To maintain hoses and spray guns for a long life, regularly inspect for cracks, leaks, or damage, and clean them thoroughly after each use with suitable solutions. Store hoses loosely coiled on a reel or hook to prevent kinks and stress. For spray guns, calibrate regularly and disassemble for detailed cleaning to avoid clogs. Proper handling and upkeep prevent issues and prolong equipment life—continue exploring expert tips to maximize your tools’ performance over time.

Key Takeaways

- Store hoses loosely coiled on a sturdy reel or hook to prevent kinks and stress.

- Regularly inspect hoses for cracks, leaks, or frays and replace damaged sections promptly.

- Clean hoses after use with appropriate solutions to remove debris and residual materials.

- Calibrate spray guns regularly to ensure even application and prevent clogging or overspray.

- Thoroughly clean spray guns after each use to prevent clogging and maintain optimal performance.

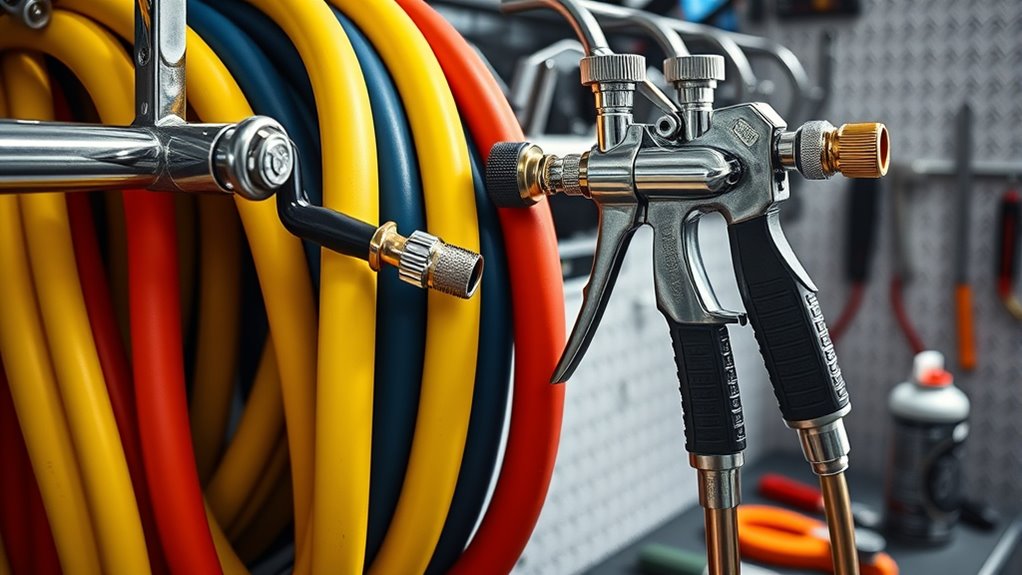

Maintaining your hoses and spray guns is essential to guarantee they perform effectively and last longer. Proper care directly impacts hose durability, ensuring that your equipment withstands regular use without cracking, leaking, or losing flexibility. One of the most effective ways to extend the life of your hoses is to avoid kinks and sharp bends, which can weaken the material over time. Always store hoses properly by coiling them loosely and hanging them on a sturdy reel or hook, preventing unnecessary stress on the hose structure. Regularly inspect your hoses for signs of wear, such as cracks, frays, or leaks, and replace damaged sections immediately to prevent further deterioration. Keeping your hoses clean from debris and residual material also plays a crucial role in maintaining their integrity. Rinsing them with water after each use, especially when working with harsh chemicals or paints, helps prevent buildup that can compromise hose flexibility and performance. Additionally, proper maintenance of hoses and spray guns can help prevent common issues like clogging or pressure loss.

When it comes to spray guns, calibration is a critical step that directly influences spray quality and efficiency. Proper spray gun calibration ensures an even, consistent application of coatings, reducing waste and improving the final finish. Regularly checking and adjusting the spray pattern, fluid flow, and air pressure according to manufacturer specifications keeps your spray gun operating at peak performance. Neglecting calibration can lead to uneven spray patterns, clogging, or excessive overspray, all of which diminish your work quality and put unnecessary strain on the equipment. Before each project, take a few minutes to verify that your spray gun is calibrated correctly—this small step can markedly extend its lifespan. Additionally, clean the spray gun thoroughly after each use, disassembling parts as needed to remove paint residues or blockages. Use appropriate cleaning solutions recommended by the manufacturer, and avoid using abrasive tools that could damage delicate components.

Frequently Asked Questions

How Often Should Hoses and Spray Guns Be Inspected?

You should inspect hoses and spray guns at least once a week to catch wear and tear early. Regular inspection helps you identify cracks, leaks, or worn-out parts before they cause failure. After heavy use or exposure to harsh conditions, increase inspection frequency to guarantee everything stays in top shape. Staying proactive saves you time and money by preventing unexpected breakdowns and extending the lifespan of your equipment.

Can I Repair Hoses Instead of Replacing Them?

Yes, you can repair hoses instead of replacing them to extend their durability. Use proper repair techniques like patching small leaks or reinforcing weak spots with suitable materials. However, assess the damage carefully; if the hose has extensive wear or multiple leaks, replacement might be more cost-effective. Regular inspections help identify issues early, ensuring your hoses maintain peak durability and performance over time.

What Are the Best Storage Practices for Hoses and Spray Guns?

Did you know that improper storage can reduce hose lifespan by up to 50%? To prevent this, always practice proper storage by hanging hoses and spray guns in a cool, dry place away from direct sunlight. Use environmental protection measures like covering them with breathable covers to shield from dirt and moisture. This keeps your equipment in top condition, ensuring durability and reliable performance every time you use them.

Are There Specific Cleaning Agents Recommended for Maintenance?

You should use cleaning agents that are chemical compatible with your hoses and spray guns to prevent damage. Eco-friendly cleaners are a great choice because they’re effective and safer for the environment. Always follow the manufacturer’s instructions for dilution and application, and guarantee thorough rinsing afterward. Regular cleaning with suitable, compatible cleaners helps maintain peak performance and extends the lifespan of your equipment.

How Do I Identify Early Signs of Hose or Spray Gun Failure?

Oh, the thrill of discovering your hose material or spray gun ergonomics are failing before the big job! Look for cracks, bulges, or leaks in hoses, and listen for unusual noises or inconsistent spray patterns. If your spray gun feels awkward or requires extra effort, it’s a clear sign. Catch these early signs, and you’ll save yourself from messy mishaps and costly replacements, proving you’re a true maintenance maestro.

Conclusion

By taking the time to properly maintain your hoses and spray guns, you’re giving them the gift of longevity, like tending a delicate garden to see it flourish. Regular inspections, cleaning, and careful storage are your best tools for keeping these essential items in top shape. Think of your maintenance routine as the steady hand that keeps your equipment running smoothly, ensuring you get the most out of every use and avoiding costly repairs down the line.