techniques: Begin by selecting a tip size based on the manufacturer’s recommendation. Test the spray pattern on a scrap piece of cardboard or a small section of the ceiling. Adjust the tip size if necessary to achieve a consistent and even spray pattern.

-

Optimal Spray Pattern: Look for a tip size that produces a fan-shaped spray pattern that covers the desired area without overspray. The pattern should be uniform and free from streaks or lines.

-

Fine-Tuning: If the spray pattern is too narrow or too wide, try a different tip size. Narrow patterns may result in uneven coverage, while wide patterns can cause excessive overspray.

To ensure proper technique for using an airless sprayer on ceilings, it’s important to understand the ideal tip size and how to adjust it for optimal results.

Proper Technique for Using an Airless Sprayer on Ceilings

Master the art of painting your ceiling effortlessly with an airless sprayer by following the proper technique and achieving flawless results.

The key to a successful ceiling paint job lies in using the right technique and ensuring even coverage. Start by positioning yourself directly beneath the area you’re painting, holding the sprayer at a 90-degree angle to the ceiling.

Use smooth, overlapping strokes in a consistent pattern, such as a straight line or a zigzag. Maintain a steady pace and keep the sprayer at a consistent distance from the surface. This’ll help prevent uneven coverage and drips.

By mastering the proper technique, you can achieve a beautifully painted ceiling with minimal effort.

Next, let’s explore troubleshooting common issues with tip size to ensure your painting project goes smoothly.

Troubleshooting Common Issues with Tip Size

Overcoming common issues with the size of your spray nozzle can make all the difference in achieving a flawless, professional-looking finish that’ll leave you feeling accomplished and proud of your painting skills. When troubleshooting common issues with tip size on a Graco airless sprayer for painting ceilings, there are a few key factors to consider.

First, make sure you’re using the correct tip size for the type of paint you’re using. Different paints require different tip sizes to achieve optimal coverage and atomization.

Second, check the condition of your tip. A worn or damaged tip can affect the spray pattern and result in an uneven finish.

Third, consider the viscosity of your paint. Thicker paints may require a larger tip size to prevent clogging.

Fourth, pay attention to the distance between the sprayer and the ceiling. Holding the sprayer too close or too far can impact the spray pattern.

Lastly, always refer to the manufacturer’s guidelines and recommendations for choosing the right tip size for your specific sprayer model.

By troubleshooting common issues with tip size, you can ensure a smooth and efficient painting process.

In the next section, we’ll discuss maintenance and cleaning tips for airless sprayer tips, which are crucial for prolonging their lifespan and maintaining optimal performance.

Maintenance and Cleaning Tips for Airless Sprayer Tips

Ensure that you properly maintain and clean your airless sprayer tips to maximize their lifespan and keep them performing at their best, so you can achieve flawless, professional results that will leave you feeling confident and satisfied with your painting projects.

To ensure optimal performance, it’s important to regularly clean your airless sprayer tips. After each use, remove the tip and soak it in a cleaning solution to remove any paint residue. Use a small brush or toothpick to gently clean out any clogs or debris. Additionally, inspect the tip for any signs of wear or damage, and replace it if necessary.

Proper storage is also important to prevent tip damage. Store your tips in a clean, dry place to avoid any corrosion or buildup.

By following these maintenance tips and cleaning techniques, you can keep your airless sprayer tips in excellent condition for longer-lasting performance.

Now, let’s move on to discussing the safety precautions when using an airless sprayer.

Safety Precautions When Using an Airless Sprayer

When it comes to using an airless sprayer, safety should always be a top priority. Before getting started, it’s important to take the necessary precautions to protect yourself and those around you. This includes wearing the appropriate safety gear, such as goggles, gloves, and a respirator mask. Additionally, make sure you are working in a well-ventilated area to avoid inhaling harmful fumes.

To provide a visual representation of the recommended safety gear and proper ventilation, I have created a table below:

| Safety Gear | Proper Ventilation |

|---|---|

| Goggles | Open windows |

| Gloves | Use a fan |

| Respirator | Ensure airflow |

By following these safety precautions, you can minimize the risks associated with using an airless sprayer. In the next section, we will address some frequently asked questions about tip size for ceiling painting. But first, let’s talk about the importance of selecting the right tip size for the job.

Frequently Asked Questions about Tip Size for Ceiling Painting

Let’s dive into some frequently asked questions about choosing the right nozzle for painting ceilings! When it comes to tip size for ceiling painting with a Graco airless sprayer, there are some common mistakes to avoid and best practices to follow.

One common mistake is using a tip size that’s too small, which can result in a patchy and uneven paint job. It’s recommended to use a larger tip size, such as a 0.015 or 0.017, to ensure proper coverage and a smooth finish.

Another best practice is to hold the sprayer nozzle at a consistent distance from the ceiling, typically around 12 inches. This helps to maintain an even spray pattern and prevent drips or overspray.

By choosing the right tip size and following these best practices, you can achieve a professional-looking ceiling paint job with your Graco airless sprayer.

Now, let’s move on to the conclusion and final tips for successful ceiling painting with an airless sprayer.

Conclusion and Final Tips for Successful Ceiling Painting with an Airless Sprayer

To achieve a professional finish on your ceiling, it’s important to select the right nozzle and maintain a consistent distance from the surface. When using a Graco airless sprayer, testing and adjusting the tip size is crucial for optimal results. Here are some final tips for successful ceiling painting with an airless sprayer:

-

Testing and Adjusting:

Before starting your project, test the spray pattern and adjust the tip size accordingly. Begin with a smaller tip size and gradually increase until you achieve the desired coverage and finish. -

Troubleshooting Tip Size:

If the paint is splattering or dripping, the tip size may be too large. Try reducing the tip size and test again. On the other hand, if the paint is not covering the surface evenly, the tip size may be too small. Increase the tip size and test for better results.

By following these tips and properly testing and adjusting the tip size, you can ensure a smooth and professional ceiling painting experience with your Graco airless sprayer.

Frequently Asked Questions

Can I use the same tip size for all types of ceiling surfaces?

Sure, you can use the same tip size for all ceiling surfaces if you enjoy streaky, uneven paint jobs. However, using a larger tip size offers benefits like faster coverage and smoother finishes.

Are there any specific tip sizes recommended for textured ceilings?

For textured ceiling painting, it is recommended to use a larger tip size to ensure adequate coverage and minimize clogging. The best tip size for ceilings is typically between 0.017 to 0.023 inches.

How do I know if the tip size I am using is too small or too large for my project?

To choose the right tip size for different projects, consider the material being sprayed, the desired finish, and the sprayer’s pressure rating. Maintaining and cleaning sprayer tips regularly will help ensure optimal performance and prevent clogs.

Can I adjust the spray pattern by changing the tip size?

Yes, changing the tip size on a Graco airless sprayer can help adjust the spray pattern. By selecting a different tip size, you can achieve a wider or narrower spray for more precise and efficient coverage.

Are there any safety precautions I should take when using a larger tip size?

When using a larger tip size on a Graco airless sprayer, there are several safety precautions to take. It is important to wear proper safety equipment such as goggles and gloves to protect yourself from overspray and paint splatter.

Conclusion

In conclusion, choosing the right tip size for your graco airless sprayer is crucial for achieving a flawless ceiling paint job. By considering factors such as the type of paint, surface texture, and desired coverage, you can select the optimal tip size. Testing and adjusting the tip size may be necessary to ensure proper paint flow.

Remember to use proper technique and follow safety precautions when using the sprayer. With regular maintenance and cleaning, your airless sprayer will continue to deliver professional results.

Happy painting!