When using an airless paint sprayer, you need to prioritize your safety with the right protective gear. Start with a properly fitted respirator to guard your lungs against harmful fumes. Wear safety goggles to protect your eyes from overspray and splashes. Nitrile gloves are essential to keep your hands safe from irritants and chemicals. A durable coverall can shield your skin and clothing from paint, while knee pads provide comfort during extended periods of work. These precautions help minimize risks. Stick around to discover more about specific safety protocols and emergency procedures essential for your protection.

Key Takeaways

- A properly fitted respirator is essential to protect against harmful fumes and inhalation risks during airless painting.

- Safety goggles or face shields prevent serious eye injuries from overspray and should meet ANSI Z87.1 standards.

- Nitrile gloves provide chemical resistance, safeguarding hands from irritation and hazardous materials.

- Durable protective coveralls shield skin and clothing from paint splatters while allowing for mobility.

- Knee pads offer comfort and support, reducing the risk of injury during extended kneeling tasks.

Common Risks of Airless Painting

When using airless paint sprayers, you need to be aware of several common risks that can arise during the process. One of the most notable dangers is the potential for severe injection injuries. The high pressure at which these sprayers operate can cause paint to penetrate your skin, necessitating immediate medical attention.

To mitigate this risk, it's vital to practice proper spraying techniques and maintain a safe distance from the spray tip. Additionally, inhaling harmful paint fumes and volatile organic compounds (VOCs) is a real concern, so proper respiratory protection is imperative, especially when working on larger surfaces as mentioned in airless paint sprayer basics.

Eye injuries from overspray are also common; that's why you must wear protective eyewear to shield your eyes from splashes and irritation. Falls from ladders or scaffolding can lead to serious accidents, making it essential to use fall arrest gear and follow proper ladder safety protocols.

To greatly reduce the likelihood of injuries, make sure you receive proper training and adhere to safety protocols throughout the airless painting process. By being aware of these risks and taking the necessary precautions, you can enhance your protection and guarantee a safer working environment.

Essential Personal Protective Equipment

When you're using an airless paint sprayer, having the right personal protective equipment (PPE) is essential for your safety.

For instance, understanding the importance of maintaining equipment can help guarantee that your sprayer operates effectively and safely, minimizing the risk of accidents.

You need to select quality gear like respirators, goggles, and gloves to shield yourself from harmful substances.

Regular inspections and maintenance can also prevent potential hazards associated with improper functioning of tools, as seen in HVAC maintenance.

Let's explore the key items you should always have on hand.

Key PPE Items

Using the right personal protective equipment (PPE) is essential for your safety when operating an airless paint sprayer. Here are some key items you'll need:

| PPE Item | Purpose | Recommendation |

|---|---|---|

| Respirator | Filters harmful fumes and particulates | Must meet OSHA standards |

| Eye Protection | Prevents serious eye injuries from splashes | Use safety goggles or face shields |

| Nitrile Gloves | Protects hands from hazardous materials | Chemical-resistant is best |

| Protective Coveralls | Safeguards skin and clothing from overspray | Choose durable, chemical-resistant suits |

| Knee Pads | Provides support when working on lower areas | Opt for cushioned, supportive options |

Selecting Quality Gear

Selecting quality gear for your airless paint spraying tasks is vital to guarantee your safety and comfort. Using the right protective gear not only shields you from harmful fumes and paint splatters but also assures you can work efficiently.

Additionally, investing in equipment that meets safety standards is essential for minimizing risk while performing tasks. Here are some must-have items to take into account:

- High-quality respirators that meet OSHA standards

- Chemical-resistant safety goggles or face shields

- Nitrile or chemical-resistant gloves

- Breathable coveralls for comfort and protection

- Regularly inspected and replaced PPE

When spray painting, prioritize a respirator that effectively filters out harmful particulates and fumes. Your eye protection should be rated for chemical resistance to guard against splashes and vapor exposure.

Don't overlook the importance of gloves; they'll prevent skin irritation and hazardous material absorption. Opt for coveralls made from breathable materials that allow for movement while providing a barrier against paint irritants.

Finally, make it a habit to regularly inspect your personal protective equipment (PPE) to maintain effectiveness and secure a fit. By investing in quality gear, you can create a safer, more comfortable working environment while spray painting.

For further information, think about looking into home cleaning service costs to guarantee you're budgeting appropriately for safety.

Understanding Spray Painting Hazards

When you're spray painting, it's vital to recognize the hazards you face, especially inhalation risks from airborne particulates and harmful fumes.

Using air purifiers can greatly enhance indoor air quality and reduce these risks, making it safer to work in enclosed spaces.

Skin exposure can also lead to serious health issues, so protecting your skin is essential.

Don't forget about your eyes; they need proper protection to shield against splatters and irritants.

Inhalation Risks

Inhalation risks during spray painting can't be overlooked, as aerosolized paint particulates can penetrate deep into your lungs, leading to serious respiratory issues.

It's crucial to understand the hazards associated with inhaling harmful vapors and to take necessary precautions. Using air purifiers, especially those designed to reduce VOCs, can greatly improve air quality in your workspace, helping to mitigate these risks.

air quality indicators can be useful for monitoring the effectiveness of your air purification efforts.

- Volatile organic compounds (VOCs) can cause throat irritation and long-term health problems.

- Inhalation of paint fumes may lead to kidney damage over time.

- OSHA requires the use of respirators during spray painting to safeguard your health.

- Proper ventilation is critical to reduce the concentration of harmful airborne substances.

- Regular air quality monitoring can help identify potential inhalation risks.

Ignoring these risks could result in considerable health consequences.

To protect yourself, always wear a suitable respirator and confirm your workspace is well-ventilated. By remaining vigilant about inhalation risks, you can create a safer environment for yourself and others involved in the painting process.

Don't underestimate the importance of safety gear; your health is worth the investment.

Skin Exposure Hazards

While inhalation risks are a major concern in spray painting, skin exposure hazards pose significant threats as well. When you're working with aerosolized spray paint, fine particulates can easily settle on your skin, leading to irritation, allergic reactions, or even chemical burns due to volatile organic compounds (VOCs) and other harmful substances in the paint.

To enhance your overall well-being and safety during the painting process, consider implementing visible security measures in your workspace, which can deter potential accidents and guarantee a safer environment.

To protect yourself, wearing appropriate protective gear is vital. Nitrile or chemical-resistant gloves are a must to prevent direct skin contact with hazardous materials. Additionally, verify you're using coveralls to shield your body from any overspray.

It's also imperative to maintain proper ventilation in your spray area. This helps minimize the risk of harmful fumes that can permeate your clothing and irritate your skin.

Regularly check and maintain your protective equipment to confirm it remains effective. Worn or damaged gloves and coveralls can compromise your safety, leaving you vulnerable to skin exposure hazards.

Eye Protection Importance

During spray painting, eye protection is essential to guard against the fine mist and particles that can irritate or seriously harm your eyes.

Without proper safety measures, you risk exposure to harmful chemicals and paint splashes that could lead to injuries.

It's vital to guarantee that your disposal practices are also safe and environmentally friendly, as improper disposal can have significant consequences on plumbing and local ecosystems, similar to the issues seen with flushing improper items.

Consider these critical points about eye protection:

- Aerosolized paint can create a fine mist that easily reaches your eyes.

- Safety goggles or face shields are effective barriers against paint and chemicals.

- Confirm your eye protection meets or exceeds ANSI Z87.1 standards as per OSHA regulations.

- Long-term exposure to spray paint fumes can lead to severe eye health issues.

- Proper safety gear minimizes the risk of chemical burns from volatile organic compounds (VOCs).

Recommended Safety Gear

When using an airless paint sprayer, wearing the right safety gear is essential to protect yourself from potential hazards. Start with a properly fitted respirator to shield your lungs from harmful fumes and airborne particulates produced during spray painting.

In addition, understanding the importance of safety gear is paramount in various fields, including cybersecurity measures. Next, make sure you have protective eyewear, such as safety goggles, to prevent eye injuries caused by overspray or accidental fluid contact.

Nitrile or chemical-resistant gloves are a must to safeguard your hands from skin irritation and the absorption of hazardous chemicals found in paints and solvents. Coveralls and shoe covers will help keep your skin and clothing protected from paint splatters and spills, which also contributes to a cleaner work environment.

If you're working in low areas, consider using knee pads. They'll provide cushioning and prevent discomfort or injury during extended periods of kneeling while painting.

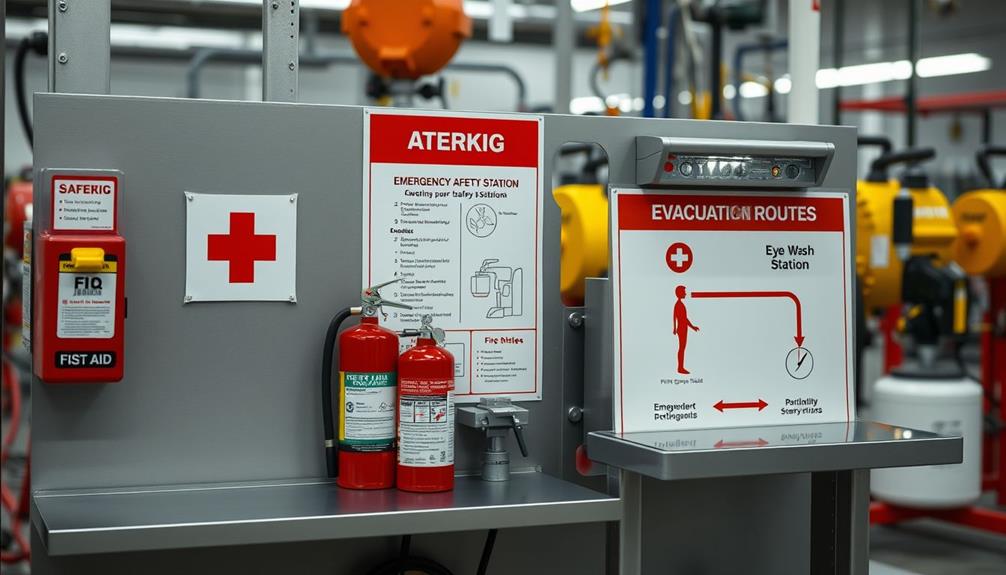

Emergency Procedures and Response

Even with the best safety gear, accidents can happen, so it's vital to know what to do in an emergency. Keeping a clear plan in mind can greatly reduce the risks associated with airless paint sprayers. This is especially important as stress from such incidents can exacerbate mental health issues, making it important to support emotional well-being during emergencies mental health support.

- Always have a first aid kit on hand.

- Know the location of the nearest emergency facility.

- Inform your team about emergency contact numbers.

- Monitor for symptoms of injection injuries after an incident.

- Practice trigger safety to avoid accidents.

If you suspect a high-pressure fluid injection injury, seek immediate medical attention. These injuries can lead to severe complications if not treated promptly.

Make sure to inform medical staff about the possibility of a high-pressure injection and provide details about the paint or coating involved. This information is important for appropriate treatment.

Surgical intervention, including decompression and debridement, is often necessary for injection injuries. Symptoms mightn't appear immediately, so vigilance is key after any incident.

Always have emergency response procedures in place and be ready to provide first aid before professional help arrives. Being prepared can make all the difference in ensuring your safety and recovery.

Maintenance of Safety Equipment

Regular maintenance of your safety equipment is essential for guaranteeing a safe working environment with airless paint sprayers.

Start by regularly inspecting hoses and connections for leaks, making sure they're free from damage. This simple check can prevent accidents during use.

It's also important to maintain an updated operator's manual for your equipment, as it contains significant safety instructions and maintenance guidelines.

Additionally, consider top safety gear options that can enhance your protection during painting tasks.

Follow the manufacturer's recommendations for flushing and cleaning your sprayer to prolong its lifespan and guarantee safe operation.

Keep metal guards and safety devices in place to prevent accidental activation of the trigger when the sprayer isn't in use.

Additionally, schedule routine maintenance checks to verify that all safety equipment, like pressure relief valves and safety goggles, are functioning properly before starting any job.

Resources for Safety Gear

Maintaining safety equipment is just the first step in guaranteeing a safe painting environment. To fully protect yourself during airless paint spraying, you need access to reliable resources for safety gear.

Understanding the importance of quality assurance in your safety practices can greatly enhance your protection (importance of quality assurance). Here are some essential items you should consider:

- Respirators to filter harmful fumes

- Protective eyewear to shield your eyes from overspray

- Heavy-duty gloves to protect your hands

- Coveralls or protective clothing to keep your skin safe

- Safety data sheets (SDS) for paint and coatings

Home Depot is a great place to find a wide range of safety equipment specifically designed for painting projects. You can order online and enjoy convenient delivery options, guaranteeing you get your gear quickly.

If you're unsure about what you need, don't hesitate to reach out to their support team via phone or text for guidance on the right equipment for your specific airless painting tasks.

Additionally, signing up for email newsletters can provide you with valuable discounts and tips on safe painting practices. Stay informed about the latest safety gear and protocols to guarantee a safer working environment.

Frequently Asked Questions

What Personal Protective Equipment Is Needed for Spray Painting?

When spray painting, you'll need a high-quality respirator, protective eyewear, nitrile gloves, and coveralls. Don't forget knee pads for comfort during extended kneeling. These items guarantee your safety and prevent irritation from paint exposure.

What PPE Must Be Worn in a Paint Spray Booth?

Entering a paint spray booth is like stepping into a storm; you need protection. Wear a fitted respirator, safety goggles, chemical-resistant gloves, and coveralls to shield yourself from harmful fumes and splashes.

Do I Need a Respirator for Airless Sprayer?

Yes, you need a respirator for an airless sprayer. It protects you from harmful fumes and particles. Make certain it's properly fitted and rated for the specific coatings you're using to guarantee maximum safety.

What Are the Hazards of Airless Paint Sprayer?

When using an airless paint sprayer, you face hazards like high-pressure fluid injection injuries, respiratory risks from VOC inhalation, accidental discharges, and the potential for static charge buildup, which could lead to explosive fire hazards.

Conclusion

In the world of airless painting, safety isn't just a precaution; it's your shield, much like a knight's armor in battle. By equipping yourself with the right protective gear, you're not just following guidelines—you're ensuring your own safety and well-being. Remember, every stroke counts, and so does your health. So, gear up and face the canvas with confidence, knowing you've taken the necessary steps to protect yourself from the hidden dangers lurking in the paint.