To dial in your perfect pattern with inline pressure gauges, you need to select the right type for your application, considering pressure range, material, and environment. Proper installation guarantees accurate readings and easy maintenance, while choosing digital or analog models depends on your monitoring needs. Regular checks help prevent issues like leaks or overpressure. Keep these tips in mind to maximize performance—continue exploring to discover how to fine-tune your setup for ideal results.

Key Takeaways

- Assess your application’s pressure range and environment to select the most suitable inline gauge material and design.

- Choose between analog or digital models based on your need for real-time readings, data logging, or remote monitoring.

- Ensure proper installation for accurate readings and easy maintenance, including correct pipeline integration and accessibility.

- Regularly calibrate and inspect gauges to maintain accuracy and prevent process hazards like overpressure.

- Consider space constraints and process requirements to select compact, durable gauges that withstand harsh conditions.

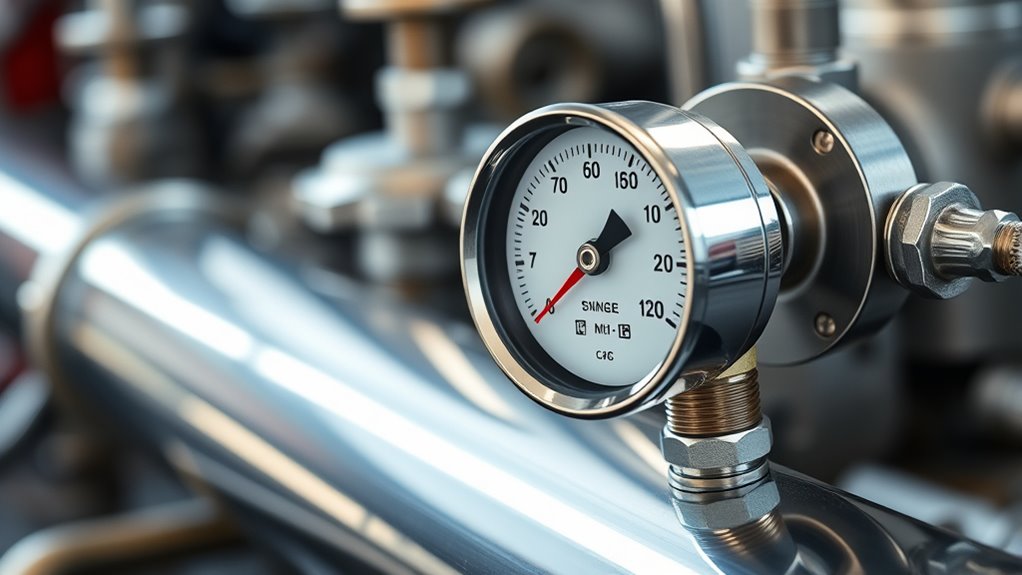

Have you ever wondered how industries monitor fluid pressure accurately in real-time? It’s a vital aspect of many operations, ensuring safety, efficiency, and quality control. Inline pressure gauges are the tools that make this possible. These devices are designed to be integrated directly into pipelines, providing immediate readings without disrupting the flow or process. When you install an inline gauge, you’re equipping yourself with a reliable, continuous stream of data that helps you maintain ideal conditions.

Unlike traditional gauges that sit outside the system, inline pressure gauges are built to withstand the harsh environments and high pressures common in industrial settings. They’re constructed with durable materials, ensuring longevity and consistent performance. As fluid flows through the pipeline, the gauge’s internal mechanism responds to pressure changes, translating them into a readable dial or digital display. This real-time feedback allows you to detect fluctuations instantly, whether it’s a drop indicating a leak or a spike suggesting a blockage.

Built to withstand harsh environments, inline gauges deliver reliable, real-time pressure readings in demanding industrial settings.

One of the key advantages of inline pressure gauges is their ability to provide ongoing, accurate measurements without needing frequent removal for calibration. This continuous monitoring helps prevent costly downtime or equipment failure. When you keep a close eye on pressure levels, you can troubleshoot issues early, adjust processes on the fly, and avoid the risks associated with overpressure or underpressure conditions.

Choosing the right inline pressure gauge depends on your specific application. Factors like pressure range, fluid type, temperature, and the environment all influence the best choice. For example, if you’re working with corrosive chemicals, you’ll want a gauge made from resistant materials like stainless steel or brass. If space is limited, compact designs are available that still provide precise readings. Digital models may offer additional features like data logging and remote monitoring, making them ideal for modern, automated systems.

Installation is straightforward but essential. Ensuring the gauge is properly integrated into the pipeline, sealed tightly, and positioned for easy viewing will maximize its effectiveness. Regular maintenance, such as checking for leaks or calibration, keeps your pressure readings trustworthy over time. Remember, an inline pressure gauge isn’t just a measurement tool; it’s an essential component of your control system that helps you fine-tune your process, avoid hazards, and achieve perfect operational patterns. Proper selection and maintenance of these gauges can enhance safety and optimize your overall system performance.

Frequently Asked Questions

How Do I Calibrate an Inline Pressure Gauge?

To calibrate an inline pressure gauge, you should first compare its readings with a known, accurate standard. Attach the gauge to a calibration device or pressure source, then apply incremental pressure, noting the gauge’s readings at each point. Adjust the calibration screw or knob if your gauge has one, ensuring it matches the standard. Repeat the process until your gauge consistently reads accurately across the desired pressure range.

What Is the Maximum Pressure Rating for These Gauges?

The maximum pressure rating for these gauges typically ranges from 150 to 3000 psi, depending on the model. Don’t put all your eggs in one basket; always check the specifications before using it in high-pressure applications. Exceeding the rated pressure can cause damage or inaccurate readings. To keep things running smoothly, select a gauge with a rating that comfortably exceeds your system’s maximum pressure.

Are There Specific Gauges Suitable for Corrosive Environments?

Yes, you should look for gauges made with corrosion-resistant materials like stainless steel or plastic, especially if you’re working in corrosive environments. These gauges are designed to withstand harsh chemicals and moisture, ensuring accurate readings and durability. Make sure to check the specifications to confirm they’re rated for your specific conditions. Using the right gauge will help you maintain safety and performance in challenging environments.

How Often Should I Replace or Service My Pressure Gauge?

You should replace or service your pressure gauge annually or whenever it shows signs of wear, inaccuracy, or damage. Regular inspections help catch leaks, corrosion, or stuck needles early. You also want to recalibrate periodically to guarantee precise readings. Keep an eye on your gauge, listen for leaks, and watch for sluggish movement—these signs indicate it’s time for maintenance or replacement, ensuring safe and accurate operation.

Can Inline Pressure Gauges Be Used for Liquid Measurements?

Yes, inline pressure gauges can be used for liquid measurements. They’re designed to handle liquids as long as you select one compatible with your specific fluid’s pressure and temperature requirements. Make sure the gauge’s materials are suitable to prevent corrosion or damage. Regularly check for leaks or damage, and calibrate the gauge periodically to ensure accurate readings, especially in critical liquid systems.

Conclusion

Now that you know how inline pressure gauges work, you’ll never have to guess again—you’re basically a pressure-measuring superhero! With the right dial, you can spot issues faster than a speeding bullet and keep your systems running flawlessly. Don’t settle for guesswork or subpar readings; these gauges are your secret weapon for precision and safety. Get yours today and turn your pressure monitoring into an effortless, pinpoint science—because your projects deserve nothing less than perfection!