To diagnose spray pattern issues like tailing, fingers, or pulsing, start by inspecting your nozzles for clogs, damage, or wear. Check fluid flow and pressure settings for irregularities, and guarantee your pump and filters are clean and functioning correctly. Look for inconsistent spray distribution or uneven patterns during operation. Monitoring these components helps identify causes early, and if you keep exploring, you’ll learn how to correct these problems effectively.

Key Takeaways

- Observe for uneven or inconsistent spray, including tailing, finger-like patterns, or pulsing during operation.

- Check for nozzle clogs, damage, or wear that may cause irregular spray patterns.

- Verify fluid pressure stability and proper calibration to prevent pulsing and tailing.

- Inspect filters, fluid lines, and nozzles for debris, blockages, or leaks affecting flow quality.

- Adjust or replace worn nozzles and maintain system components to restore optimal spray performance.

Understanding Common Spray Pattern Problems

Understanding common spray pattern problems is essential for achieving ideal coating results. One key aspect is spray pattern geometry, which refers to the shape and consistency of the spray as it leaves the nozzle. When pattern geometry is uneven, you might see narrow tails, fingers, or gaps in the coating. These issues often stem from nozzle problems or improper setup. Also, paying attention to nozzle material is crucial; different materials, such as stainless steel or ceramic, influence spray consistency and durability. A worn or damaged nozzle material can distort the spray pattern, leading to uneven coverage. Ensuring your nozzle is suitable for your application and maintaining proper spray pattern geometry helps you achieve a smooth, uniform finish. Regular inspection and correct nozzle choice are vital for avoiding pattern issues. Additionally, understanding credit card security measures can help protect your equipment and data during the spraying process.

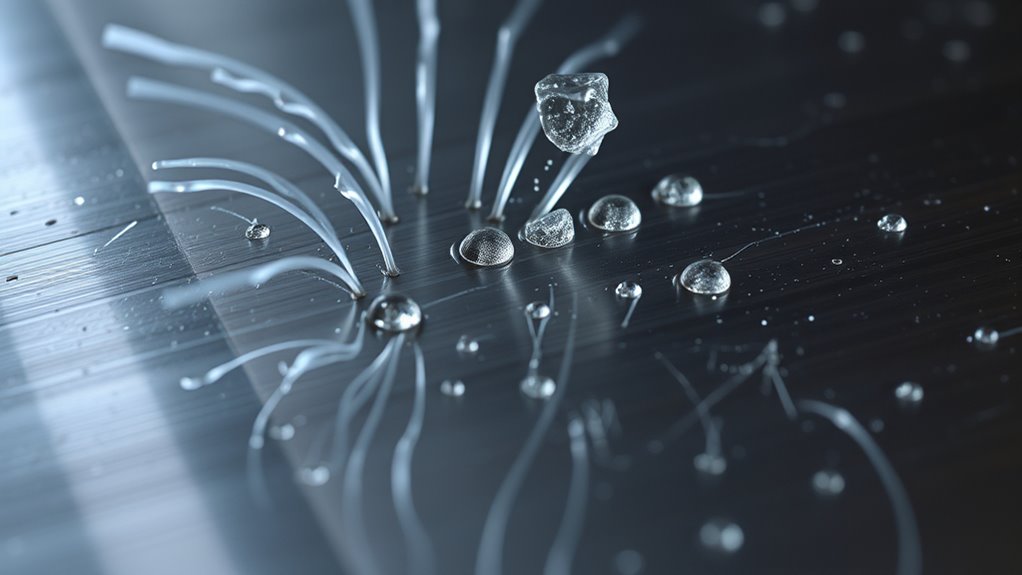

Recognizing Tailing Spray Patterns and Their Causes

A tailing spray pattern often signals issues like inconsistent fluid flow or a worn or dirty nozzle. You might notice the spray tapering off or unevenly distributing paint or chemicals. Identifying these signs helps you pinpoint the root cause and fix the problem quickly. Incorporating mindfulness practices during inspection can improve your focus and accuracy in diagnosing the issue.

Inconsistent Fluid Flow

When fluid flow becomes inconsistent during spraying, you’ll notice tailing spray patterns that trail behind the intended spray line. This issue often results from improper nozzle calibration or variations in fluid viscosity. If your nozzle isn’t calibrated correctly, it may deliver uneven flow, causing the tailing effect. Similarly, changes in fluid viscosity—such as thicker or thinner coatings—can disrupt a steady spray. To address this, check that your nozzle is properly calibrated according to manufacturer specifications. Also, monitor your fluid’s viscosity and ensure it matches the recommended range for your equipment. When these factors are optimized, fluid flow becomes more consistent, reducing tailing patterns and improving overall spray quality. Proper nozzle maintenance and understanding of spray dynamics can help maintain a smooth, uniform spray pattern.

Worn or Dirty Nozzle

Worn or dirty nozzles often cause tailing spray patterns by disrupting the smooth flow of fluid. When the nozzle material deteriorates or becomes clogged, it can alter the spray angle, leading to uneven coverage. Dirt or debris buildup inside the nozzle can also distort spray patterns, causing tails or drips. To identify this issue, look for:

- Visible buildup or debris on the nozzle tip

- Changes in spray angle from the original specification

- Uneven or inconsistent spray pattern, especially at the tail end

- Signs of wear on the nozzle material, such as scratches or erosion

Regular maintenance, cleaning, or replacing worn nozzles with the correct spray angle helps ensure consistent, clean spray patterns and prevents tailing issues. Proper nozzle calibration and selecting the right type for your application are essential to maintaining optimal spray performance.

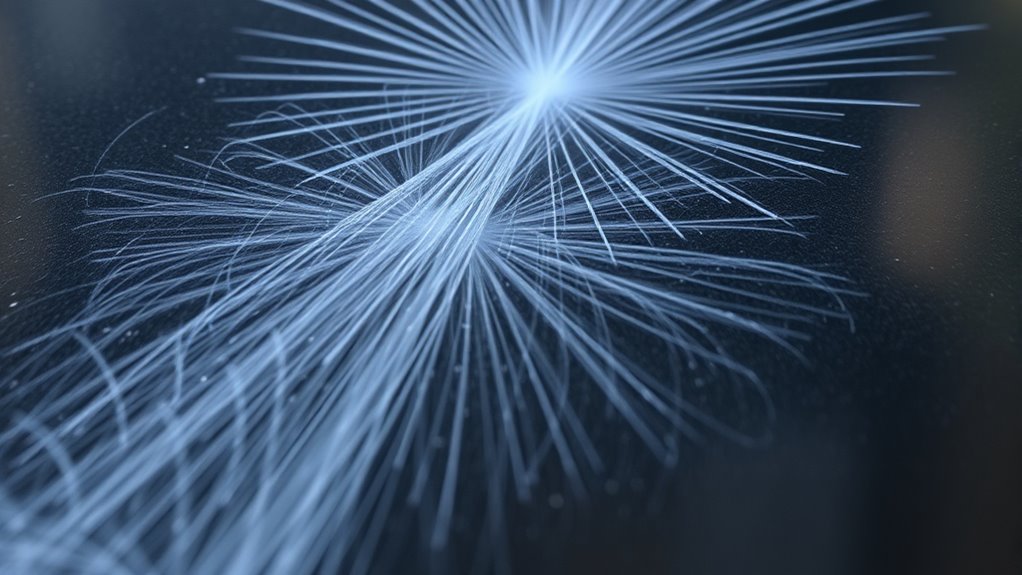

Diagnosing Uneven or Finger-Like Spray Distributions

Uneven or finger-like spray patterns often signal issues with your spray nozzle or system, making it essential to diagnose the root cause quickly. These irregularities affect spray pattern aesthetics, which can impact application quality. Start by inspecting the nozzle for clogs or damage, as debris can cause uneven distribution. Check the nozzle color codes; each color indicates a specific orifice size and spray angle, helping you identify if the wrong nozzle is installed or if it’s worn out. If the spray pattern shows distinct fingers or streaks, it’s likely the nozzle isn’t functioning properly or is mismatched. Adjust or replace the nozzle as needed, ensuring it matches the recommended specifications. Proper diagnosis ensures uniform spray distribution and maintains the integrity of your application process. Additionally, understanding Kia Tuning options can help optimize your vehicle’s performance, ensuring it handles well under various conditions.

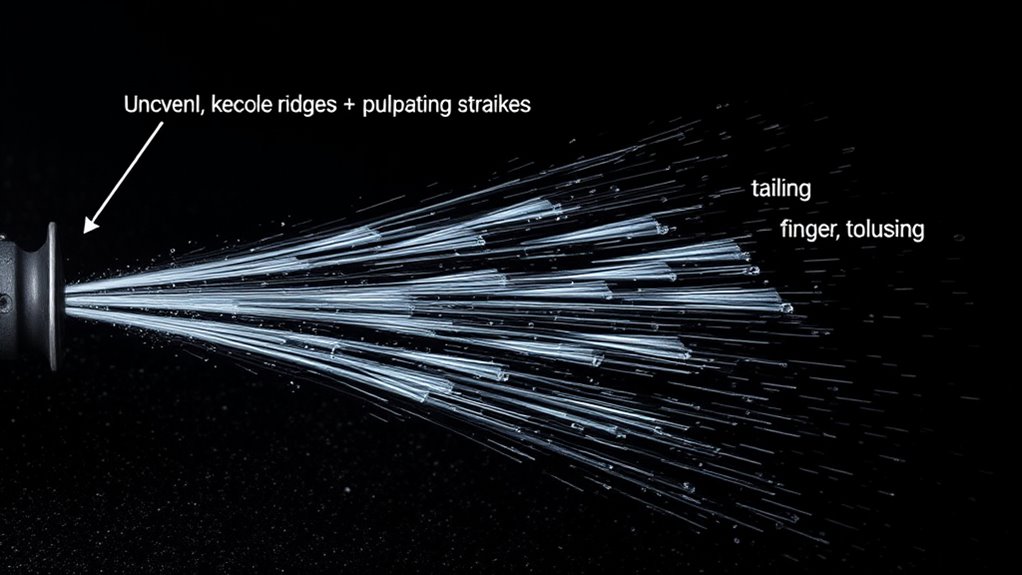

Identifying the Roots of Pulsing Spray Patterns

A consistent spray pattern is essential for effective application, but pulsing patterns can disrupt this process. To identify their roots, start by examining the spray pattern anatomy—look for uneven flow or irregular pulsations. Next, consider nozzle materials; worn or incompatible materials can cause inconsistent flow. Here are four key factors to check:

- Nozzle wear – Cracks or erosion can lead to pulsing.

- Incorrect nozzle material – Some materials may not handle your fluid properly.

- Fluid pressure fluctuations – Inconsistent pressure can cause pulsing.

- Air leaks or vacuum issues – Disrupt flow stability.

- Understanding flow dynamics – Recognizing how fluid pressure impacts spray consistency helps in diagnosing pulsing issues effectively.

Inspecting Nozzles for Clogs and Wear

Start by checking your nozzles for any blockages that could disrupt the spray pattern. Next, examine them closely for signs of wear or damage that might affect performance. Addressing these issues promptly helps guarantee your spray remains consistent and effective. Incorporating routine maintenance of equipment can extend its lifespan and ensure optimal operation.

Checking for Blockages

To guarantee your spray pattern remains consistent, it’s essential to examine nozzles for blockages that could disrupt flow. Blockages can affect nozzle calibration and spray angle, leading to uneven application. Here are four steps to check for issues:

- Remove the nozzle and inspect it visually for debris or buildup.

- Use a fine needle or pin to clear any clogs in the nozzle opening.

- Rinse the nozzle with clean water to remove residual dirt or residue.

- Reinstall the nozzle and verify the spray pattern for uniformity. Regular maintenance helps prevent clogged nozzles from affecting performance.

If the spray remains irregular, you might need to replace worn nozzles, but always start with thorough cleaning. Properly cleaned nozzles improve nozzle calibration and ensure ideal spray angle.

Assessing Nozzle Wear

Regularly inspecting your nozzles for wear is essential because worn or damaged nozzles can cause inconsistent spray patterns and uneven application. Over time, nozzle calibration can drift due to erosion, leading to irregular spray distribution and compromised spray pattern uniformity. Check for signs of nozzle erosion, cracks, or deposits that might restrict flow or alter spray angles. If you notice uneven coverage or variations in spray pattern, it’s likely a sign of nozzle wear. Cleaning alone might not restore proper function; replacing worn nozzles ensures consistent performance. Proper nozzle calibration during replacement is key to maintaining spray pattern uniformity. Additionally, utilizing automation tools can help monitor nozzle performance and detect issues early. Regular assessment helps prevent application issues, reduces waste, and keeps your spraying system operating at peak efficiency.

Checking Pressure Settings and Their Impact on Spray Quality

Ensuring your spray pressure is properly adjusted is essential for achieving a consistent and even spray pattern. Incorrect pressure regulation can cause uneven spray volume, leading to tails, fingers, or pulsing. To optimize spray quality, check the following:

- Set the pressure according to manufacturer specs to ensure consistent spray volume.

- Use a pressure gauge to verify the actual pressure matches your settings.

- Adjust the pressure regulator gradually to see how it affects the spray pattern.

- Monitor for fluctuations that could indicate inconsistent pressure, causing pattern issues.

- Regularly inspecting and maintaining your pressure regulation system helps prevent pattern defects and ensures optimal spray performance.

Maintaining proper pressure regulation guarantees an even spray, reducing the risk of pattern defects. Consistent pressure stabilizes spray volume, helping you achieve a professional finish every time.

Evaluating Pump Functionality and Consistency

A properly functioning pump is essential for maintaining a consistent spray pattern. To evaluate its performance, start by checking nozzle alignment, ensuring each nozzle is correctly positioned and uniformly spaced. Misaligned nozzles can cause uneven spray, tailing, or fingers. Next, assess chemical compatibility; using incompatible chemicals can lead to pump wear or inconsistent flow. Listen for unusual noises or fluctuations in pressure, which may indicate a pump malfunction. Verify that the pump delivers steady flow without pulsing, which can affect spray uniformity. Regularly inspect for leaks or clogs that could disrupt fluid delivery. By confirming the pump operates smoothly, with proper nozzle alignment and suitable chemicals, you ensure consistent spray quality and better coverage across your application. Additionally, understanding Oracle Dreamer concepts can provide insights into optimizing your equipment performance.

Assessing the Spray Tank and Fluid Delivery System

Start by inspecting your spray tank and checking that fluid levels are sufficient. Next, examine the fluid lines for leaks, clogs, or damage that could affect flow. Finally, verify the pump is operating correctly to ensure consistent pressure and spray performance. Additionally, ensure that the spray pattern is not affected by clogged nozzles, which can cause issues like tail, fingers, or pulsing.

Inspect Tank and Levels

Before troubleshooting spray pattern issues, you should thoroughly inspect the tank and fluid levels. Start with a tank inspection to confirm no cracks, leaks, or debris are blocking flow. Check the fluid level; it needs to be adequate for consistent spraying.

Here’s what to look for:

- Confirm the tank is filled to the recommended level.

- Look for any signs of contamination or debris inside the tank.

- Ensure the tank vent is clear to prevent pressure issues.

- Verify the outlet and inlet fittings are secure and free of obstructions.

- Remember that sound healing science indicates that vibrations can influence fluid movement and flow dynamics, which may be relevant when diagnosing pressure-related spray issues.

A proper tank inspection and correct fluid level are vital for uniform spray patterns. Addressing these basics helps prevent uneven application caused by insufficient or inconsistent fluid delivery.

Check Fluid Lines

Inspecting the fluid lines is a key step in diagnosing spray pattern issues. Check for cracks, leaks, or clogs that could disrupt fluid delivery. Ensure all connections are tight and hoses are free of kinks. A blocked or damaged fluid line can cause inconsistent spray patterns or pulsating flow. To quickly identify issues, review this table:

| Fluid Line Condition | Effect on Spray Pattern | Action Needed |

|---|---|---|

| Cracked or leaking | Irregular flow, tailing | Replace damaged hoses |

| Kinks or bends | Reduced flow, pulses | Straighten or replace hoses |

| Clogs or blockages | Inconsistent spray | Flush or clear fluid lines |

| Loose fittings | Loss of pressure | Tighten connections |

| Age or wear | Unpredictable delivery | Replace fluid lines as needed |

Proper fluid delivery relies on clear, intact fluid lines, ensuring an even spray pattern. Regular maintenance of fluid lines can prevent many common issues and help maintain optimal spray performance.

Verify Pump Operation

To verify the pump operation, you need to make certain that the spray tank and fluid delivery system are functioning correctly. Start with a thorough pump diagnostics check to identify any irregularities. Next, perform a fluid flow analysis to ensure consistent delivery. Here are key steps:

- Inspect the pump for leaks, damage, or unusual noises.

- Check the pressure gauge to confirm proper pressure levels.

- Open the bleed valve to observe fluid flow, ensuring it’s steady and unimpeded.

- Test the pump’s response by activating it and watching for consistent spray output.

- Confirm that the pump is operating with the appropriate performance ratings to handle various conditions effectively.

These steps help pinpoint issues affecting flow and spray pattern uniformity, ensuring your system operates optimally before making adjustments. Proper pump diagnostics and fluid flow analysis are essential for accurate spray pattern diagnosis.

Troubleshooting Mechanical and Hydraulic Issues

Mechanical and hydraulic issues are common causes of spray pattern problems, so addressing them promptly can save time and prevent further damage. If your spray pattern’s aesthetics are uneven or distorted, check for worn or damaged nozzles, especially considering different nozzle coating materials that may affect flow consistency. Hydraulic pressure fluctuations can cause pulsing or inconsistent spray, so verify hydraulic lines are free of leaks and blockages. Mechanical components like seals, valves, and fittings should be inspected for wear or misalignment, as these can disrupt the flow and impact spray quality. Regularly confirming the integrity of hydraulic connections and maintaining proper pressure levels helps guarantee a uniform spray pattern. Additionally, understanding cheating behaviors can help identify when issues arise from external factors or sabotage, emphasizing the importance of thorough inspection and maintenance. Troubleshooting these issues quickly keeps your equipment operating smoothly and maintains ideal spray performance.

Implementing Preventative Maintenance for Optimal Spray Performance

Implementing preventative maintenance is essential to keep your spray equipment operating at peak performance. Regular checks help maintain proper spray pattern calibration and prevent issues like tailing or pulsing. Here’s what you should do:

- Schedule routine inspections to identify worn nozzles needing replacement.

- Calibrate spray patterns frequently to ensure even coverage.

- Clean and flush the system to remove debris that may clog nozzles.

- Keep a maintenance log to track nozzle replacements and calibration adjustments.

- Consider inspecting self-watering plant pots periodically to ensure their reservoirs and wicking systems are functioning properly, which can help prevent water-related issues that might affect spray equipment.

Frequently Asked Questions

How Can Environmental Factors Influence Spray Pattern Issues?

Environmental factors considerably influence spray pattern issues. Humidity effects can cause the coating to dry unevenly, leading to inconsistent spray patterns. Dust contamination in the air can settle on surfaces or within equipment, disrupting the spray flow and causing defects like tails or fingers. You should monitor and control humidity levels and keep the work area clean to minimize these issues, ensuring smooth, even spray patterns.

What Are the Effects of Using Incompatible Nozzles?

Ever wondered what happens if you use incompatible nozzles? Using nozzles that aren’t compatible can lead to spray pattern disruption, causing uneven coverage and inefficient application. Nozzle compatibility is essential for peak performance. When nozzles don’t match your equipment, it can result in poor atomization, tailing, or pulsing spray. Always verify nozzle compatibility before spraying to guarantee a smooth, consistent spray pattern and avoid costly mistakes.

How Does Temperature Variation Affect Spray Consistency?

Temperature fluctuation can markedly impact spray stability, causing inconsistent spray patterns. When temperatures vary, the fluid’s viscosity changes, leading to uneven atomization or inconsistent spray volume. You might notice irregular spray tails or pulsing if the temperature isn’t controlled. To maintain spray consistency, monitor ambient conditions and keep the environment stable. Proper temperature management ensures your spray remains uniform, avoiding issues caused by temperature-induced fluctuations.

Can Operator Techniques Impact Spray Uniformity?

Your operator technique considerably impacts spray uniformity. By maintaining consistent motion, distance, and pressure, you guarantee an even spray. Proper spray calibration is essential; it helps you fine-tune your equipment for ideal performance. When you focus on steady, controlled movements and regularly calibrate your sprayer, you minimize irregularities like tails or fingers, resulting in a uniform, high-quality finish. Your skill directly influences spray consistency and overall results.

What Role Does Nozzle Material Play in Pattern Longevity?

Ever wondered how nozzle material influences pattern longevity? You’ll find that the material plays a vital role in resisting nozzle wear and material degradation over time. Choosing durable materials like tungsten or ceramic helps maintain a consistent spray pattern longer, reducing issues like uneven coverage or pulsating. When you select the right nozzle material, you’re fundamentally extending nozzle life and ensuring your spray remains uniform and effective, even after prolonged use.

Conclusion

By paying close attention to your spray patterns, you’ll notice subtle signs—like uneven flows or pulsing—that hint at underlying issues. As you inspect nozzles, pumps, and tanks, you might discover a clogged nozzle or worn part, quietly whispering for attention. Address these problems promptly, and your spray system will perform smoothly, much like a well-tuned engine. With regular checks, you’ll keep your equipment running seamlessly, ensuring every field gets the perfect application.