When choosing between airless and HVLP paint sprayers, it’s important to understand their differences. Airless sprayers use high pressure for quick coverage on large surfaces, but produce more overspray and mist. HVLP sprayers operate at lower pressure, offering better control and a smooth finish, ideal for detailed work. Consider your project size and desired quality. Keep exploring to find out which sprayer fits your needs best.

Key Takeaways

- Airless sprayers cover large areas quickly with high pressure, while HVLP sprayers offer more control for detailed work at lower pressure.

- Airless models produce broader spray patterns suitable for exterior surfaces; HVLP provides finer finishes ideal for interior and furniture projects.

- HVLP sprayers are easier to operate, more portable, and generally cost less, whereas airless units require more setup and maintenance.

- HVLP sprayers generate less overspray and mist, making them safer and more environmentally friendly; airless sprayers create more paint waste.

- For speed and efficiency on big projects, airless sprayers are preferred; for precision and quality on smaller surfaces, HVLP is the better choice.

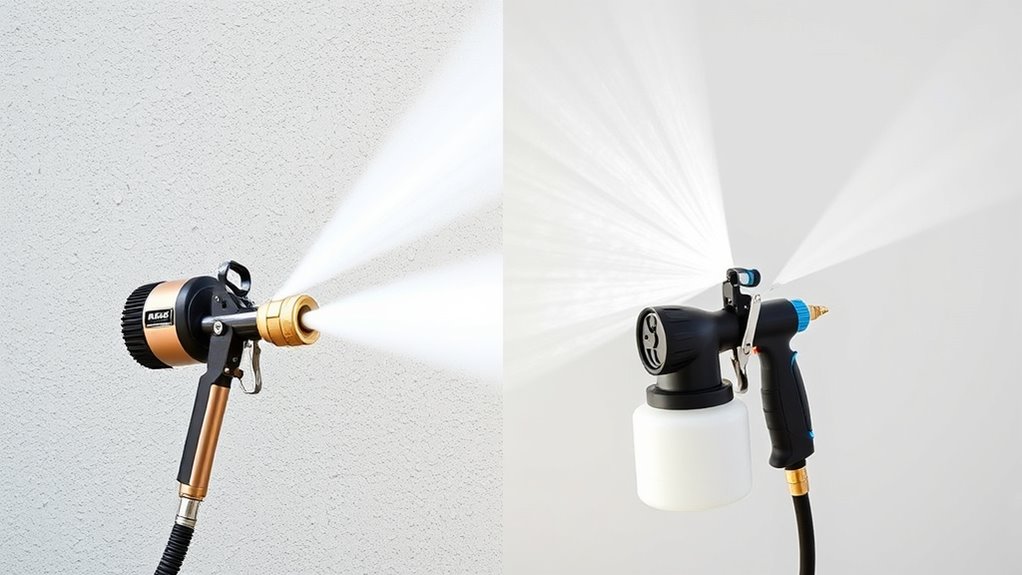

How They Operate: Airless Vs HVLP

Understanding how each sprayer works is essential to choosing the right tool for your project. Airless and HVLP sprayers operate differently, impacting safety considerations and environmental impact. An airless sprayer uses a high-pressure pump to atomize paint directly from the tip, delivering fast coverage with minimal overspray. It’s powerful but can create more mist, requiring careful handling to prevent accidents. HVLP sprayers, on the other hand, use a turbine or compressed air to produce a lower-pressure, finely atomized spray, reducing overspray and waste. This makes them safer to operate and more environmentally friendly, as less paint gets wasted and airborne. Your choice depends on understanding these operational differences, especially how safety and environmental factors influence the overall project.

Typical Uses and Projects

When choosing between airless and HVLP sprayers, consider the types of projects you’ll tackle and the surfaces you’ll work on. Some sprayers excel with larger areas or specific materials, making them better suited for certain applications. Understanding your project scale and surface needs helps you pick the right tool for efficient results. Additionally, GMC tuning techniques can optimize equipment performance for various painting tasks, ensuring consistent application and finish quality.

Ideal Application Types

Airless and HVLP paint sprayers each excel in different types of projects, making them suited for specific application needs. If you’re working on large exterior surfaces or thick coatings, an airless sprayer is ideal due to its high pressure and fast coverage. It’s perfect for priming techniques on walls, fences, or decks. HVLP sprayers, on the other hand, are better for detailed interior work, furniture, or cabinetry, where precision is essential. They produce less overspray, making environmental considerations easier to manage. HVLP systems also allow better control over the spray pattern, reducing waste and ensuring a smooth finish. Additionally, the material of the spray components, such as aesthetic hooks and wall organization solutions, can influence the choice, especially when working with delicate surfaces. Choose the sprayer based on your project size, surface material, and environmental impact to achieve the best results efficiently.

Suitable Surface Materials

Choosing the right surface material can considerably influence the success of your painting project. Both airless and HVLP sprayers work best on surfaces that have been properly prepped to ensure even coverage. Smooth, solid materials like wood, metal, or drywall are ideal, as they allow for better paint adhesion and minimal overspray. Avoid applying paint on rough or uneven surfaces without proper surface prep, which can lead to uneven finishes and wasted paint. Environmental impact is also a key consideration; HVLP sprayers typically produce less overspray and waste, making them more eco-friendly for projects involving delicate or protected surfaces. Understanding the type of surface material and how to prepare it guarantees optimal results and reduces unnecessary environmental footprint. Additionally, considering the airflow and pressure capabilities of each sprayer can help determine the most efficient choice for different surface types and project scales.

Project Scale Compatibility

Different project scales and types determine which sprayer is most suitable. For small to medium projects, like furniture or cabinets, HVLP sprayers excel because they offer precise control and excellent surface compatibility without overspray. They’re ideal when you need a fine finish on detailed surfaces. Larger projects, such as decks, fences, or exterior walls, demand the power of airless sprayers. They cover extensive surfaces quickly and handle thicker coatings, making them suited for substantial project scales. Understanding your surface compatibility is essential; airless sprayers work well with rougher surfaces and thicker paints, while HVLP sprayers are better for smooth, detailed surfaces. Choosing the right sprayer depends on your project scale and the surface’s needs, ensuring efficient application and a quality finish. Additionally, selecting a sprayer that aligns with Mazda Tuning principles can help achieve a more polished and professional outcome.

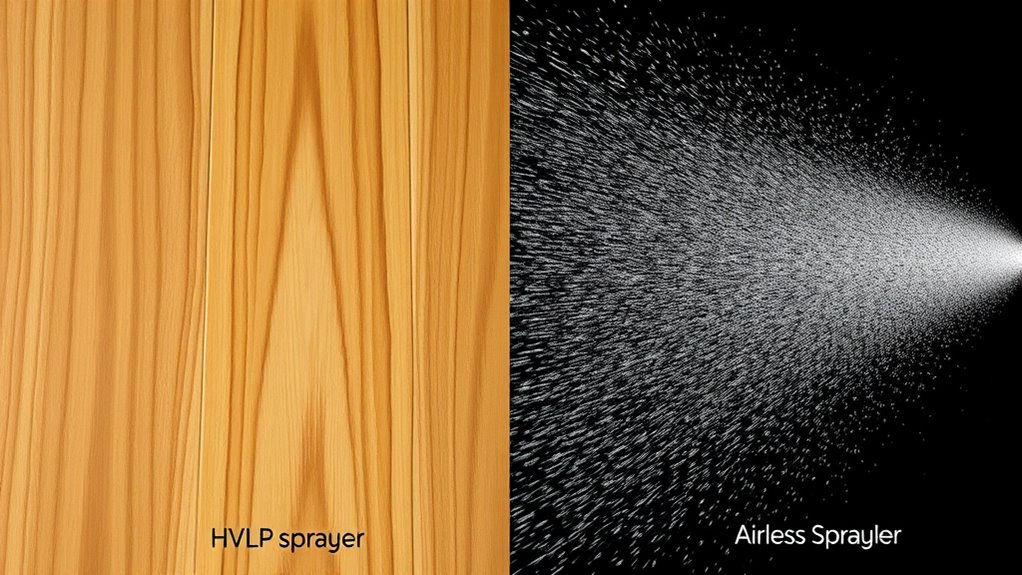

Spray Pattern and Finish Quality

When it comes to spray pattern and finish quality, the type of sprayer you choose considerably influences your results. Airless sprayers produce a broad, consistent spray, ideal for large surfaces, but may limit texture variation. HVLP sprayers offer finer control, allowing you to create detailed textures and smooth color blending.

- Airless sprayers tend to deliver a more uniform finish but can sometimes cause overspray or uneven texture variation.

- HVLP sprayers excel at detailed work, providing better control over spray pattern for smoother, more refined finishes.

- The choice affects how well you can achieve the desired texture and seamless color blending, influencing the overall quality of your project.

Application Speed and Coverage

You’ll notice that airless sprayers generally work faster, covering larger areas quickly, while HVLP models may take longer but offer more control. Material coverage rate varies between the two, affecting how efficiently you can complete your project. Achieving even surface uniformity depends on selecting the right sprayer for your speed and coverage needs. Additionally, understanding the effectiveness of eye patches can help in choosing the appropriate skincare tools to complement your painting project.

Spray Speed Efficiency

Are you looking to complete your painting project quickly and efficiently? Spray speed efficiency plays a vital role in this. Airless sprayers typically cover larger areas faster, reducing overall project time. HVLP sprayers, while slower, offer more control for detailed work. Consider these points:

- Application speed impacts how quickly paint dries, affecting overall project duration.

- Coverage area varies, with airless sprayers generally providing broader coverage in less time.

- Both types influence environmental impact by minimizing overspray and waste.

- Faster spraying reduces paint drying time on surfaces, speeding up project completion.

- Efficient coverage helps lower solvent emissions, making your project more eco-friendly.

- Proper maintenance and understanding of heat pump features can improve efficiency and reduce operational issues during your projects.

Choosing the right sprayer depends on your project’s scale and detail, but both can optimize spray speed for better results.

Material Coverage Rate

Material coverage rate directly influences how efficiently your paint application proceeds. The spray nozzle plays a pivotal role here, as its size and design determine how much paint flows and covers surfaces quickly. HVLP sprayers typically have larger nozzles, which can handle higher paint viscosity, allowing for faster coverage on thicker paints. Conversely, airless sprayers use high pressure and a narrower spray pattern, providing rapid application over large areas. Your paint viscosity also impacts coverage; thinner paints spray more evenly and cover more area per pass, increasing efficiency. Understanding these factors helps you choose the right sprayer for your project, ensuring ideal coverage without sacrificing quality. Ultimately, the right combination of spray nozzle and paint viscosity will maximize your application speed and coverage. Additionally, considering Kia Tuning options can help optimize your vehicle’s performance, just as selecting the correct spray equipment optimizes your painting results.

Surface Uniformity Achieved

Surface uniformity depends heavily on application speed and coverage efficiency, which are directly influenced by the type of sprayer you choose. An airless sprayer typically covers large areas quickly, promoting consistent primer adhesion and a smooth surface. Conversely, HVLP sprayers offer more control, resulting in a finer, more even finish that enhances surface smoothness. Additionally, understanding the color accuracy of your sprayer can further improve the final appearance by ensuring true-to-color application.

- Airless sprayers deliver rapid coverage, reducing streaks and uneven patches.

- HVLP sprayers allow for detailed control, minimizing overspray and ensuring even primer application.

- The choice impacts how well primer adheres and how smooth the final surface looks, affecting overall quality.

Ease of Use and Setup

When it comes to ease of use and setup, HVLP paint sprayers generally have an advantage because they are designed to be lightweight and straightforward to operate. Their ergonomic design minimizes fatigue, allowing you to work longer without discomfort. You’ll find that setting up an HVLP sprayer is quick—you typically just need to connect the spray gun, adjust the pressure, and start spraying. Portability is another benefit, as these units are compact and easy to move around your workspace. Unlike airless sprayers, HVLP systems often require fewer accessories and less setup time, making them ideal for smaller projects or DIY tasks. Overall, their user-friendly design ensures you can get started fast and with minimal effort. Additionally, their security measures help protect your equipment and project data during operation.

Cost and Maintenance

While HVLP paint sprayers often cost less upfront and require fewer maintenance tasks, airless sprayers tend to have higher initial prices and can incur more ongoing expenses. Your budget considerations play a key role here, especially since maintenance costs for airless models can add up over time. HVLP sprayers generally need less frequent cleaning and fewer replacement parts, making them more affordable long-term. Conversely, airless sprayers may require more robust maintenance, including replacing seals and filters regularly. Proper maintenance is essential to prolong the lifespan of both sprayer types and ensure consistent performance.

Choosing the Right Sprayer for Your Needs

Choosing the right sprayer depends on your specific painting needs, budget, and how often you’ll be using it. If you value sprayer portability, an HVLP sprayer offers lightweight design and easy maneuverability for small projects or tight spaces. Conversely, if you’re tackling large surfaces and need high efficiency, an airless sprayer might be more suitable, though it’s generally less portable. Noise levels also matter; HVLP sprayers tend to operate quietly, making them ideal for indoor use or shared spaces. Consider how often you’ll use the sprayer—frequent use may justify investing in a durable airless model, while occasional projects could be handled with a more portable, quieter HVLP system. Matching your needs with these factors ensures excellent results and ease of use. Additionally, understanding the different spray technologies can help you select the most appropriate tool for your projects.

Frequently Asked Questions

Which Sprayer Is Better for Detailed or Intricate Work?

For detailed or intricate work, you’ll want a sprayer that offers fine detail and precision control. HVLP sprayers excel here because they deliver a lower pressure, allowing you to control the spray with greater accuracy. Airless sprayers, while powerful, tend to produce broader, less controlled streams. So, if your project demands intricate detail, an HVLP sprayer is the better choice, giving you the control you need for a flawless finish.

How Do Weather Conditions Affect Each Sprayer’S Performance?

Ever wondered how weather sneaks up on your painting project? Humidity impacts airless sprayers by causing inconsistent spray patterns, while HVLP sprayers might struggle with overspray in high humidity. Temperature effects can cause paint to dry too quickly or too slowly, affecting both sprayers’ finish. You need to observe weather closely, adjusting your approach to ensure flawless results, no matter the conditions outside.

Can HVLP or Airless Sprayers Handle Thick or Textured Paints?

You might wonder if HVLP or airless sprayers can handle thick or textured paints. Generally, airless sprayers are better suited because they handle higher paint viscosity without clogging, making them ideal for thicker or textured coatings. HVLP sprayers often clog when used with thick paints, as they require lower viscosity. To prevent clogging, always thin your paint appropriately and choose the right sprayer for your project.

What Safety Precautions Are Necessary for Each Type of Sprayer?

When using either sprayer, you should wear personal protective equipment like goggles, masks, and gloves to prevent paint inhalation or skin contact. Confirm electrical safety by inspecting cords and connections for damage before use. Keep the work area well-ventilated, and follow manufacturer instructions for safe operation. Always disconnect power when cleaning or servicing, and handle paints carefully to avoid spills or accidents.

How Do Noise Levels Compare Between Airless and HVLP Sprayers?

Did you know that HVLP sprayers are typically 30% quieter than airless sprayers? When comparing noise levels, HVLP models produce less sound, making them ideal for indoor use or noise-sensitive environments. The sound comparison shows that airless sprayers generate louder noise, which can be disruptive. If you want a quieter operation, an HVLP sprayer is your best choice, offering a significant reduction in noise during painting projects.

Conclusion

Choosing between airless and HVLP sprayers depends on your project needs. Did you know that airless sprayers can cover up to 1,500 square feet per hour, making them ideal for large jobs? HVLP sprayers, on the other hand, offer precision for detail work. Understanding their differences helps you pick the right tool, saving time and ensuring a professional finish. Make your choice wisely, and you’ll achieve great results every time!