Understanding how nozzles, fans, and flow patterns work reveals the physics behind efficient airflow control. Nozzles accelerate fluids by shaping them to convert pressure into high velocity, while fans impart momentum to move air effectively. Flow patterns, determined by design, influence turbulence and precision. Together, these elements rely on principles like conservation of energy to optimize performance. If you explore further, you’ll uncover how these systems collaborate to create powerful, targeted flows across many applications.

Key Takeaways

- Nozzles shape fluid flow to accelerate it, converting pressure energy into velocity, crucial for precise and efficient fluid delivery.

- Fans generate airflow by imparting momentum, with blade design and speed affecting efficiency and airflow pattern control.

- Flow patterns are influenced by nozzle and blade design, affecting turbulence, energy loss, and targeted delivery or mixing.

- Physics principles like conservation of mass and energy govern how nozzles and fans optimize pressure-to-velocity conversion and flow behavior.

- Combining nozzles, fans, and flow patterns enhances system performance by controlling airflow, reducing turbulence, and maximizing efficiency.

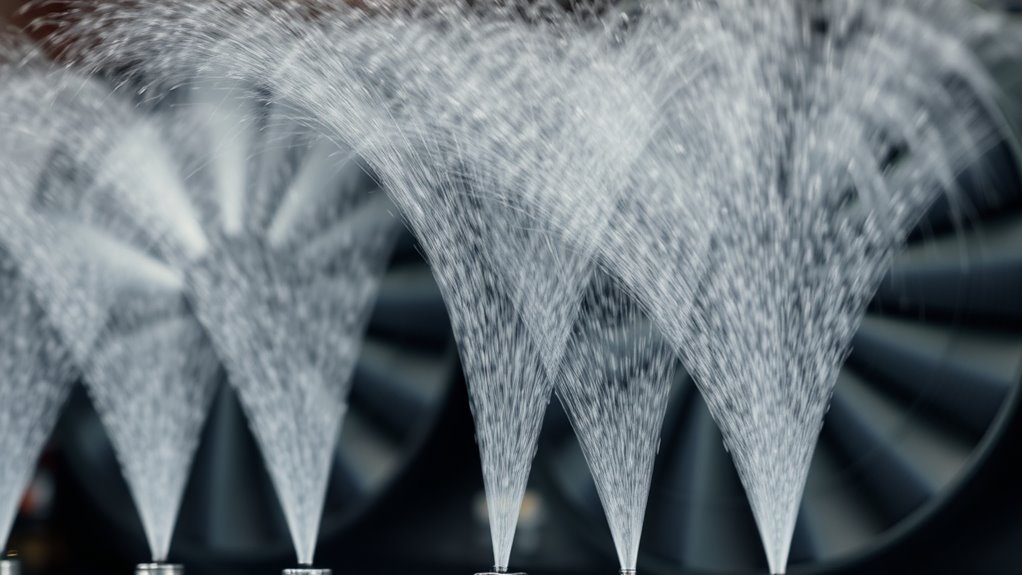

Nozzles, fans, and patterns work together to control airflow and optimize performance in various systems. When you understand how these elements interact, you can better predict and influence the behavior of fluids and gases in different applications. Nozzles, for example, are designed to accelerate fluids, turning pressure energy into kinetic energy, which results in high-velocity jets. This acceleration is governed by the principles of fluid dynamics, specifically the conservation of mass and energy. When you change the shape or size of a nozzle, you alter how efficiently it converts pressure into velocity. A narrow or tapered nozzle, for instance, produces a focused, high-speed jet, which is essential in applications like jet engines or spray nozzles. The design of the nozzle directly impacts the flow pattern and efficiency, making it a critical component in fluid systems. Fans, on the other hand, generate airflow by imparting momentum to the surrounding air. They create pressure differences that move air through ducts, openings, or across surfaces. When you select the right fan, you consider factors like airflow rate, pressure head, and efficiency. A powerful fan can move large volumes of air quickly, but it also consumes more energy. The design of the blades, their angle, and rotation speed influence how effectively a fan moves air and how much noise it produces. Combining a fan with a properly designed nozzle can markedly increase the velocity and focus of the airflow, making systems more efficient and effective. Patterns, whether they’re created by the shape of a nozzle or the arrangement of blades on a fan, are essential in controlling how airflow interacts with surfaces or targets. For example, a well-designed pattern ensures that airflow is evenly distributed or directed to specific areas, reducing turbulence and energy loss. When you work with patterns in fluid flow, you’re essentially shaping the flow path to achieve desired outcomes—like creating a laminar flow for precision or a turbulent one for mixing. The physics behind these patterns depends on fluid properties, boundary conditions, and geometry. Understanding how flow patterns develop helps you optimize systems for better cooling, propulsion, or even artistic effects. Additionally, advancements in fluid dynamics research have led to more sophisticated designs that maximize efficiency and performance. In practice, combining nozzles, fans, and patterns allows you to finely tune airflow for maximum efficiency and performance. Whether you’re designing a jet engine, a ventilation system, or a spray application, knowing how these elements interact keeps your system operating smoothly. By applying the physics principles behind each component, you can troubleshoot issues, improve designs, and achieve the desired finish or outcome with precision.

Frequently Asked Questions

How Do Temperature Changes Affect Airflow Dynamics?

Temperature changes directly impact airflow dynamics by altering air density and viscosity. When you heat the air, it becomes less dense and flows more easily, increasing velocity and reducing resistance. Conversely, cooling the air makes it denser and more viscous, slowing down airflow and increasing drag. These shifts influence how effectively air moves around objects, affecting everything from ventilation systems to aerodynamic designs.

Can Nozzle Shape Alter Spray Precision?

You might think nozzle shape has little impact on spray precision, but it actually plays a vital role. A well-designed nozzle directs airflow more accurately, producing a consistent, fine spray. By customizing the shape—like tapering or narrowing it—you can improve atomization and target specific areas. This precision reduces waste, enhances finish quality, and guarantees your application is uniform, even at varying pressure levels.

What Role Does Air Pressure Play in Fan Efficiency?

Air pressure plays a vital role in fan efficiency by determining how much air the fan can move. When air pressure is high, the fan can generate more force, improving airflow and coverage. If pressure drops, the fan’s ability to push air diminishes, reducing efficiency. You’ll notice better performance when the system maintains ideal air pressure, ensuring consistent airflow and effective operation. Proper pressure is essential for maximum fan efficiency.

How Do Environmental Factors Influence Pattern Formation?

Imagine standing in a breeze that shifts unexpectedly, shaping your surroundings. Environmental factors like humidity, temperature, and surface texture directly influence pattern formation. You see how moisture can cause smudges or distort lines, while temperature variations might create subtle ripples or distortions. As you observe, you realize these unseen forces subtly manipulate every pattern, turning simple finishes into dynamic, unpredictable works of art shaped by nature’s invisible hand.

Are There Limits to Airflow Acceleration in Nozzles?

Yes, there are limits to airflow acceleration in nozzles. You can’t keep increasing the speed indefinitely because of factors like fluid compressibility, shock waves, and turbulence. As airflow approaches Mach 1, it becomes harder to accelerate further without creating pressure shocks that resist additional speed. These physical constraints define the maximum achievable flow rate and velocity, ensuring that airflow remains within safe and manageable limits.

Conclusion

Now that you understand how nozzles, fans, and patterns work together, imagine your favorite artist spraying paint. Each stroke relies on precise airflow and pattern control, just like in engineering. When you master these principles, you can create a flawless finish every time—like a painter perfecting their craft. Remember, mastering the physics behind the finish is like tuning an instrument; it takes practice, but the results are worth it.